Method for reinforcing concrete structure with prestressed FRP batten embedded at end

A concrete structure and prestressing technology, used in bridge reinforcement, bridge erection/assembly, bridge maintenance, etc., can solve problems such as increased construction workload and structural damage, achieve good reinforcement effect, small damage, and inhibit peeling damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

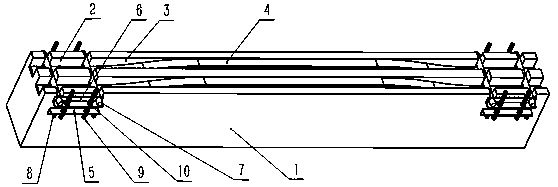

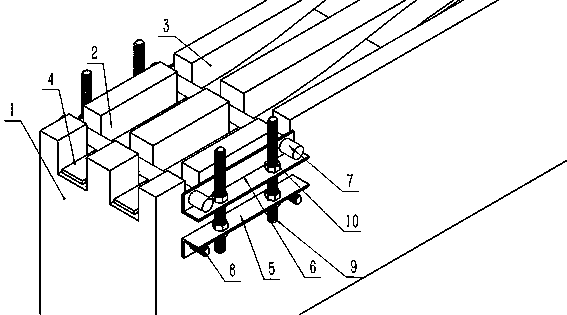

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

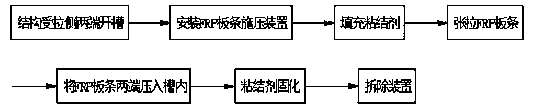

[0027] Such as Figure 1-6 Shown, the present invention is based on the concrete structure reinforcing method of end embedding prestressed FRP lath, and its steps are:

[0028] (1) Grooving;

[0029] Take the concrete structure to be reinforced as the beam 1 to be reinforced as an example. A slotting machine is used to symmetrically open several end slots 2 along the center line at predetermined positions at both ends of the tension side of the beam 1 to be reinforced, and an inclined transition slot 3 is provided between the end slots 2 and the middle section of the beam 1 to be reinforced. , using a grinding machine to grind the bottom of the transition groove 3 flat, wherein the distance, length and size of the end groove 2 and the transition groove 3 should be based on the size of the beam 1 to be strengthened, the stiffness of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com