A method for producing low carbon steel and ultra low carbon steel molten steel temperature and cleanliness control method

A technology for ultra-low carbon steel and molten steel temperature, which is applied in the field of temperature and cleanliness control of molten steel in the production of low-carbon steel and ultra-low carbon steel. It can solve problems such as insufficient tapping temperature and excessive temperature drop, and achieve improved Cleanliness, reducing slag oxidation, and realizing the effect of slag modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Take the production of DC01 steel with a converter-RH-continuous casting process, and a converter with a capacity of 120t as an example.

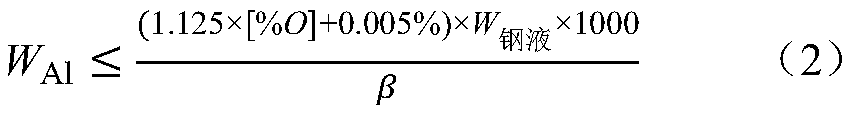

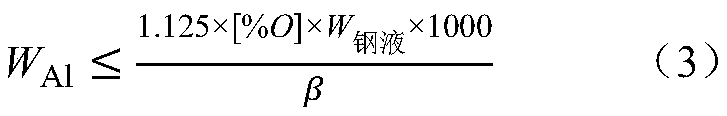

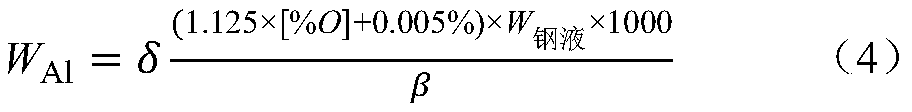

[0034] The converter tapping temperature is 1645°C, and the converter tapping [%O] is 600×10 -6 , the average temperature drop in the converter-RH process is 55°C, and the calculated RH entry temperature is 1590°C. In actual production, the RH entry temperature is required to be above 1610°C. In order to meet the temperature requirements of the molten steel in the subsequent process, it is necessary to add aluminum to the molten steel in the ladle or during the tapping process before tapping the converter and raise the temperature by at least 20°C. Add 94.0kg of total aluminum to the molten steel according to the temperature rise, nitrogen content of molten steel and slag modification control requirements, the reaction of aluminum and oxygen makes the temperature rise effect of the molten steel is 23.3°C, and the aluminum content in ...

Embodiment 2

[0036]Take the production of IF steel with a converter-RH-continuous casting process and a converter with a capacity of 120t as an example.

[0037] The converter tapping temperature is 1665°C, and the converter tapping [%O] is 500×10 -6 , the average temperature drop of the converter-RH process is 60°C, and the calculated RH entry temperature is 1605°C. In actual production, the RH entry temperature is required to be above 1620°C. In order to meet the temperature requirements of the molten steel in the subsequent process, it is necessary to add aluminum to the molten steel in the ladle or during the tapping process before tapping the converter and raise the temperature by at least 15°C. According to the heating temperature and nitrogen content control requirements, it is determined to add 77.0kg of total aluminum to the molten steel. The reaction of aluminum and oxygen makes the temperature of the molten steel rise to 19.1°C. The aluminum content in the molten steel after tap...

Embodiment 3

[0039] Take the converter-RH-continuous casting process to produce DC04 steel with a converter capacity of 150t as an example.

[0040] The converter tapping temperature is 1659°C, and the converter tapping [%O] is 650×10 -6 , the average temperature drop of the converter-RH process is 65°C, and the calculated RH entry temperature is 1594°C. In actual production, the temperature of RH entering the station is required to be above 1615°C. In order to meet the temperature requirements of the molten steel in the subsequent process, it is necessary to add aluminum to the molten steel in the ladle or during the tapping process before tapping the converter to raise the temperature to at least 21°C. According to the heating temperature and nitrogen content and the slag modification control requirements, it is determined to add 124.4kg of total aluminum to the molten steel. The reaction of aluminum and oxygen makes the temperature of the molten steel rise to 24.7°C. The aluminum conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com