Refrigerant recovery device

A technology of refrigerant and liquid storage device, which is applied in the direction of refrigerants, refrigerators, refrigeration components, etc., can solve the problems of complicated operation, large amount of refrigerant used, and high price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

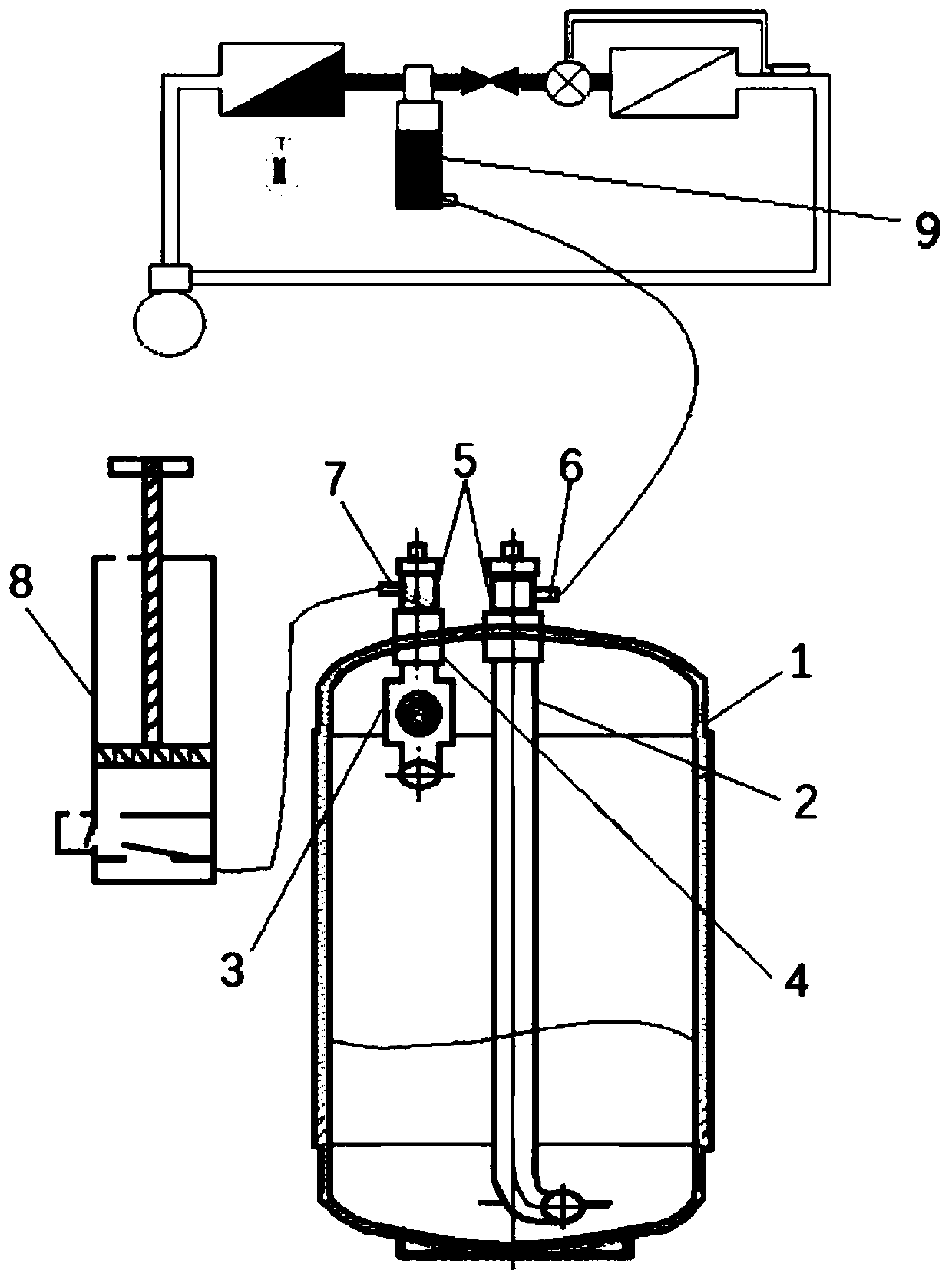

[0011] Such as figure 1 As shown, a device for recovering refrigerant includes a liquid storage device and a vacuum pumping device. The liquid storage device is composed of a liquid storage tank 1, a liquid inlet pipe 2, a gas-liquid separation device 3, an air outlet pipe 4, and a needle valve 5. The outer wall of the liquid storage tank 1 is a double-layer structure, with a vacuum insulation layer between the two layers, which can ensure that the liquid refrigerant recovered in the liquid storage tank 1 will not be vaporized due to temperature rise; the liquid inlet pipe 2 extends into the liquid storage tank At the bottom of the tank 1, the outlet pipe 4 extends into the top of the liquid storage tank 1 and a gas-liquid separation device 3 is installed at the front end. The density of the floating ball in the gas-liquid separation device 3 is greater than that of the gaseous refrigerant and less than that of the liquid refrigerant, which can ensure the storage The air in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com