Magnetic control type current collecting device capable of improving gas extraction concentration and operation method thereof

A flow collecting device and gas drainage technology, which is applied in the direction of gas discharge, safety devices, mining equipment, etc., can solve the problems of low concentration of gas drainage and little influence of the scalar amount of gas drainage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

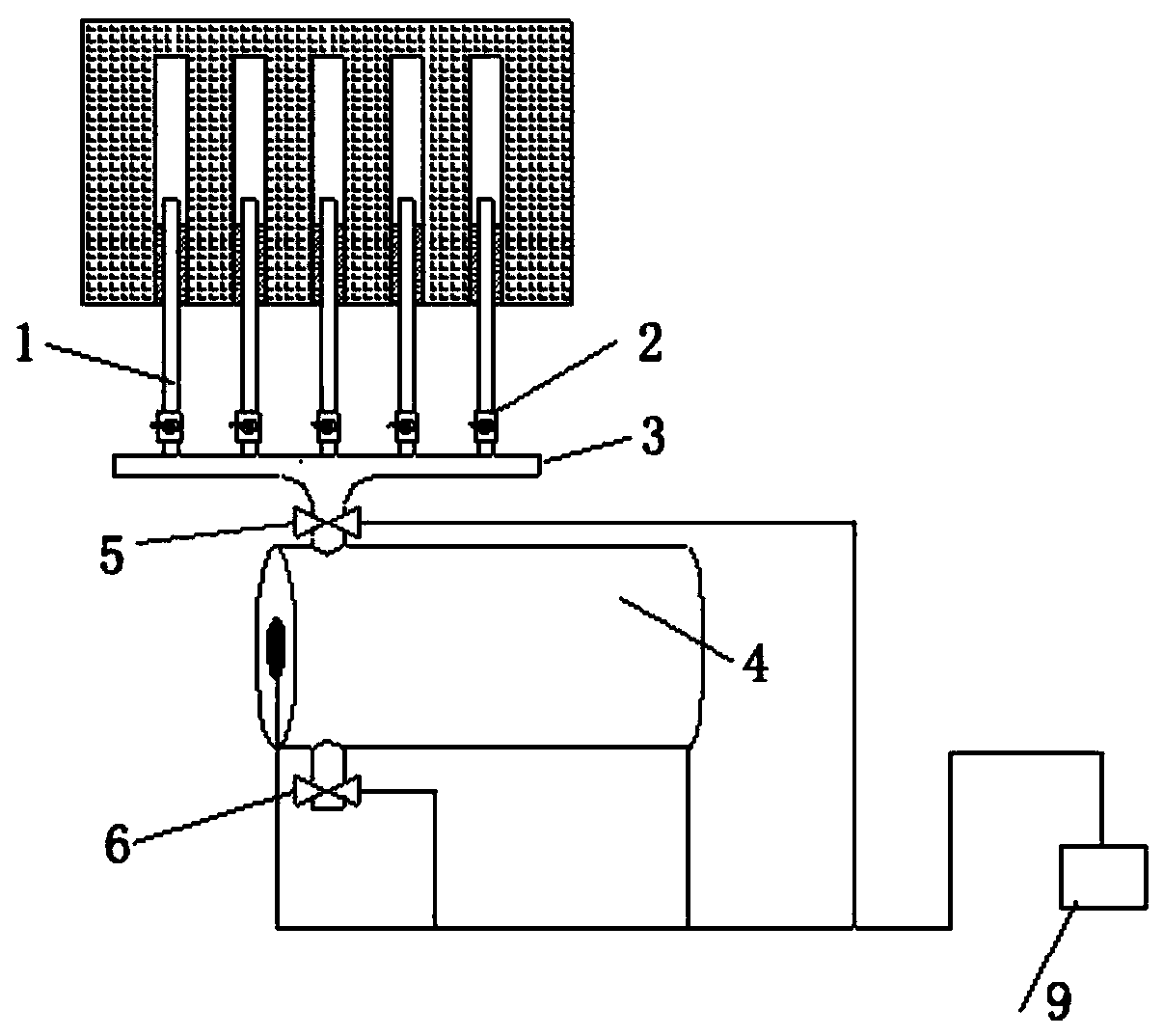

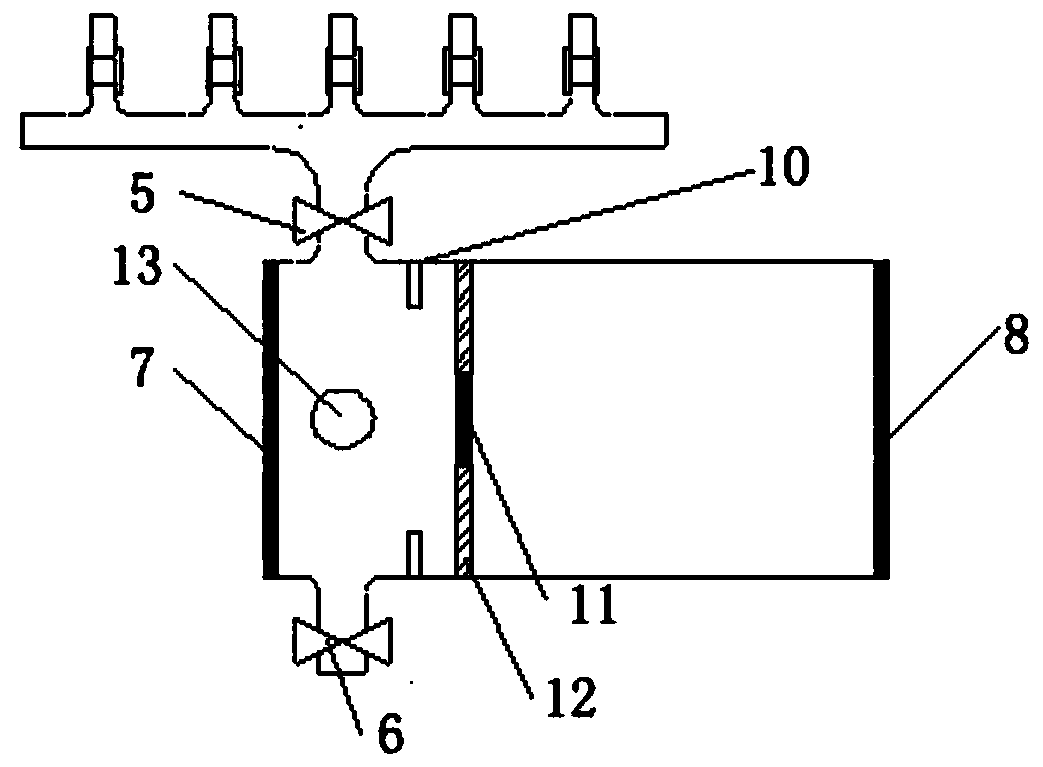

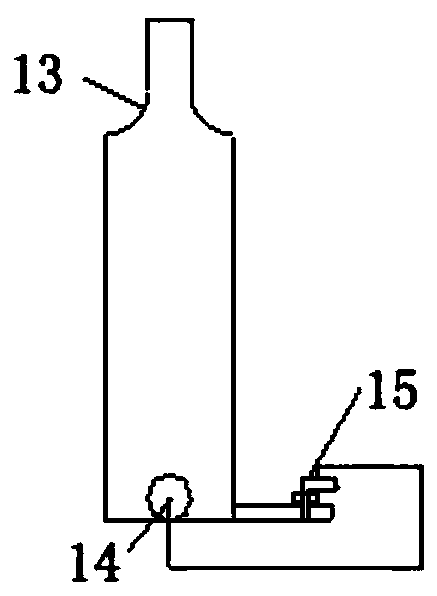

[0026] The present invention will be further described below in conjunction with accompanying drawing.

[0027] Such as Figure 1-Figure 4As shown, a magnetically controlled current collecting device for increasing the concentration of gas extraction includes a extraction branch pipe 1 that penetrates into the coal seam at one end, and the other end of the extraction branch pipe 1 is connected to the air inlet of the gas extraction device 3 through a connecting valve 2 , the connection valve 2 can seal the extraction branch pipe 1 and the gas extraction device 3, so as to ensure that the gas will not leak when the gas gas enters the gas extraction device from the extraction branch pipe 1 through the connection valve 2;

[0028] It also includes a magnetron tank 4 and a control device 9. The magnetron tank 4 is used as a gas-gathering place to ensure good sealing. Install the intelligent control valve Ⅰ5, and install the intelligent control valve Ⅱ6 on the pipeline of the gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com