A method for extracting polypeptide components in wood frog eggs

A technology of wood frog eggs and egg membranes, which is applied in the field of preparation of polypeptide components, can solve the problems of limiting the commercialization of large-scale extraction of polypeptides, high price, and large amount of enzymes, and achieves the preservation of antioxidant activity, convenient operation, and short production cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

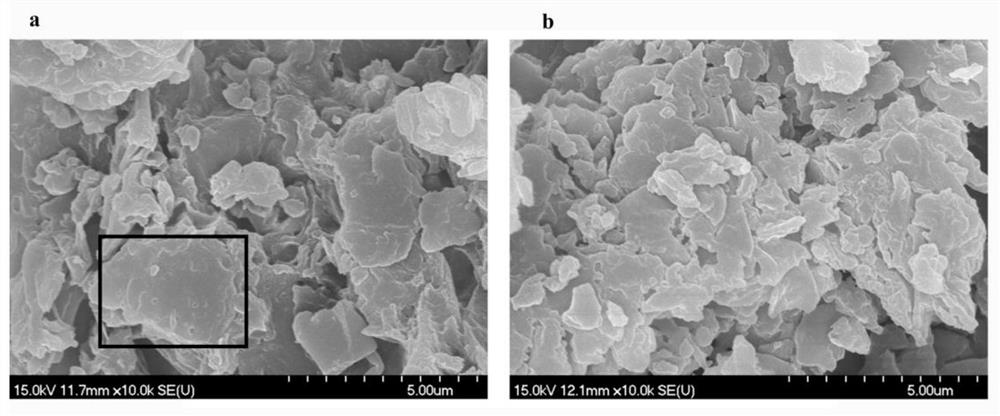

[0037] Step 1) Mix 10.0g wood frog eggs with 20% sodium chloride, add 30 medium-sized ball milling beads with a particle diameter of 10mm, and ball mill for 30min at 100rpm, such as figure 1 Shown, the scanning electron microscope (SEM) of wood frog ovum powder ball milling (a) and after ball milling (b), after ball milling, the egg membrane and egg nucleus of wood frog ovum become a homogeneous body;

[0038] Step 2) Using ethanol as the extractant with a solid-to-liquid ratio of 1:10, extracting with 300W microwave at 40°C for 40 minutes to obtain the crude extract of Rana egg protein peptide; rotary evaporation to remove the ethanol in the solvent;

