Method and equipment for drying day lily degradation chlorophyll

A technology of drying equipment and drying method, which is applied in the direction of dryers for static materials, drying solid materials, drying chambers/containers, etc. It can solve the problems that the drying speed of materials is not easy to control, etc., and achieves convenient blanching and greening treatment, reasonable design, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

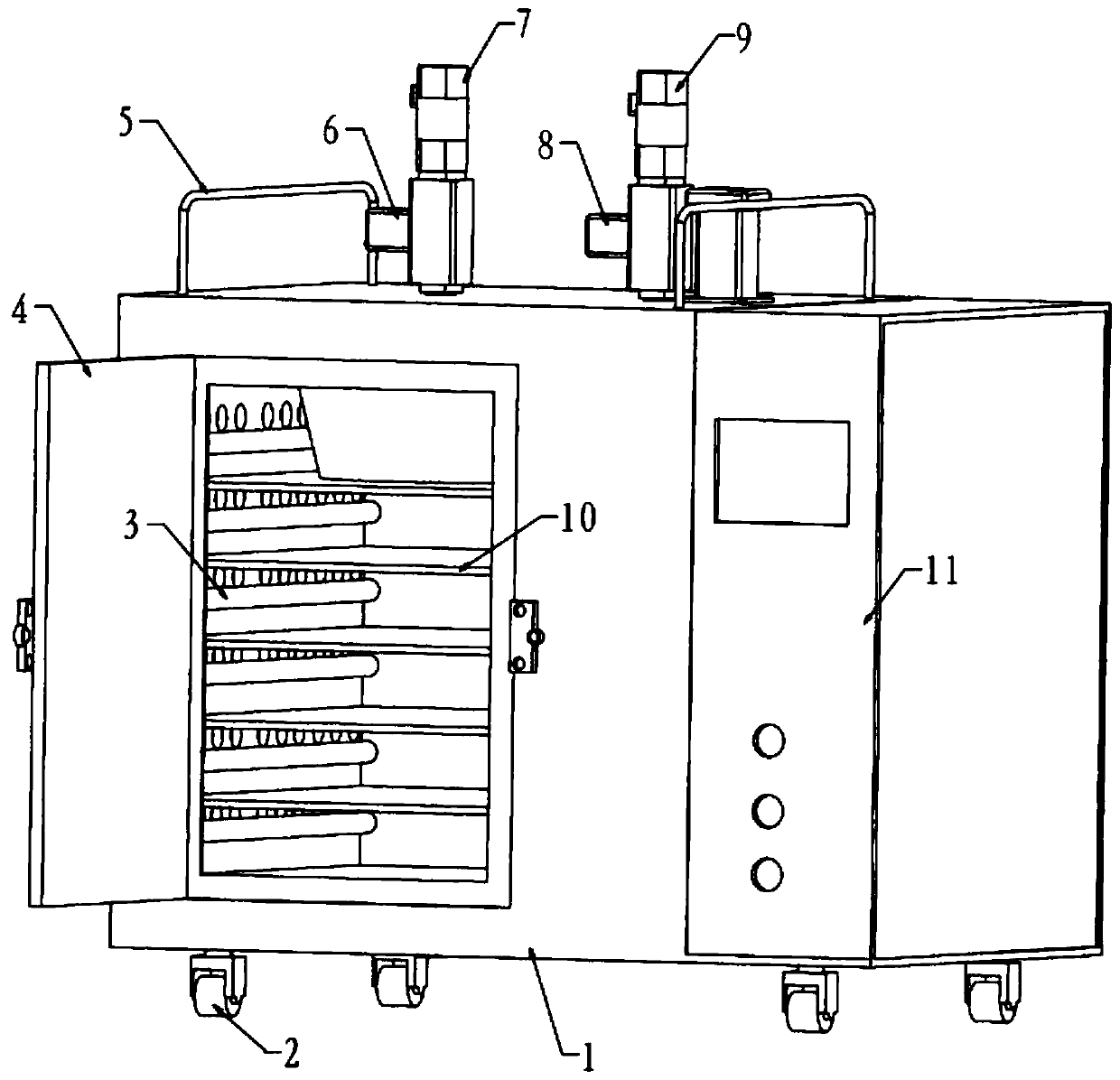

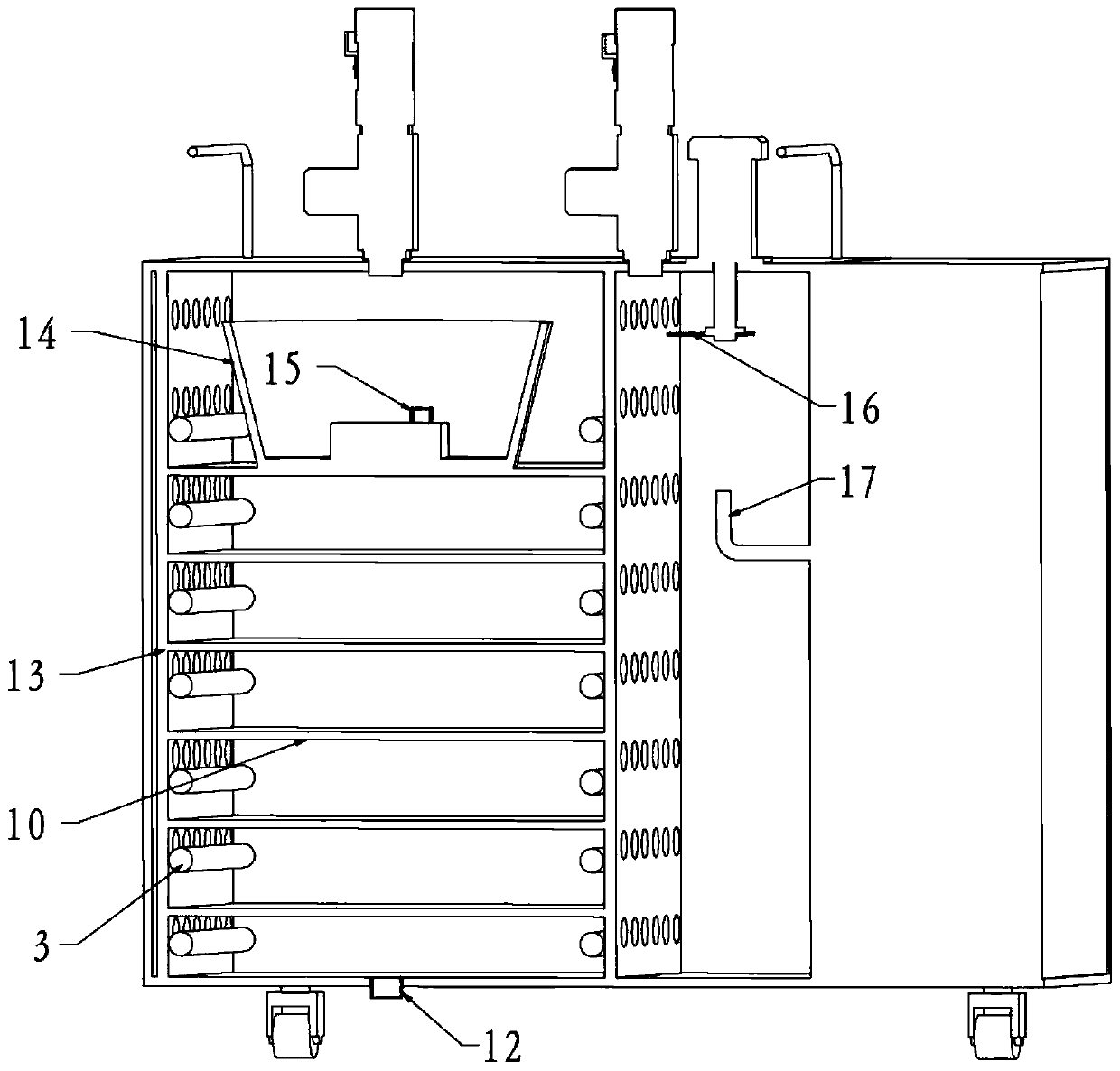

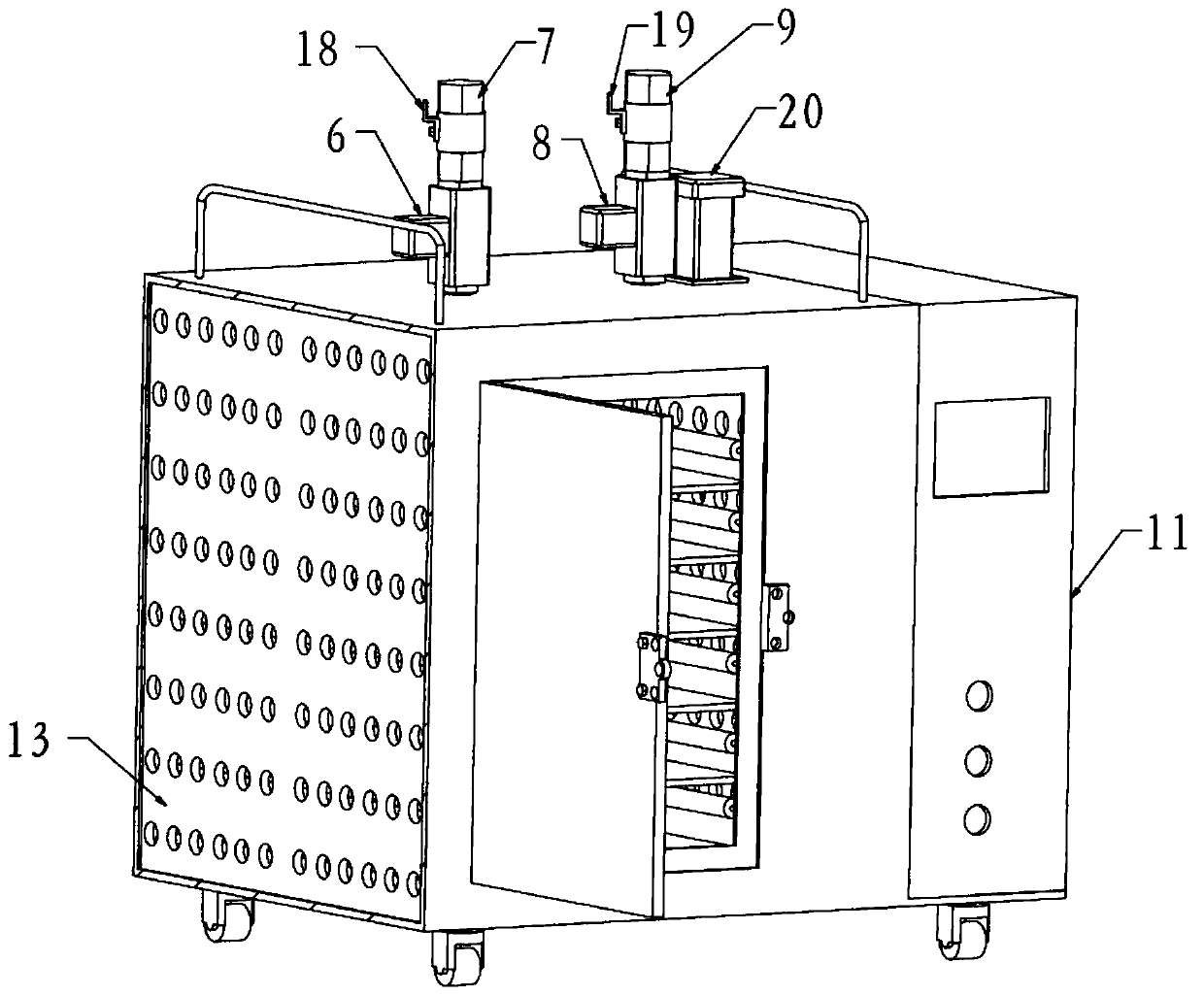

[0029] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

[0030] like Figure 1-Figure 3 Shown, the concrete structure of the present invention is: a kind of drying method of day lily degrading chlorophyll, it comprises following preparation steps:

[0031] Step A. Turn on the power of the drying equipment. After the equipment starts stably, set the maximum temperature in the cabinet 1 to 80°C and the maximum humidity to 100%. Turn on the switches of the heating tube 17 and the infrared light tube 3 to heat the drying equipment to 80°C. ℃, the ultrasonic fog head 15 starts, the ultrasonic wave atomizes the water in the water basin 14, the humidity gradually ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com