Fluid shunt valve of biomass treatment system

A technology of biomass treatment and shunt valves, applied in valve details, multi-way valves, valve devices, etc., can solve the problem of high valve purchase cost, and achieve the effect of low manufacturing cost and manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

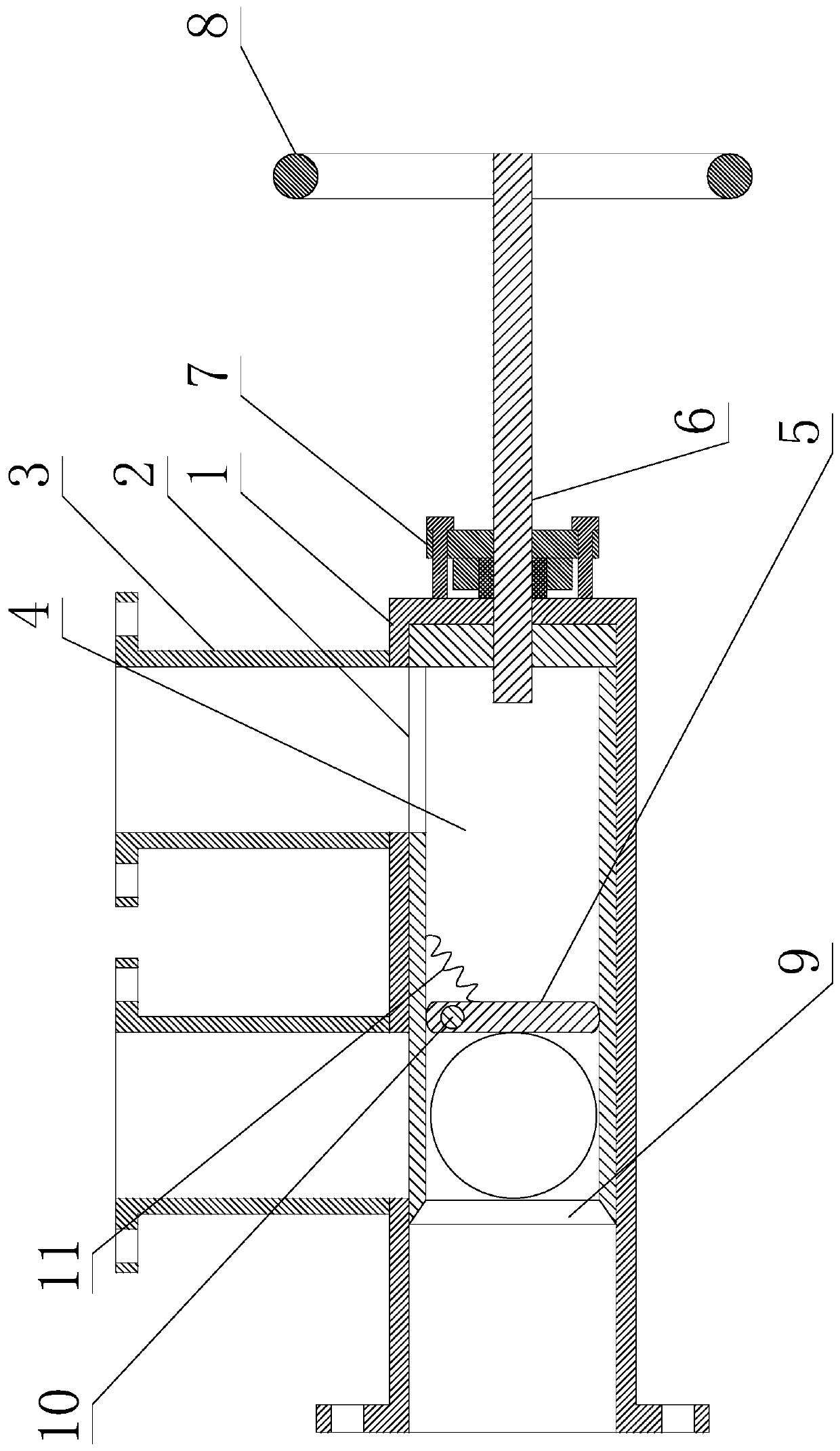

