A thermal insulation penetrating device for a hot chamber

A technology of hot chamber and thermal insulation layer, applied in the field of post-processing, can solve the problems of pipeline penetration without thermal insulation function and poor sealing performance, and achieve the effects of good system safety, reliable sealing and good overall sealing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

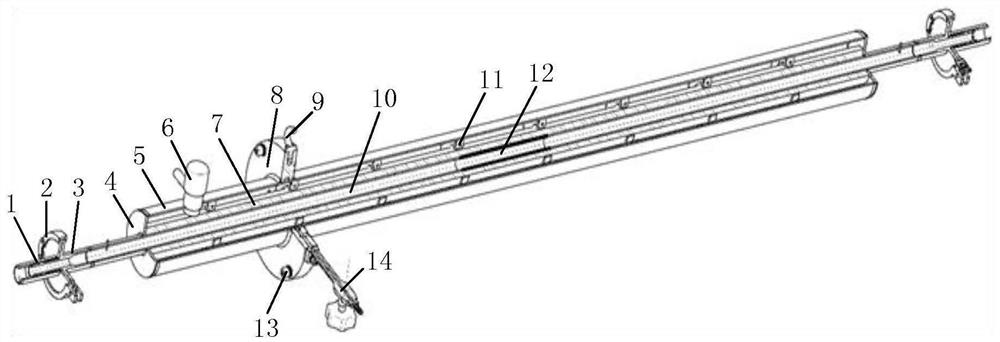

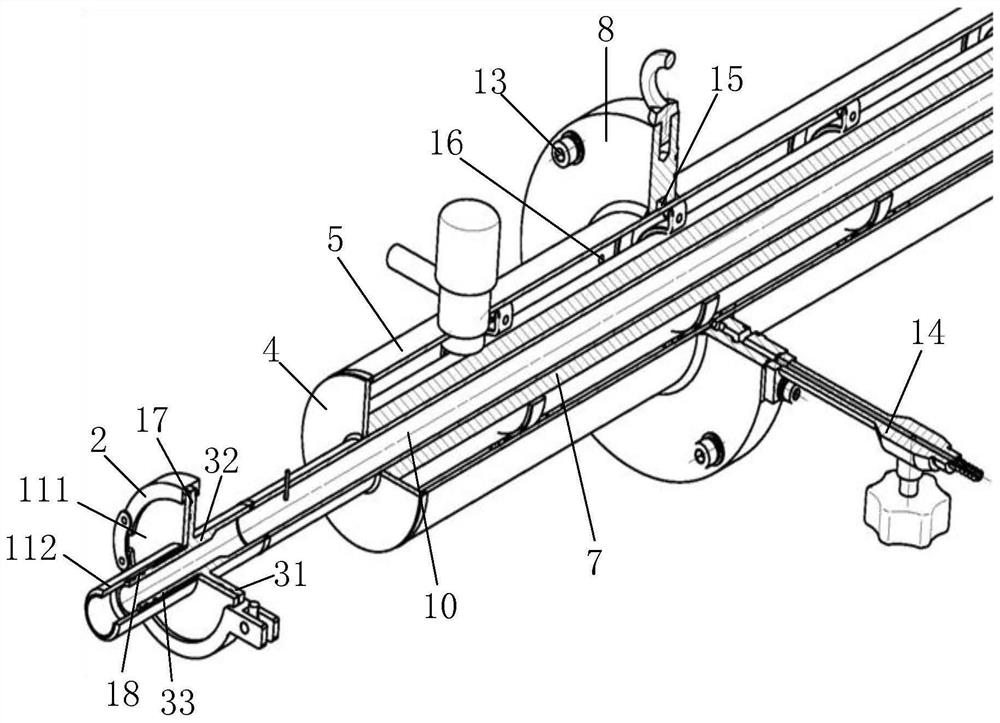

[0049] Such as Figure 1-Figure 2 As shown, a thermal insulation penetrating device for a hot cell includes a quick release joint 1 and an installation assembly;

[0050] The installation assembly includes an outer tube 5 and an inner tube 10, the outer tube 5 and the inner tube 10 are hollow structures, the inner tube 10 is arranged inside the outer tube 5, and the outer tube 5 and the inner tube 10 form a Annular vacuum interlayer, an insulating layer 7 is arranged between the outer tube 5 and the inner tube 10, the two ends of the inner tube 10 protrude from the two ends of the outer tube 5, and the ends of the outer tube 5 and the inner tube 10 are connected by a sealing plate 4, the sealing plate 4 is an annular plate, the inner side and the outer side of the annular plate are respectively welded with the outer wall of the inner tube 10 and the end of the outer tube 5, and the two ends of the inner tube 10 are welded with sealing A joint 3, the outer wall of the outer pi...

