Multi-equipment process scheduling method for process sequence time selection

A process scheduling, multi-equipment technology, applied in data processing applications, instruments, calculations, etc., can solve problems such as poor parallelism of parallel processes, long idle waiting time for equipment, and parallel processing of parallel processes is not considered, so as to facilitate calculation, increase Parallelism, the effect of reducing the total time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

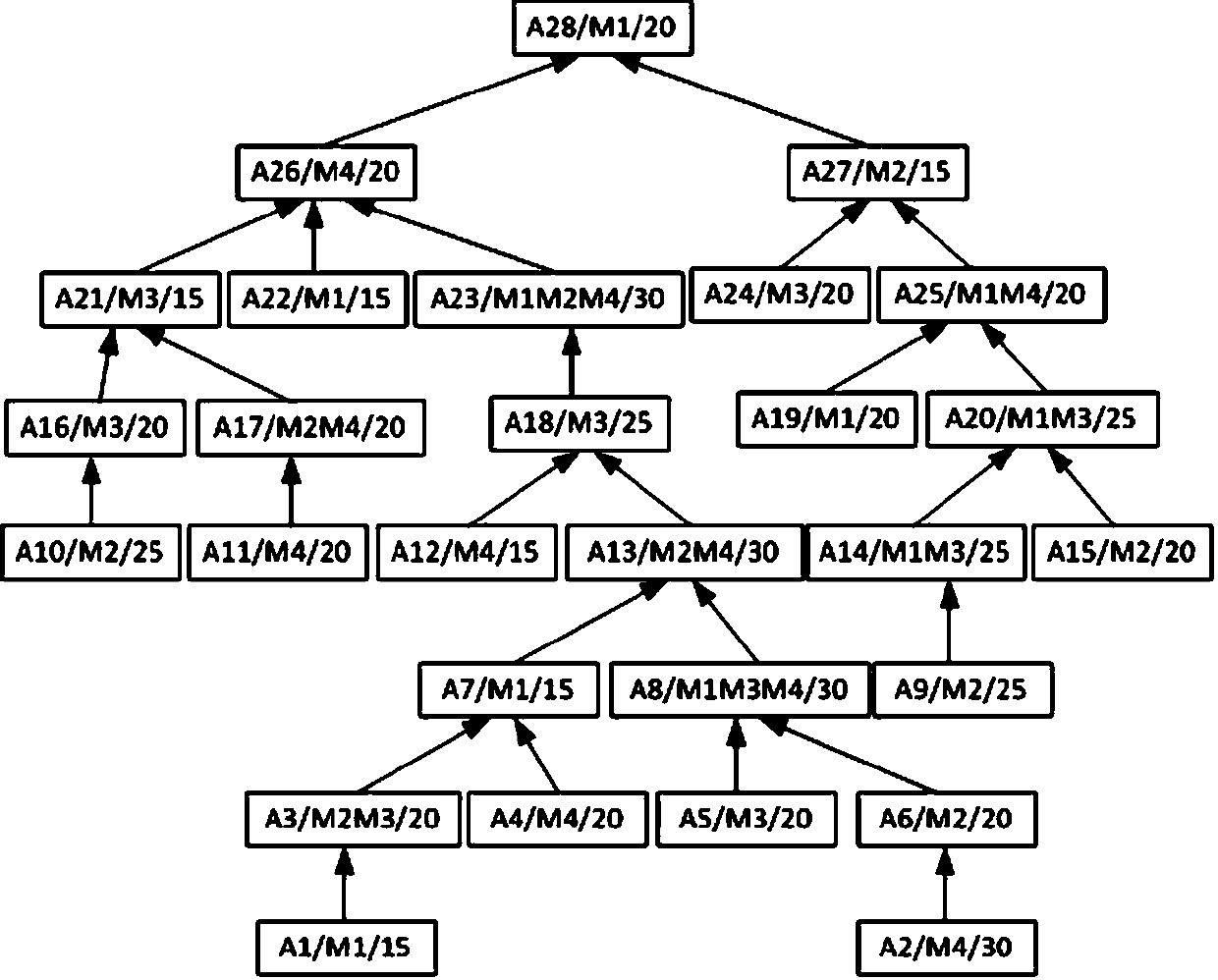

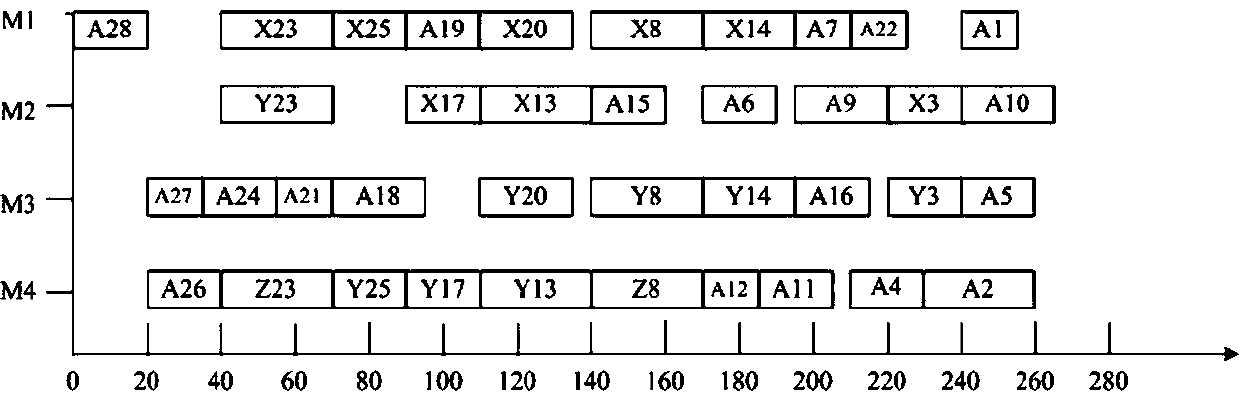

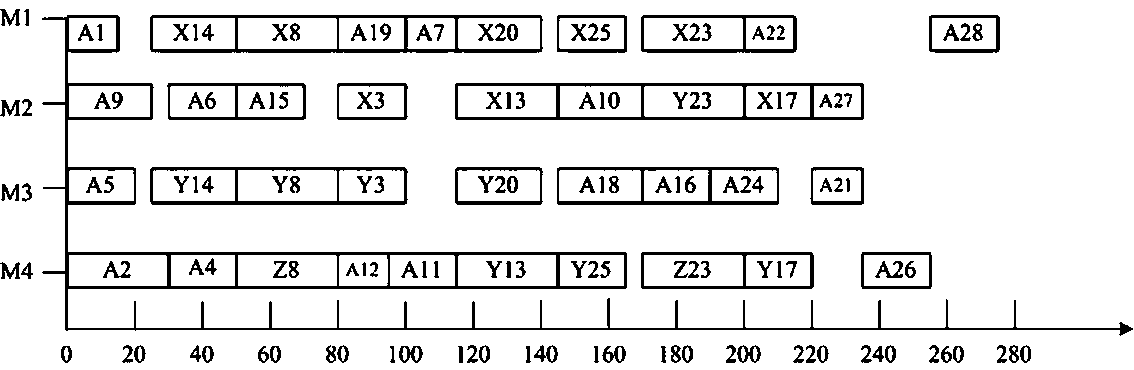

[0054] This embodiment provides a multi-equipment process scheduling method for process sequence timing, which inverts the partial order relationship of the processing processes in the processing process tree with multiple equipment processes to obtain a reverse-order processing process tree, and then determines the process tree in the product processing process. The processing sequence of each process; set the process queue, and store the processing sequence of each process in the product processing tree into the process queue; the process queue has multiple sub-processes, and the process on the first sub-process sequence is removed from the process queue Dequeue and schedule in the queue to form an initial scheduling plan; dequeue other processes in the process queue in turn, and judge whether it is a common process or a multi-equipment process. The timing adjustment strategy determines its scheduling plan. If the dequeuing process is a multi-equipment process, the multi-equi...

Embodiment 2

[0056] refer to Figure 1 to Figure 3 , a multi-equipment process scheduling method for process sequence timing provided by the present invention, inverts the partial order relationship of the processing processes in the processing process tree with multiple equipment processes, obtains the reverse order processing process tree, and then determines the product processing process tree The processing sequence of each process; set the process queue, and store the processing sequence of each process in the product processing tree into the process queue; the process queue has multiple sub-processes, and the process on the first sub-process sequence is removed from the process queue Dequeue and schedule in the queue to form an initial scheduling plan; dequeue other processes in the process queue in turn, and judge whether it is a common process or a multi-equipment process. The timing adjustment strategy determines its scheduling plan. If the dequeuing process is a multi-equipment p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com