Flexible pc graphene coated electromagnetic shielding film material and preparation method thereof

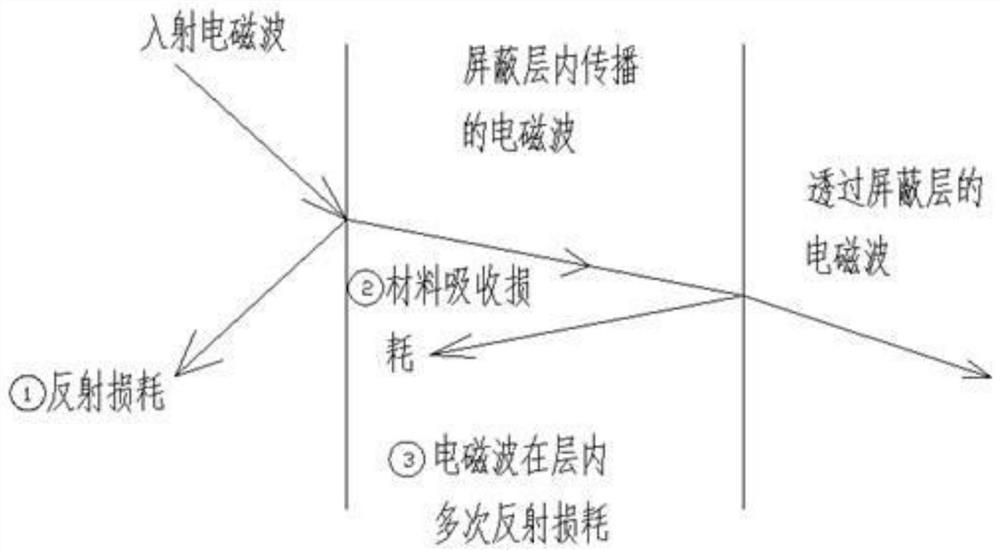

An electromagnetic shielding film, graphene technology, applied in conductive coatings, anti-corrosion coatings, coatings, etc., can solve the problems of difficult surface resistance of conductive coatings, difficult to form conductive paths, multiple reflection losses, etc., to achieve excellent shielding efficiency, enhanced Adhesion strength, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

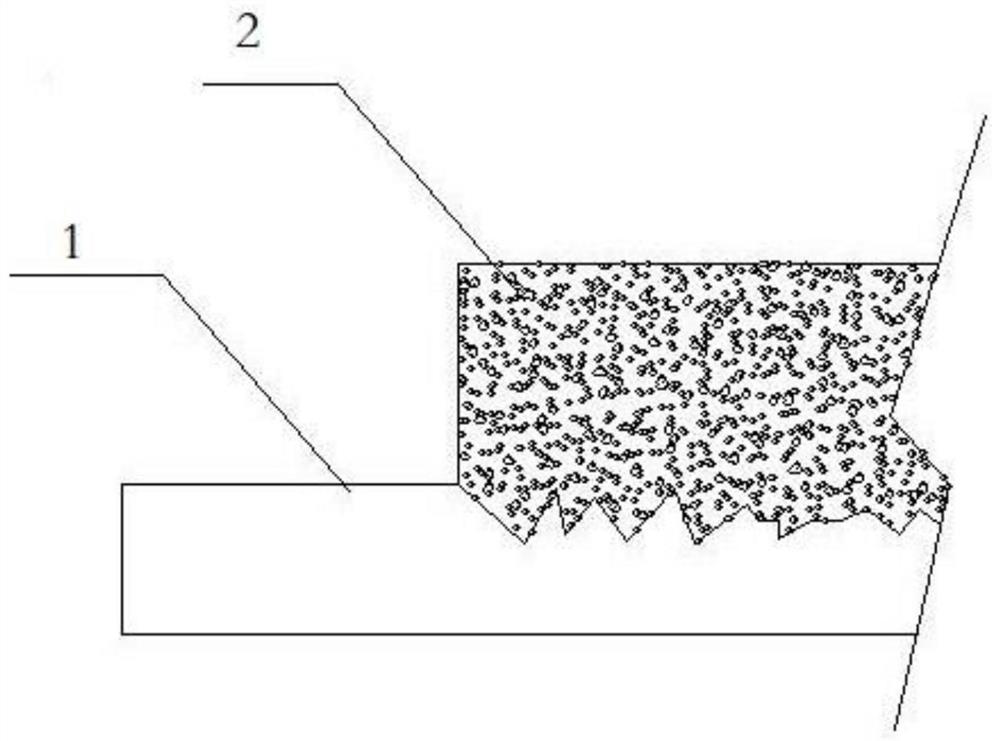

Method used

Image

Examples

Embodiment 1

[0061] A kind of preparation method of flexible PC graphene coating electromagnetic shielding film material, comprises the following steps:

[0062] (1) Firstly, wipe the PC film after 0.02mm clean, and then through appropriate corona treatment, the surface of the film will form small pores, reaching a certain roughness, and increasing the adhesion strength of the subsequent graphene-coated film;

[0063] (2) Add water-based acrylic resin, graphene slurry, defoamer, and leveling agent with a mass ratio of 1:0.55:0.004:0.045 into the vacuum mixer in sequence, adjust the negative pressure to -0.04mpa, and the speed to 1200r / min, and the stirring time is 3 hours; the solvent water in the graphene slurry is better compatible with the water-based acrylic resin, and the graphene and water-based acrylic resin are evenly dispersed under the action of the high-speed shear stirring paddle;

[0064] The graphene slurry includes graphene, water and a dispersant, and the mass ratio of the...

Embodiment 2

[0070] A kind of preparation method of flexible PC graphene coating electromagnetic shielding film material, comprises the following steps:

[0071] (1) Firstly wipe clean the PC film with a thickness of 0.4 mm, and then undergo appropriate corona treatment to form small pores on the surface of the film to reach a certain roughness and increase the adhesion strength of the subsequent graphene-coated film;

[0072] (2) Add water-based acrylic resin, graphene slurry, defoamer, and leveling agent with a mass ratio of 1:0.65:0.006:0.055 into the vacuum mixer in sequence, adjust the negative pressure to -0.06mpa, and the speed to 1800r / min, and the stirring time is 6 hours; the solvent water in the graphene slurry is better compatible with the water-based acrylic resin, and the graphene and water-based acrylic resin are evenly dispersed under the action of the high-speed shear stirring paddle;

[0073] The graphene slurry includes graphene, water and a dispersant, and the mass rat...

Embodiment 3

[0079] A kind of preparation method of flexible PC graphene coating electromagnetic shielding film material, comprises the following steps:

[0080] (1) Firstly wipe clean the 0.2mm thick PC film, and then undergo appropriate corona treatment, the surface of the film will form tiny holes to reach a certain roughness, and increase the adhesion strength of the subsequent graphene-coated film;

[0081] (2) Add water-based acrylic resin, graphene slurry, defoamer, and leveling agent with a mass ratio of 1:0.6:0.005:0.05 into the vacuum mixer in sequence (weigh 10g of water-based acrylic resin, 6g Graphene slurry, 0.05g of defoamer, 0.5g of GSK-550 polyether modified siloxane leveling agent are added to the vacuum mixer successively), and the negative pressure is adjusted to be -0.05mpa, and the rotating speed is 1600r / min , the stirring time is 4h; the solvent water in the graphene slurry is better compatible with the water-based acrylic resin, and the graphene and the water-based...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com