Master-slave trolley capable of quickly turning over goods

A technology of sub-trolley and trolley, which is applied in the field of sub-trolley and mother-trolley, can solve problems such as unreasonable structural design, difficult installation and separation of sub-trolley and parent trolley, poor flexibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment example 1

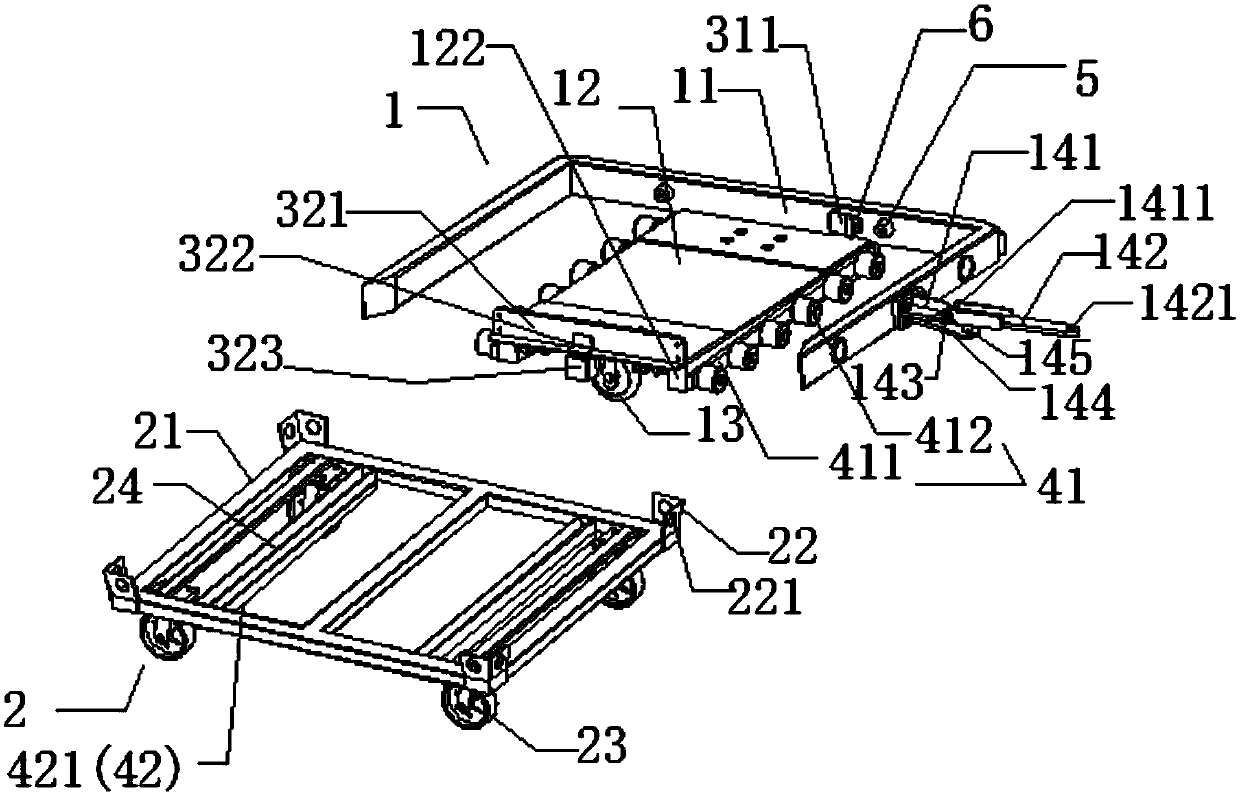

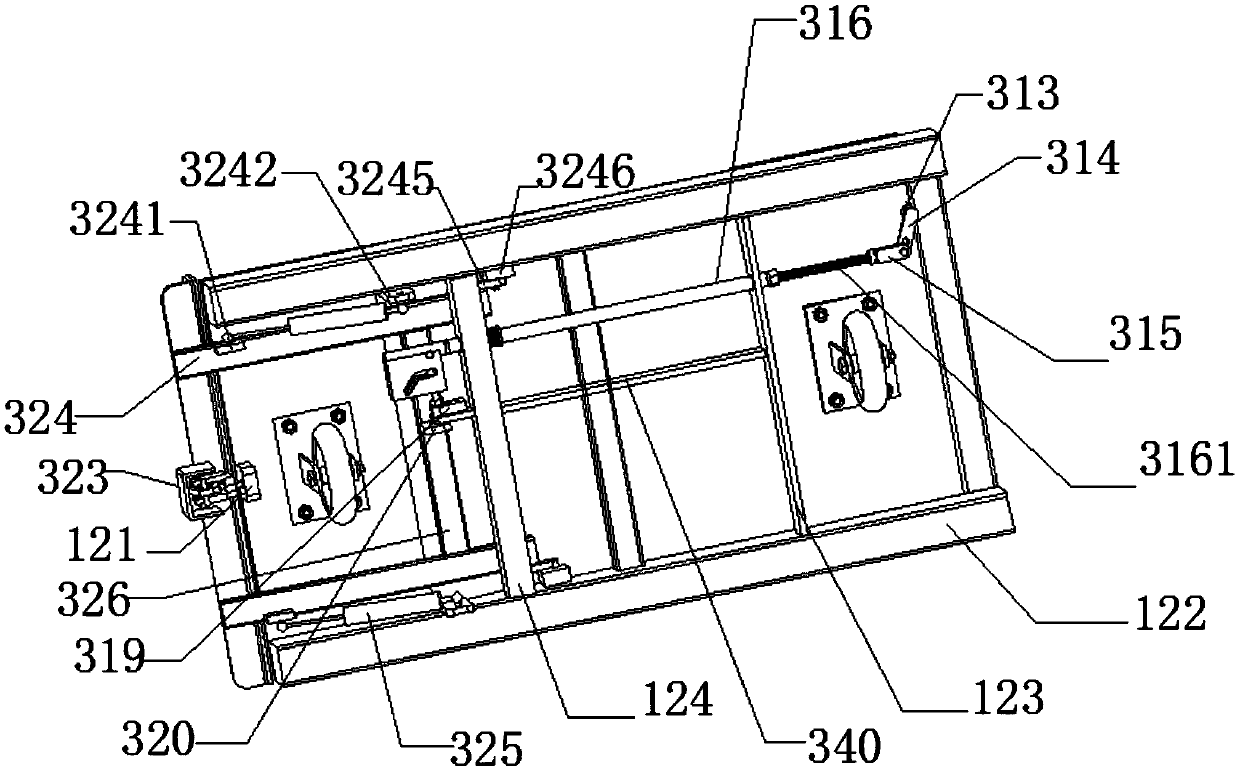

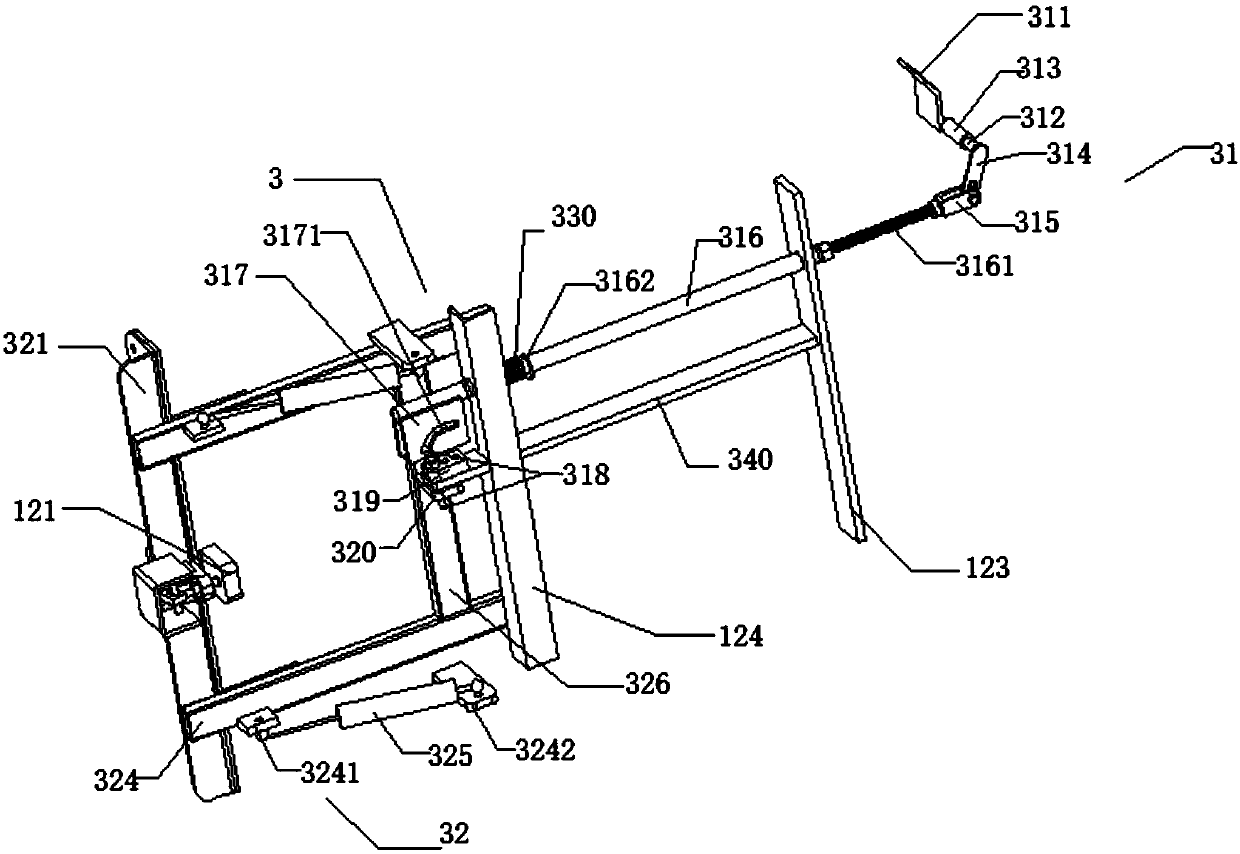

[0042]A kind of sub-mother trolley that can quickly turn over goods, comprising: a mother trolley body 1 (the existing mother trolley body 1 in the prior art can be used), a sub-trolley 2 (the existing one in the prior art can be used) Child trolley 2), mother trolley body 1 comprises U-shaped mother frame 11, the mother trolley bearing plate 12 that is screwed or welded to the inner side of the middle vertical plate surface of U-shaped mother frame 11, is installed on the mother trolley The load plate 12 is close to the two rollers 13 on the bottom surface of the load plate 12 of the mother trolley near the two ends of the length, and the draw bar 14 that is screwed vertically to the front side plate surface in the U-shaped mother frame 11, and the draw bar 14 includes a screw fixed on the U The connecting sheet metal 141, rotating sheet metal 142, and pin shaft 143 of the front side plate in the shape mother frame 11, the front end of the connecting sheet metal 141 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com