Terminal device power supply system, method, chip and terminal device

A technology for power supply system and terminal equipment, applied in load supply circuits, current collectors, electric vehicles, etc., can solve problems such as reducing the stability of terminal equipment, reducing the output voltage of the battery, and increasing the internal resistance of the battery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

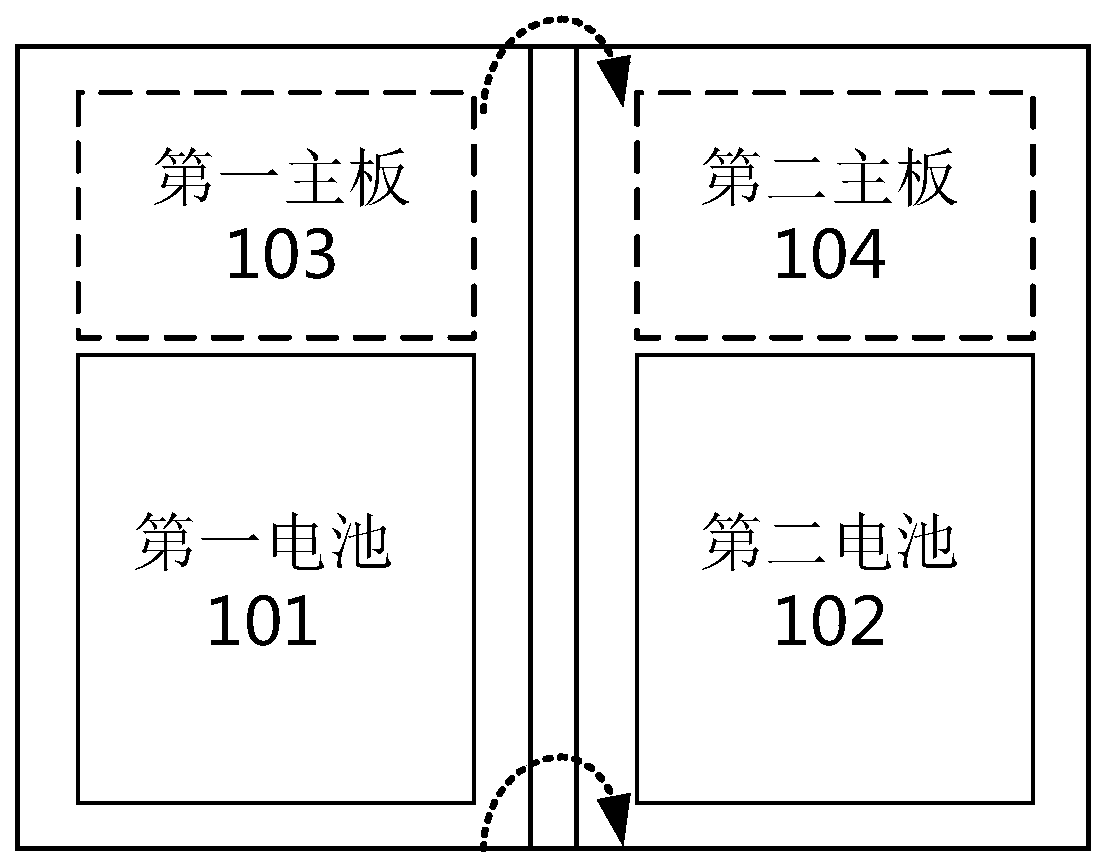

[0130] see Figure 5 , which is a schematic diagram of a power supply system for a terminal device provided in an embodiment of the present application.

[0131] The power supply system of the terminal device provided in the embodiment of the present application includes: a battery pack 601 , a bypass circuit 602 , a step-down circuit 603 , a controller 604 and a power consumption element 605 .

[0132] see Figure 6 , which is a circuit diagram of the power supply system provided by the embodiment of the present application.

[0133] The output end of the battery pack 601 is connected to the input end of the step-down circuit 603, the output end of the step-down circuit 603 is connected to the power consumption element 605 of the terminal equipment, and the two ends of the bypass circuit 602 are connected across the input end and the output end of the step-down circuit 603. end.

[0134] The controller 604 is connected to the battery pack 601 , the bypass circuit 602 and t...

