High-pressure-resistant reverse needle valve

A needle valve, high pressure resistant technology, applied in valve details, valve device, parts contacting between valve elements and valve seat, etc., can solve the problem of limited service life extension, improve stability, excellent corrosion resistance, etc. performance, the effect of good anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

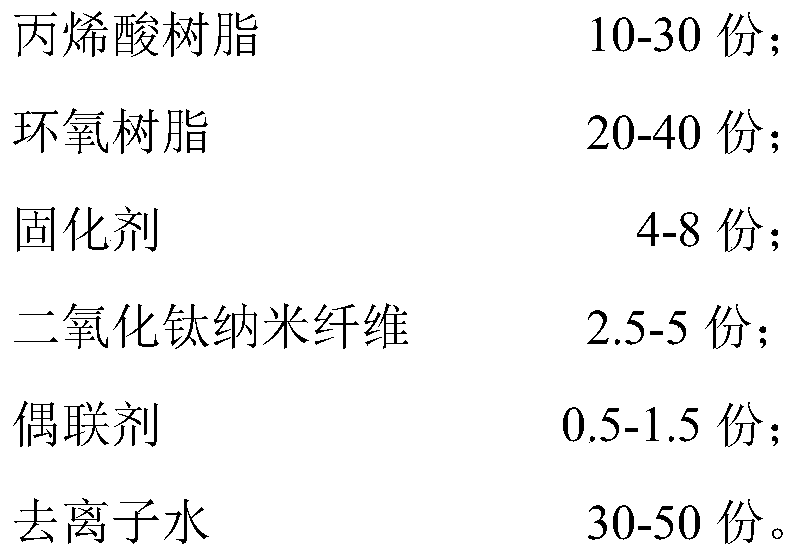

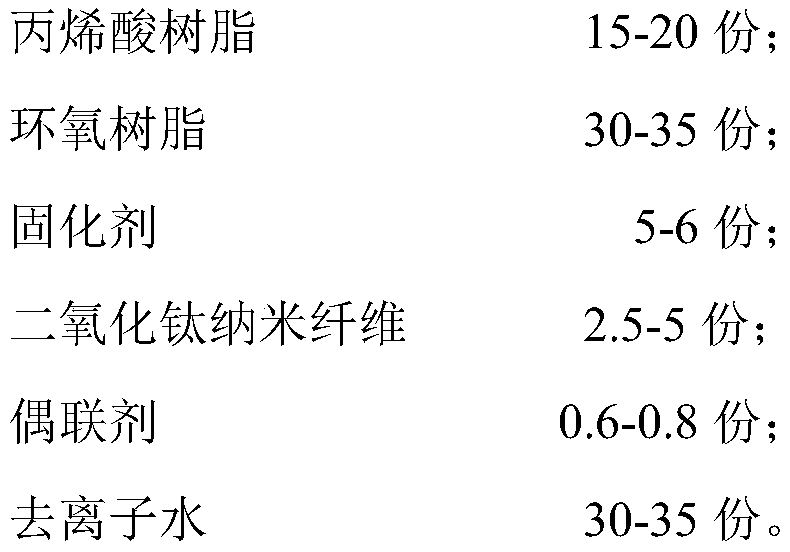

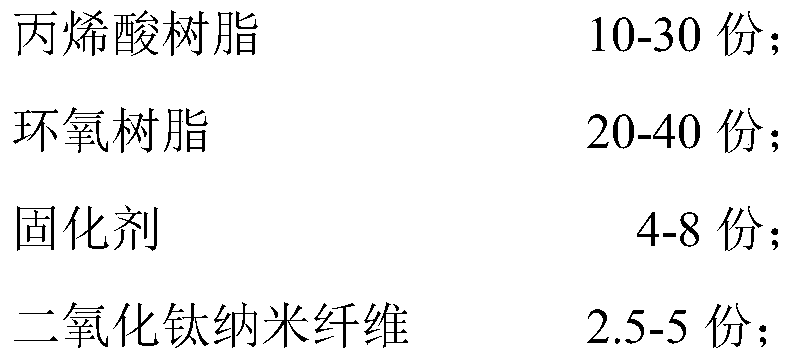

Method used

Image

Examples

Embodiment 1

[0039] A high-pressure resistant reverse needle valve includes a valve body, a valve core, an elastic member and a valve stem. Among them, the surface of the valve core, the elastic member and the valve stem are all coated with anti-corrosion coating, and the anti-corrosion coating raw materials include: 20 parts of acrylic resin, bisphenol A epoxy resin (E-44) 33 6 parts, 6 parts of phenalkamine curing agent (T-31), 5 parts of titanium dioxide nanofibers, 20 parts of zinc sulfate, 0.8 parts of coupling agent (KH-550), 6 parts of barium sulfate, 1.4 parts of silicon carbide, 35 parts of deionized water share. The weight ratio of titanium dioxide nanofibers and zinc sulfate is 1:4.

[0040] Wherein, the method for loading zinc sulfate on titanium dioxide nanofibers comprises the following steps:

[0041] S1, taking zinc sulfate and adding distilled water and stirring continuously until dissolved to obtain a saturated solution of zinc sulfate, which is transferred to the react...

Embodiment 2

[0050] A high-pressure resistant reverse needle valve includes a valve body, a valve core, an elastic member and a valve stem. Among them, the surface of the valve core, the elastic member and the valve stem are all coated with anti-corrosion coating, and the anti-corrosion coating raw materials include: 20 parts of acrylic resin, bisphenol A epoxy resin (E-44) 33 6 parts, 6 parts of phenalkamine curing agent (T-31), 5 parts of titanium dioxide nanofibers, 20 parts of zinc sulfate, 0.8 parts of coupling agent (KH-550), 6 parts of barium sulfate, 1.4 parts of silicon carbide, 35 parts of deionized water share.

[0051] The preparation method of anticorrosion coating comprises the following steps:

[0052] S1, mix epoxy resin, acrylic resin and deionized water with each other and stir thoroughly;

[0053] S2, add coupling agent, fully stir evenly;

[0054]S3, add barium sulfate, zinc sulfate, titanium dioxide nanofibers, silicon carbide, fully stir evenly;

[0055] S4, befor...

Embodiment 3

[0057] A high-pressure resistant reverse needle valve includes a valve body, a valve core, an elastic member and a valve stem. Among them, the surface of the valve core, the elastic member and the valve stem are all coated with anti-corrosion coating, and the anti-corrosion coating raw materials include: 20 parts of acrylic resin, bisphenol A epoxy resin (E-44) 33 6 parts, 6 parts of phenalkamine curing agent (T-31), 5 parts of titanium dioxide nanofibers, 0.8 parts of coupling agent (KH-550), 6 parts of barium sulfate, 1.4 parts of silicon carbide, and 35 parts of deionized water. The weight ratio of titanium dioxide nanofibers and zinc sulfate is 1:4.

[0058] The preparation method of anticorrosion coating comprises the following steps:

[0059] S1, mix epoxy resin, acrylic resin and deionized water with each other and stir thoroughly;

[0060] S2, add coupling agent, fully stir evenly;

[0061] S3, add barium sulfate, titanium dioxide nanofiber, silicon carbide, fully s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com