Non-bearing type light thin-wall damping partition wall

A non-load-bearing, lightweight technology, applied in the field of new wall materials, can solve the problems of poor durability, limited application, large thickness, etc., and achieve excellent seismic performance, good economic benefits, and thin thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

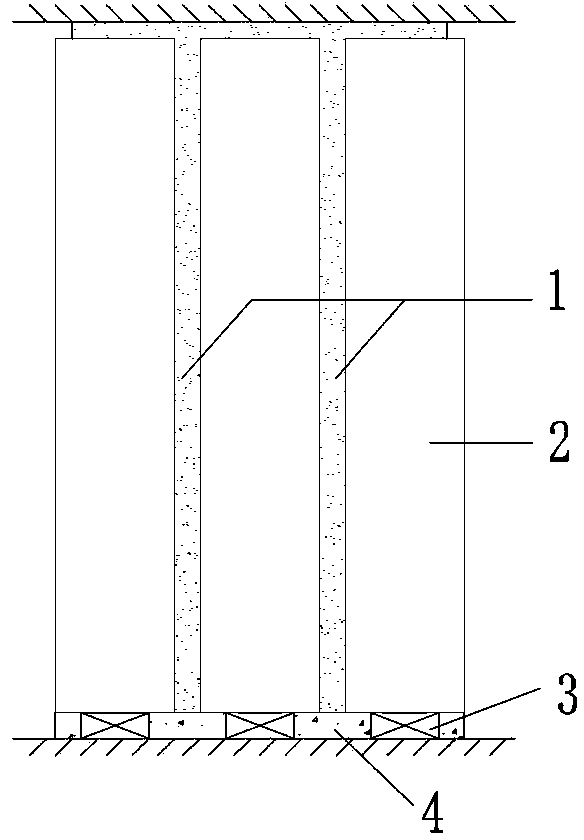

[0018] Embodiment 1, with reference to figure 1 .

[0019] The partition wall provided by the present invention includes a wallboard 2 made of ultra-high toughness cement-based composite material, the thickness of the wallboard is 10-20 mm, and the shape of the wallboard 2 in this embodiment is lath-shaped. Under the premise of meeting the requirements of the specification, the shape and thickness of the wallboard can also be flexibly designed with other shapes and thicknesses.

[0020] The mass ratio of the components of the mortar matrix of the ultra-high toughness cement-based composite material is cement: water: fine aggregate: fly ash: silica fume: granulated blast furnace slag: metakaolin = 1: (0.27~2.2): (0~ 3): (0~6.9): (0~0.3): (0~0.55): (0~0.4), where the maximum particle size of fine aggregate is not greater than 0.55mm, fly ash, silica fume, granulated blast furnace The weight of slag and metakaolin is not zero at the same time. In addition, chopped fibers are ad...

Embodiment 2

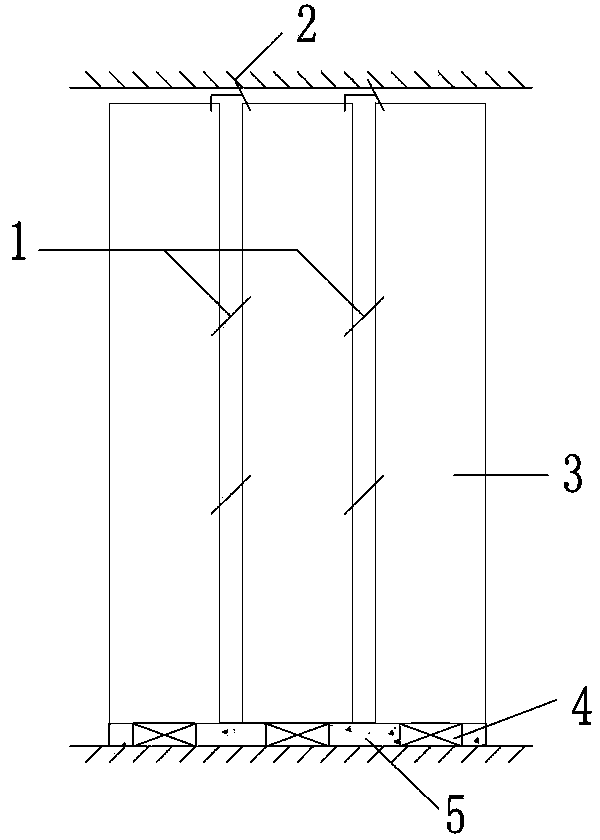

[0024] Embodiment 2, with reference to figure 2 .

[0025] In this embodiment, the wall panels 3 are connected to form a partition wall through oblique iron pins 1; Embed the embedded part 2 for connecting with the top building.

[0026] The specific steps of partition wall construction are as follows: (1) Make the line according to the position of the partition wall in the drawing; (2) Assemble the wall panels 3 according to the installation sequence. During the installation of the wall panels, the prefabricated wall panels are required to be vertical and have a flat surface. Use a ruler to check the verticality and flatness; (3) if figure 2 As shown, the panel and the building on the top of the wall panel are fixed by embedded parts 2, and the wall panels are connected by iron pins 1; (4) Pry up the lower end of the wall panel 3 and drive in the wooden wedge 4 Tighten the wallboard and the building on top of the wallboard, and fill the gap between the wooden wedges 4 wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com