Embodiment 2

[0060] Such as Figure 1-Figure 2 As shown, the embodiment is based on Embodiment 1, and the flange 8 is provided with a pressure monitoring assembly 14, which is used to monitor the pressure in the annular vacuum interlayer, and the pressure monitoring assembly 14 adopts valves, gauges and electronic vacuum The independent structure or combined structure of the meter has the function of charging and deflation and air pressure display; the inner side of the flange 8 is provided with an annular air cavity 15, and the mounting surface of the flange 8 is provided with a double-channel seal. 8 is provided with a penetrating air passage for communicating with the double-channel seal and the annular air chamber 15, and the outer wall of the outer tube 5 is provided with a plurality of vent holes 16, and the vent holes 16 are arranged inside the annular air chamber 15, and the vent holes 16 is just wrapped by the annular air chamber 15, and is used to communicate with the annular air...

Embodiment 3

[0063] Such as Figure 1-Figure 3 As shown, the embodiment is based on embodiment 1 or embodiment 2. A plurality of heat-insulating supports 11 are arranged between the thermal insulation layer 7 and the outer pipe 5, which is a "recursive bending" structure, which increases the contact area while reducing the contact area. The heat dissipation distance, and the structure has a certain degree of elasticity, which can isolate vibration and absorb noise, so that the thermal insulation penetration device has good vibration resistance and noise reduction performance. The heat insulation support is made of glass fiber, alumina fiber or Made of mullite fiber; the inner pipe 10 is provided with an expansion joint 12; the flange 8 is provided with a suspension ring 9 .

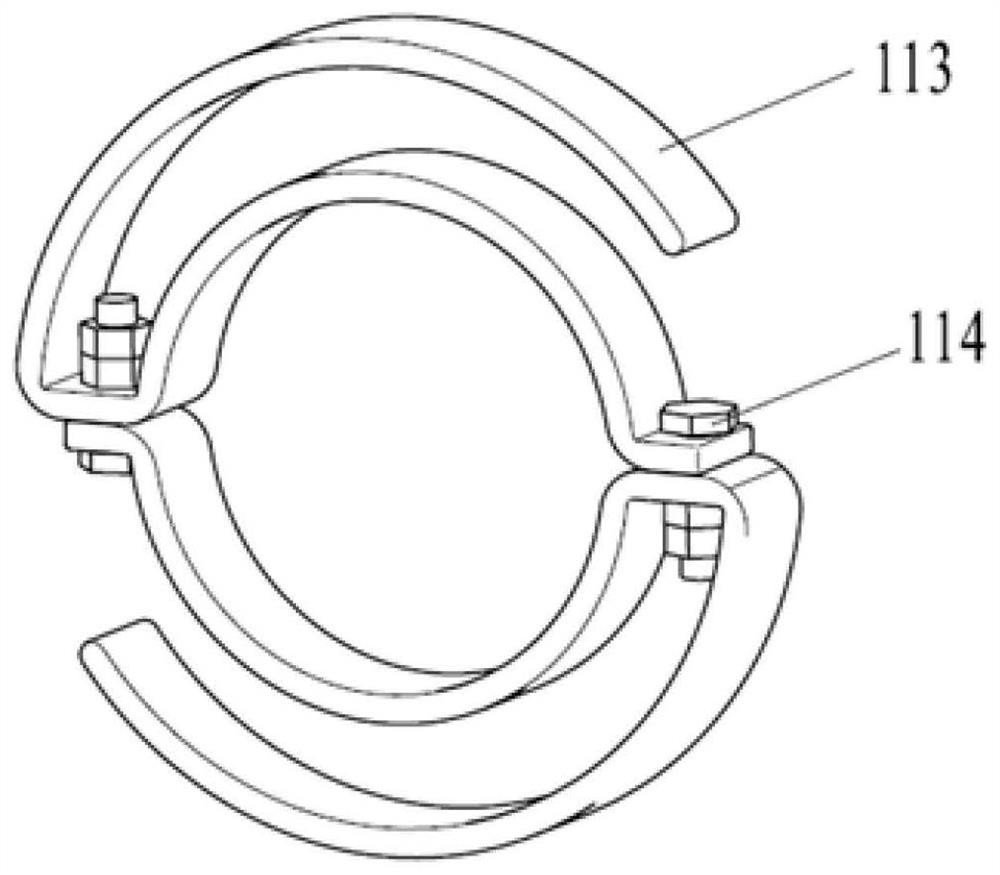

[0064] The "back-shaped bending" structure of this embodiment is as follows: image 3 As shown, it is made up of 4 semi-arc supports 113, wherein the semi-arc supports 113 form a support assembly in pairs, and the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com