Semiconductor thin film preparation device and preparation method

A thin-film preparation and semiconductor technology, which is applied to the semiconductor thin-film preparation device and the preparation field, can solve problems such as thin film thickness, and achieve the effects of saving energy, speeding up deposition and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

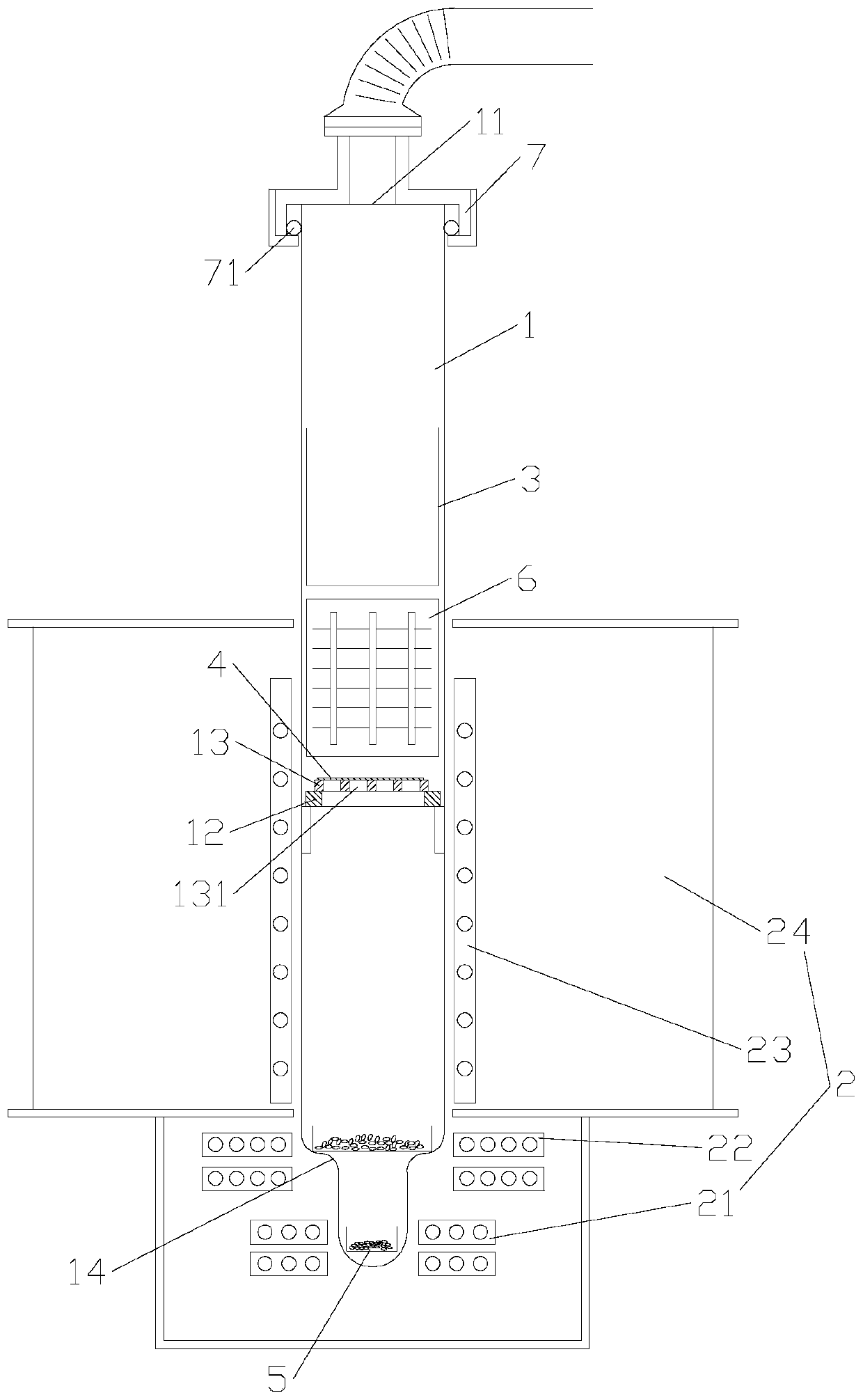

[0076] Embodiment 1: with ZnTe 1-x o x Taking the development of a thermoelectric thin film as an example, the preparation method of the above-mentioned semiconductor thin film is described as follows.