Embodiment 2

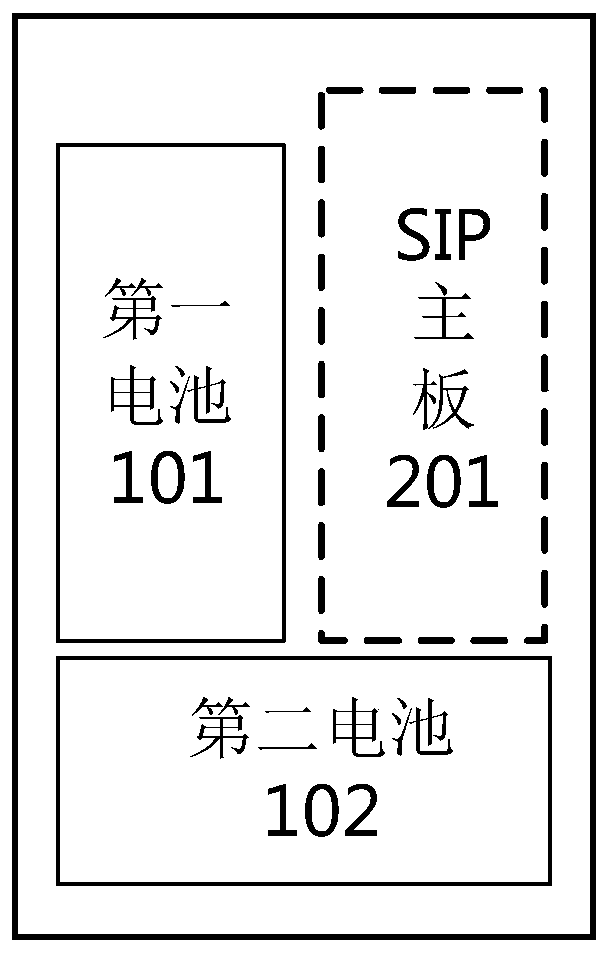

[0148] see Figure 7 , which is a schematic diagram of another power supply system of a terminal device provided in an embodiment of the present application.

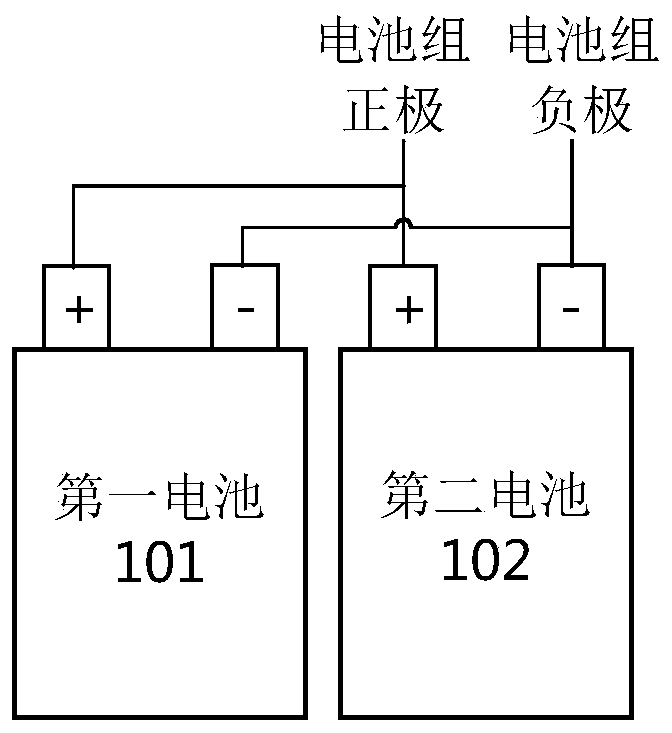

[0149] The battery pack 601 of the power supply system includes at least the following two batteries: a first battery 601a and a second battery 601b. The output voltage of the first battery 601a is V1, and the output voltage of the second battery 601b is V2. The battery pack 601 further includes: a first switch tube Q1 , a second switch tube Q2 and a third switch tube Q3 .

[0150]The positive pole of the first battery 601a is connected to the input terminal of the step-down circuit 603, the negative pole of the first battery 601a is connected to the positive pole of the second battery 601b through the second switching tube Q2, and the negative pole of the second battery 601b is grounded.

[0151] One end of the first switching tube Q1 is connected to the negative pole of the first battery 601a, and the other end is g...

Embodiment 3

[0241] Continue to see Figure 7 , when the controller determines that the first battery 601a and the second battery 601b need to be switched to the parallel mode, it controls the second switch tube Q2 to be turned off, and controls the first switch tube Q1 and the third switch tube Q3 to be turned on.

[0242] For the various ways in which the controller determines that the batteries in the battery pack 601 need to be switched from the series mode to the parallel mode, refer to the relevant description in Embodiment 2, and details will not be repeated here in this embodiment. The working principle of the controller controlling the switching of the battery pack from the series mode to the parallel mode will be described in detail below.

[0243] see Figure 18 , which is a control timing diagram for switching from the series mode to the parallel mode provided by the embodiment of the present application.

[0244] When the controller controls the battery to switch from the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com