Intelligent polyurethane spraying device and spraying method thereof

A spraying device, polyurethane technology, applied in spraying devices, buildings, building structures, etc., can solve the problems of unstable quality control of finished products, shortening the service life of spray guns, and unsatisfactory spraying effects, improving fluency and avoiding high-altitude operations. , Effortless effect of moving and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

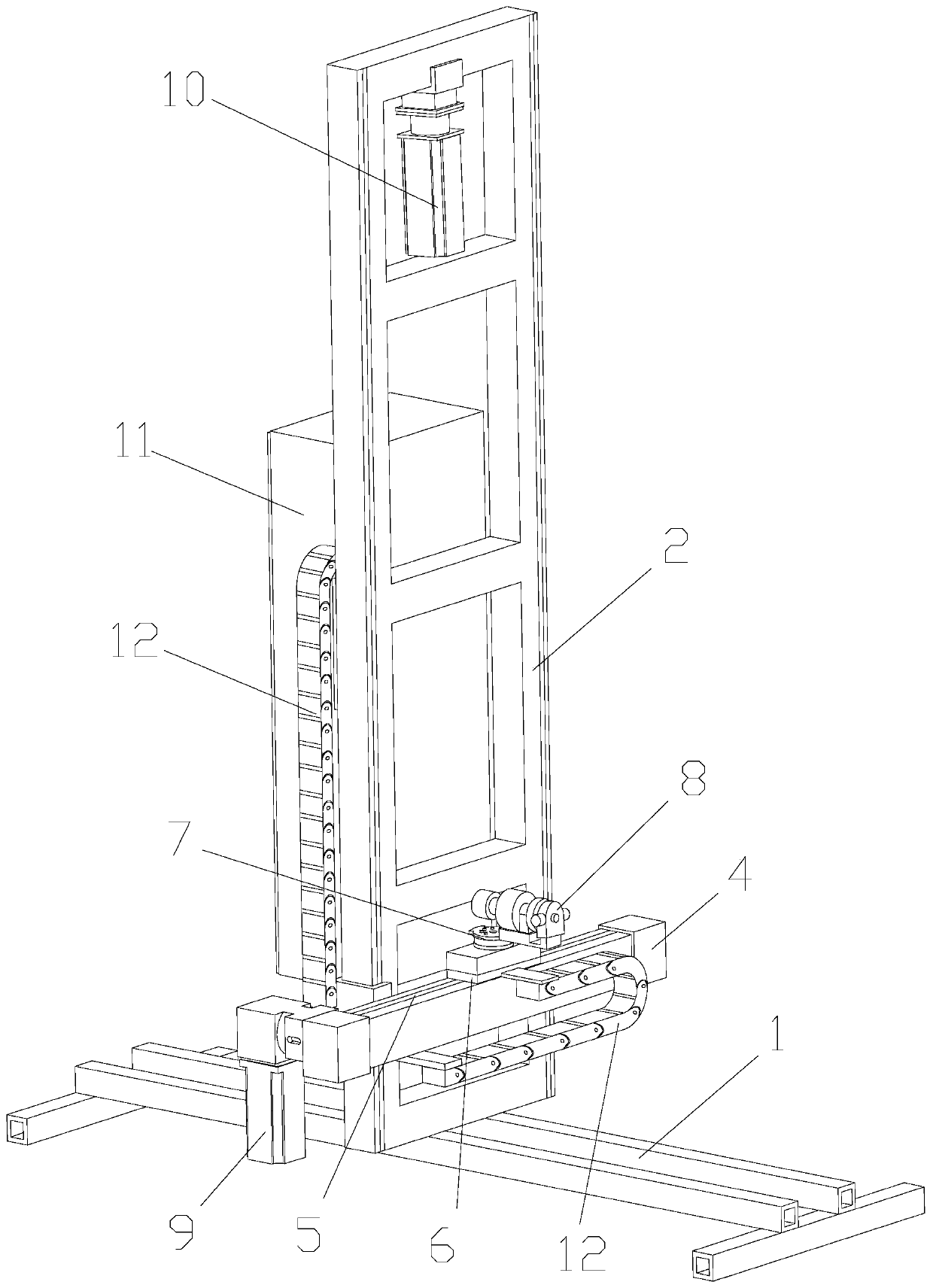

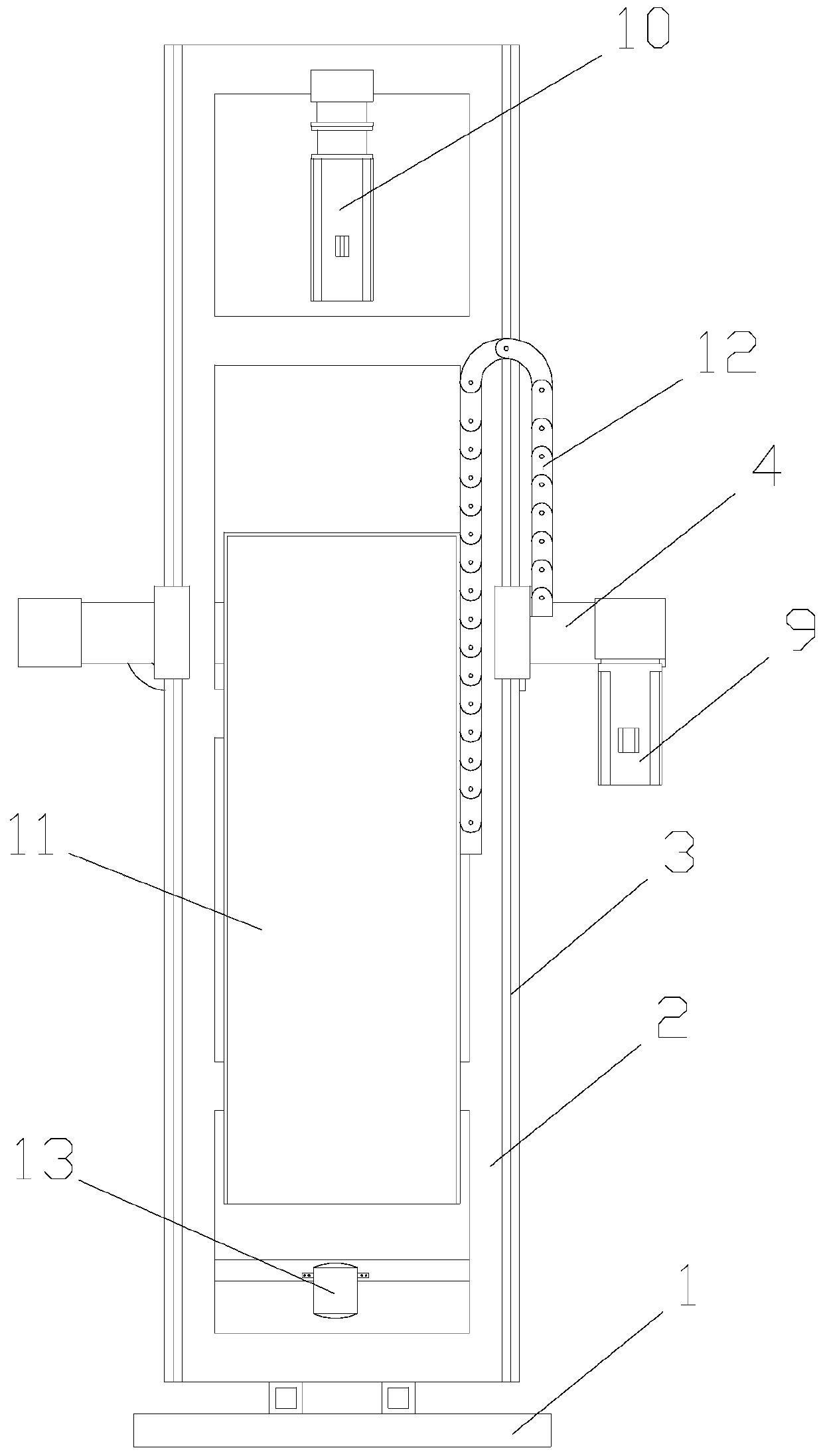