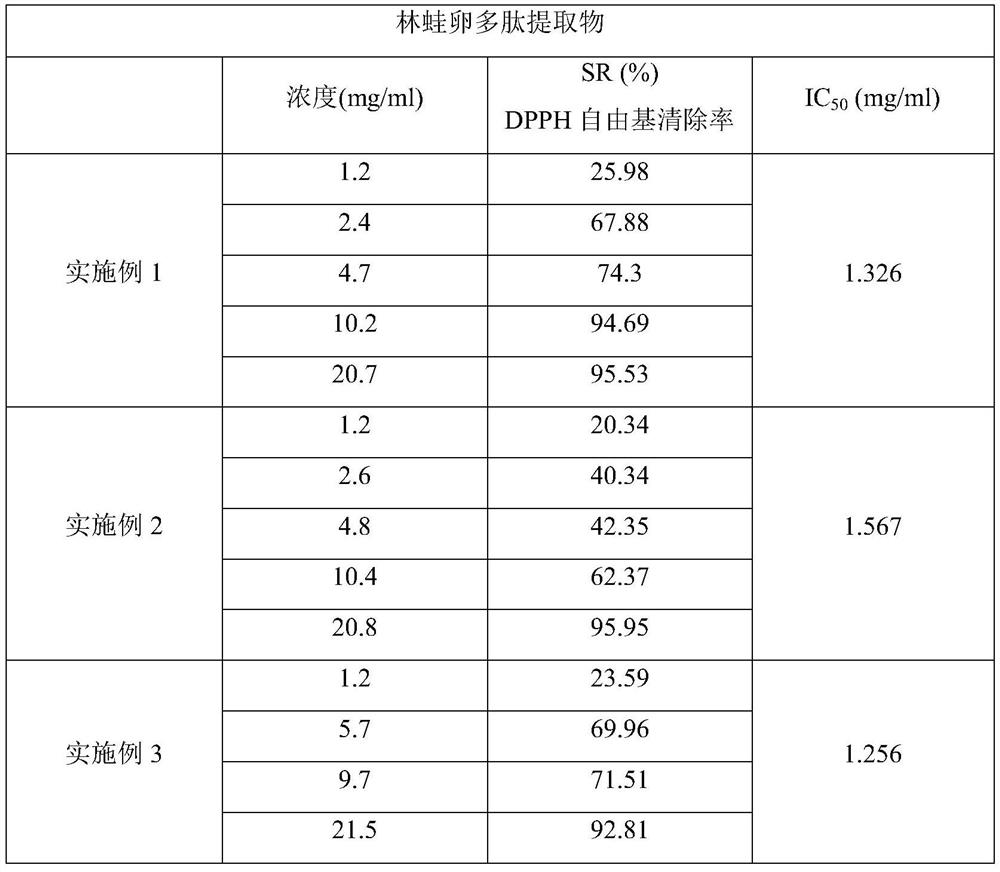

[0039] Step 3) Add 10000U / g papain, the amount of enzyme added is 1.0%, enzymolyze at 55°C for 60min, and use 1mol / L NaOH solution to maintain a constant pH value of 7.0, heat in a boiling water bath for 10min to inactivate the enzyme, after inactivating the enzyme The enzymatic hydrolysis solution was centrifuged at 10000rpm f...

Embodiment 2

[0041] Step 1) Mix 10.0g wood frog eggs with 40% sodium hydroxide, add 30 medium-sized ball milling beads with a particle diameter of 10mm, and ball mill for 30min at 100rpm, so that the egg membrane and egg nucleus of the wood frog eggs become homogeneous One;

[0042] Step 2) Use ethanol as the extractant, the ratio of solid to liquid is 1:10, and extract with 400W microwave for 30min to obtain the crude extract of Rana egg protein peptide; spin evaporate to remove the alcohol in the solvent, add 10040U / g neutral protease, the amount of enzyme added 1.0%, enzymatic hydrolysis at 55°C for 60 minutes, and use 1mol / L NaOH solution to maintain a constant pH value of 7.0;

[0043] Step 3) Heat in a boiling water bath to inactivate the enzyme for 10 minutes, centrifuge the enzymolyzed solution at 10,000 rpm for 15 minutes after inactivating the enzyme, and precipitate and freeze-dry to obtain the antioxidant active polypeptide. The protein content of the antioxidant active polypep...

Embodiment 3

[0045] Step 1) Mix 10.0 g of wood frog eggs with 80% sodium bicarbonate, add 30 medium-sized ball milling beads with a particle diameter of 10 mm, and ball mill for 1 hour at 100 rpm, so that the egg membrane and nucleus of the wood frog eggs become homogeneous One;

[0046] Step 2) Use ethanol as the extractant, the ratio of solid to liquid is 1:15, microwave extraction at 40°C for 40 minutes to obtain the crude extract of Rana egg protein peptide; spin evaporate to remove the alcohol in the solvent, add alkaline protease, and add the amount of enzyme 1.0%, enzymatic hydrolysis at 55°C for 60 minutes, and use 1mol / L NaOH solution to maintain a constant pH value of 7.0;

[0047] Step 3) Then heat in a boiling water bath to inactivate the enzyme for 10 minutes, centrifuge the enzymolyzed solution at 10,000 rpm for 15 minutes after inactivating the enzyme, and precipitate and freeze-dry to obtain the antioxidant active polypeptide. The clearance rate reached 93.37%, and the hal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com