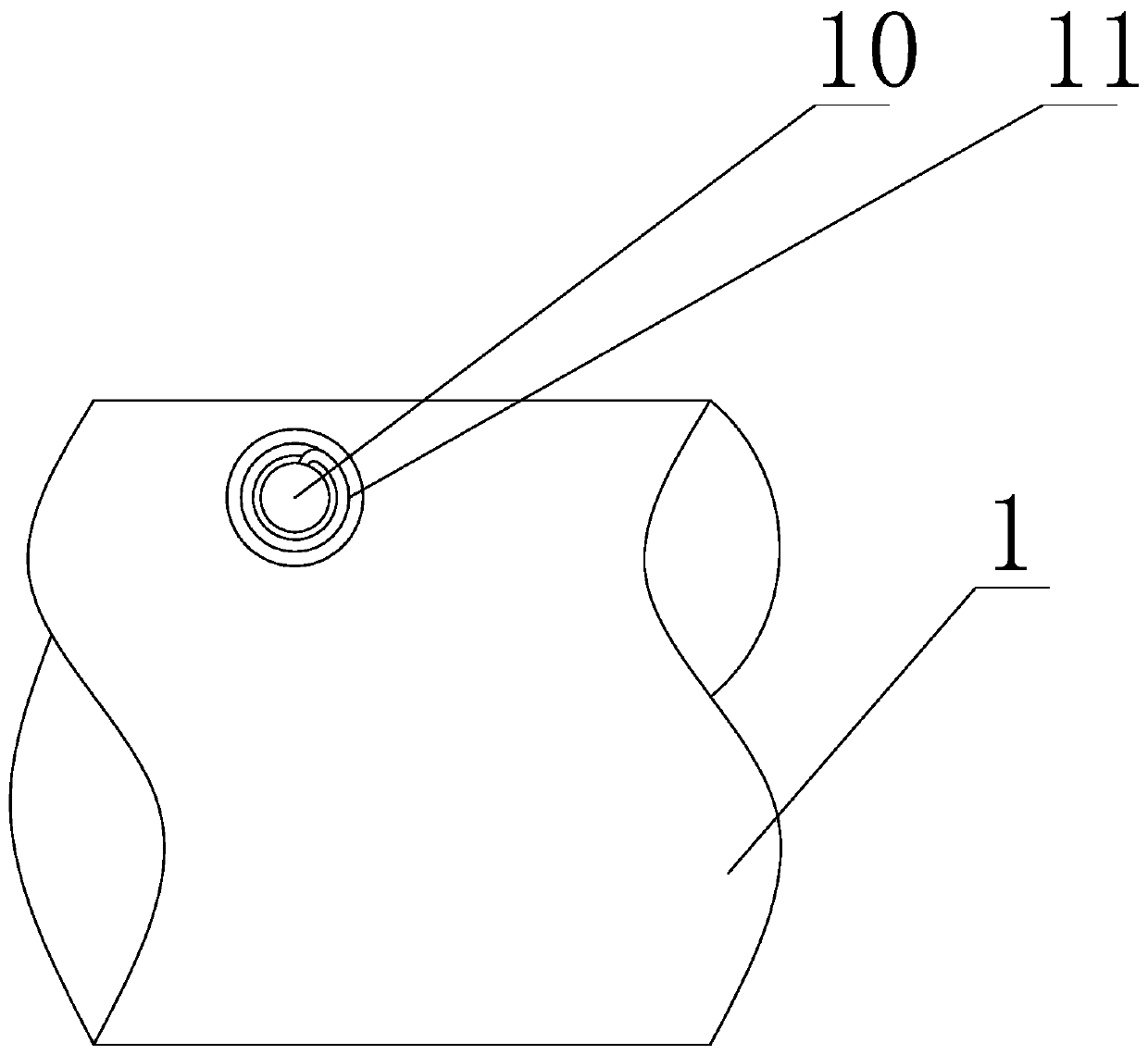

[0040] Such as Figure 1 to Figure 3 As shown, a fluid branch valve of a biomass treatment system includes a valve body and a valve plate 4 installed in the valve body. The valve body includes a dead leg section 1 and two outlet pipes 3. The inlet end of the outlet pipe 3 Both are connected on the side of the dead leg section 1;