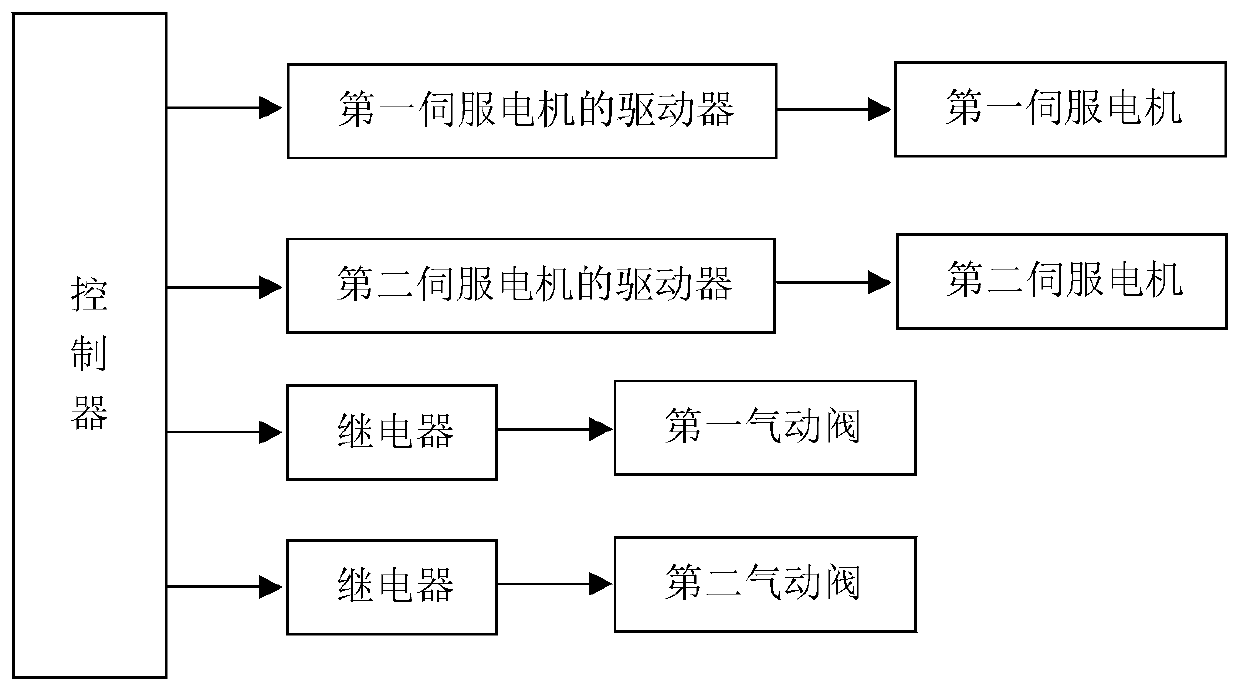

[0039] Such as figure 1 and figure 2 As shown, a kind of intelligent polyurethane spraying device comprises base 1, is provided with vertical fixed support 2 on described base 1, and horizontal mobile support 4 is movably arranged on described vertical fixed support 2, and can be in the first servo Driven by the motor 10, it moves up and down along the vertical guide rail 3 of the vertical fixed bracket 2. The vertical guide rail 3 is arranged on the back side of the vertical fixed bracket 2, which can effectively prevent the polyurethane raw material from spreading and bonding when spraying. On the vertical rail 3, the vertical rail 3 is contaminated. The spray gun support 6 is movably arranged on the horizontally movable support 4, and can move left and right along the horizontal guide rail 5 of the horizontally movable support 4 under the drive of the second servo motor 9. The spray gun 8 is arranged on the described spray gun by swinging and rotating the cylinder 7. On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com