Novel plug-in steel cylinder wind power base

A wind power foundation and steel cylinder technology, applied in infrastructure engineering, construction, etc., can solve the problems of long construction period, high cost, and high project cost, and achieve the effects of easy construction, good wave resistance, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

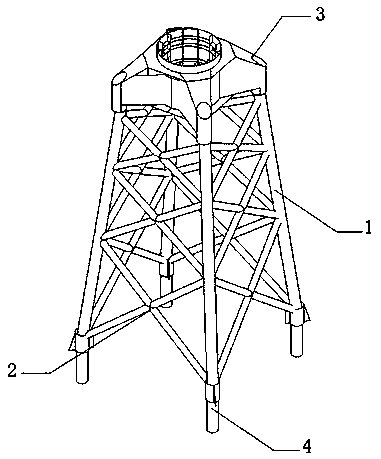

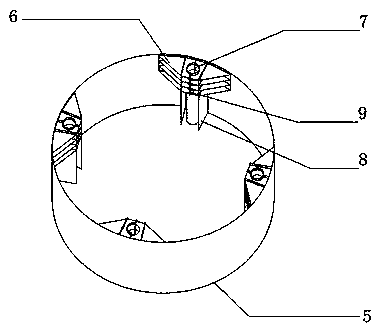

[0039] refer to figure 1 , figure 2 and Figure 4, the steel cylinder 5 is welded with reserved steel sleeves 7 at the four positions corresponding to the upper jacket structure leg piles 4, if the upper jacket is a three-pipe type, the reserved steel sleeves 7 and its adjacent parts will be correspondingly reduced , the reserved steel sleeve 7 and the upper jacket 1 are arranged at equal intervals along the circumference of the steel cylinder 5, the diameter of the reserved steel sleeve 7 is 2.0m-3.0m, and the space between the leg pile 4 and the reserved steel sleeve 7 It is connected by grouting, and the inclined plate at the end of the steel sleeve 7 is reserved for sealing to avoid clearing the hole. The length is 10m-45m, depending on the soft soil conditions. The reserved steel sleeve 7 is connected to the steel cylinder 5 through the short rib 9 located vertically downward, the short rib 9 is located in the middle of the reserved steel sleeve 7, and the upper end of...

Embodiment 2

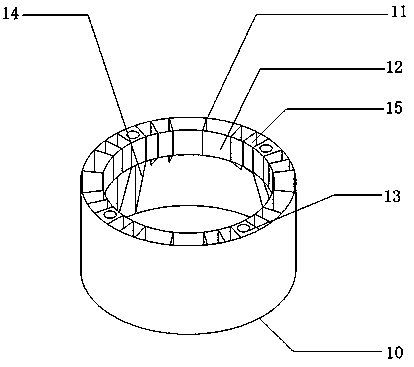

[0041] refer to figure 1 , image 3 with Figure 5 , the second steel cylinder 10 is welded with the second reserved steel sleeve 13 at the four positions corresponding to the upper jacket structure leg pile 4. If the upper jacket is of 3-pipe type, the reserved steel sleeve and its adjacent Parts are also reduced accordingly, the reserved steel sleeves and the upper jacket are arranged at equal intervals along the circular direction of the steel cylinder, the diameter of the second reserved steel sleeve 13 is 2m-3m, and the leg pile 4 and the second reserved steel sleeve The cylinders 13 are connected by grouting, and the end of the second reserved steel sleeve 13 is sealed with a slant plate to avoid hole cleaning. The second reserved steel sleeve 13 adopts a hole-shaped structure. The top and bottom of the second reserved steel sleeve 3 are welded with steel plates and welded with the inner cylinder 12. The length of the second reserved steel sleeve 13 can be 5m- 10m, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com