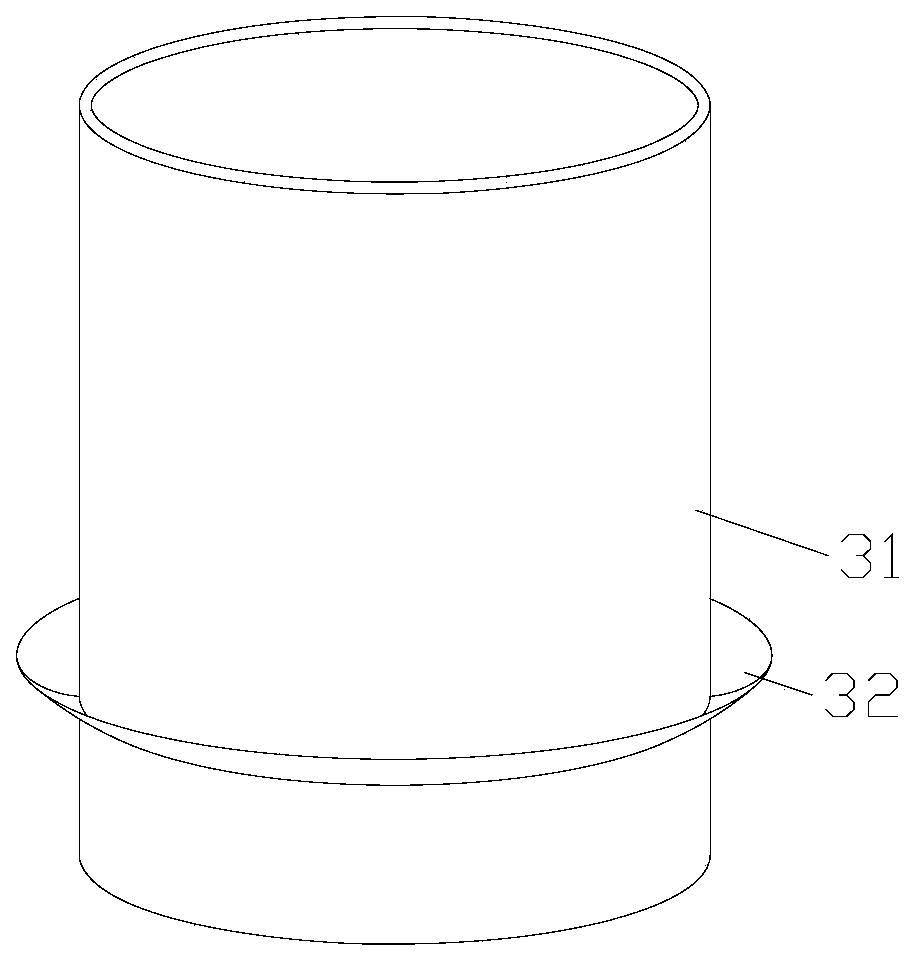

[0077] Take by weighing ZnTe (purity 99.99%) powder 10g (component A) and be placed in the evaporation source device 5 that is positioned at stepped hole 14 places, take by weighing ZnO (purity 99.995%) powder 2g (component B) be placed in furnace In the evaporation source device 5 at the bottom of the body 1, the above-mentioned evaporation source device 5, the annular structure 12, the shelf 13, the substrate 4, the heat preservation device 6 and the voltage stabilizing device 3 are sequentially put into the furnace body 1, and then the furnace The opening 11 at the upper end of the body 1 is tightly sealed by the air cover and the rubber ring 71; then start the vacuum pump to vacuum the system to 3X10 -2 The temperature can be heated up below the Pa, and the temperature c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com