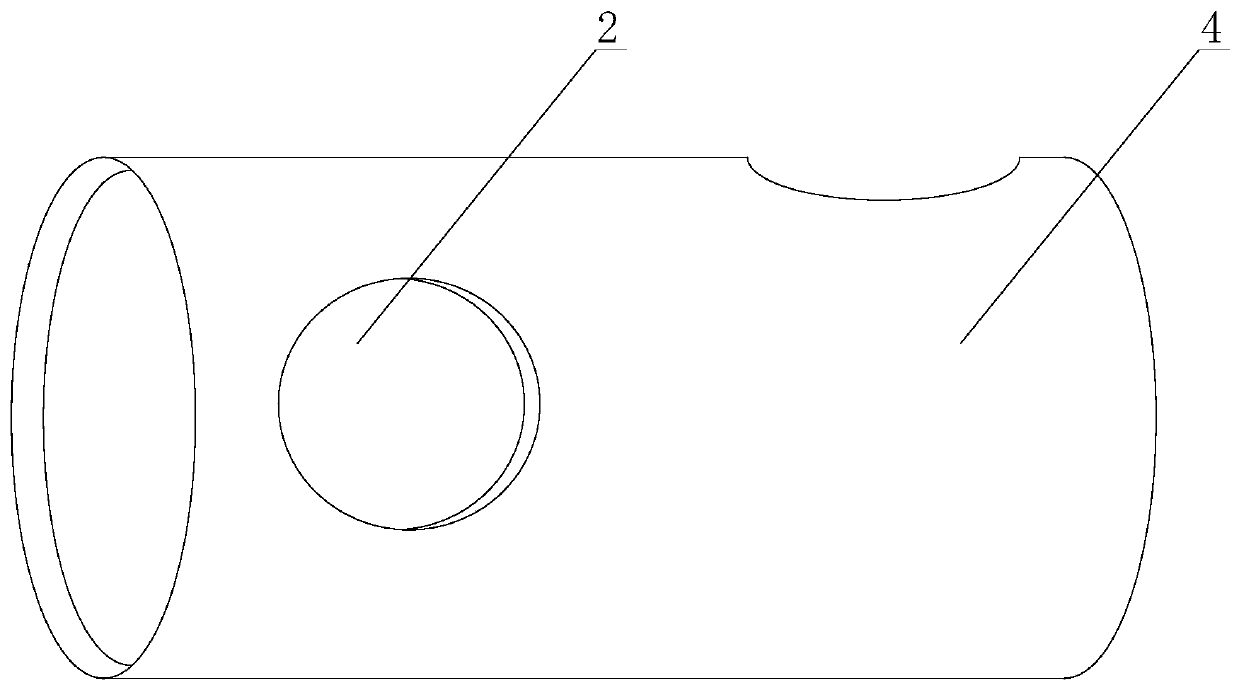

[0041] The valve plate 4 is cylindrical, the valve plate 4 is coaxial with the dead-leg section 1, and the valve plate 4 is installed in the dead-leg section 1, and the outer surface of the valve plate 4 is attached to the inner surface of the dead-leg section 1;

[0042] It also includes a driving mechanism for driving the valve plate 4 to rotate around its own axis. Among the two outlet pipes 3, one of the outlet pipes 3 is pipe A, and the other outlet pipe 3 is pipe B;

[0043] The valve plate 4 is also provided with two communication holes 2, and the communication holes 2 are through holes through the inside and outside of the valve plate 4;

...

Embodiment 2

[0049] The present embodiment is further limited on the basis of embodiment 1, as Figure 1 to Figure 3 As shown, in order to facilitate the laying of the fluid pipeline at the outlet end of the shunt valve, it is arranged that: in the circumferential direction of the dead-leg section 1, the two outlet pipes 3 are connected at the same position in the circumferential direction. As a person skilled in the art, in this solution, the two outlet pipes 3 are located at different axial positions of the dead-leg section 1 .

[0050] In order to avoid the accumulation of dust on the side of the valve plate 4 close to the closed end of the dead-leg section 1 when the outlet pipe 3 close to the inlet end of the dead-leg section 1 is connected to the dead-leg section 1, causing the other outlet pipe 3 to conduct with the dead-leg section 1 When the valve plate 4 is blocked by the accumulated dust, it is set to: also include a flap 5 installed in the valve plate 4 through the second rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com