Overturning displacement full-sealing heat cover system and driving method

A fully-sealed, heat-covered technology, applied in biochemical equipment and methods, biomass post-treatment, bioreactors/fermenters for specific purposes, etc. Large, high production costs and other issues, to achieve the effect of improving experimental efficiency and accuracy, small overall structure size, reducing manufacturing cost and manufacturing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

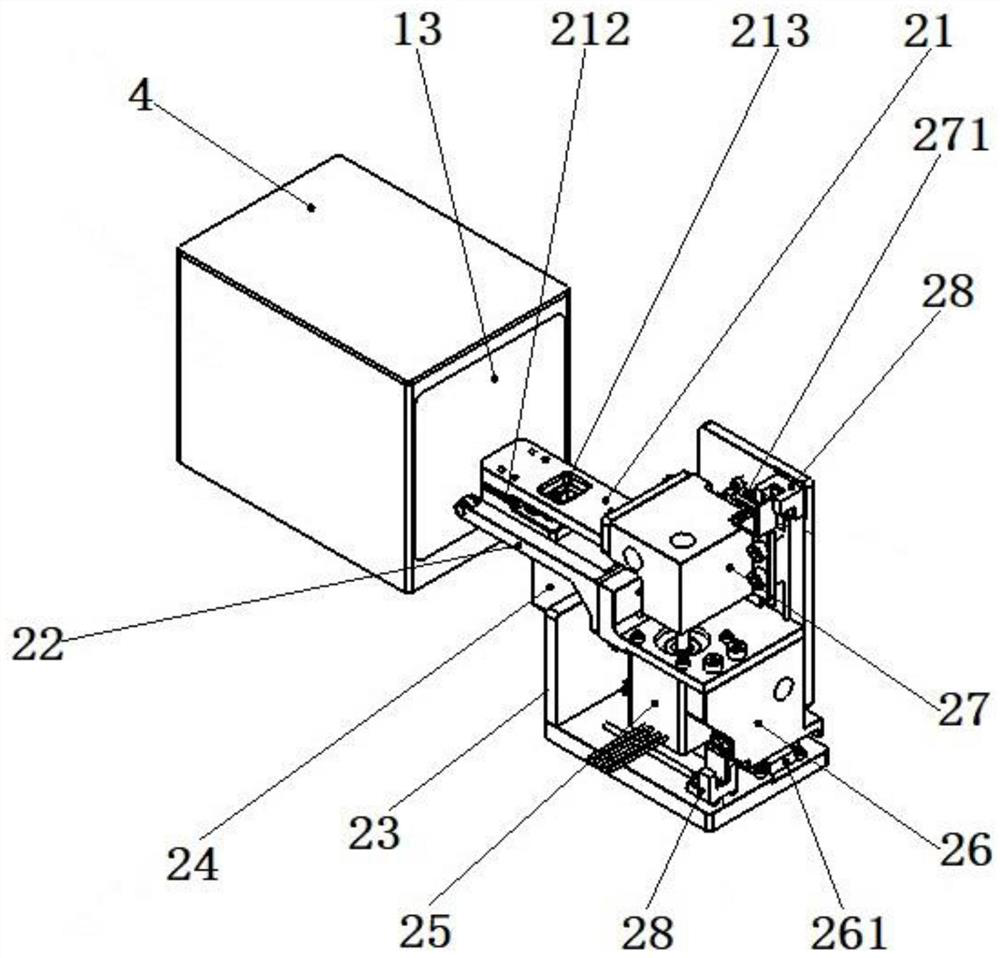

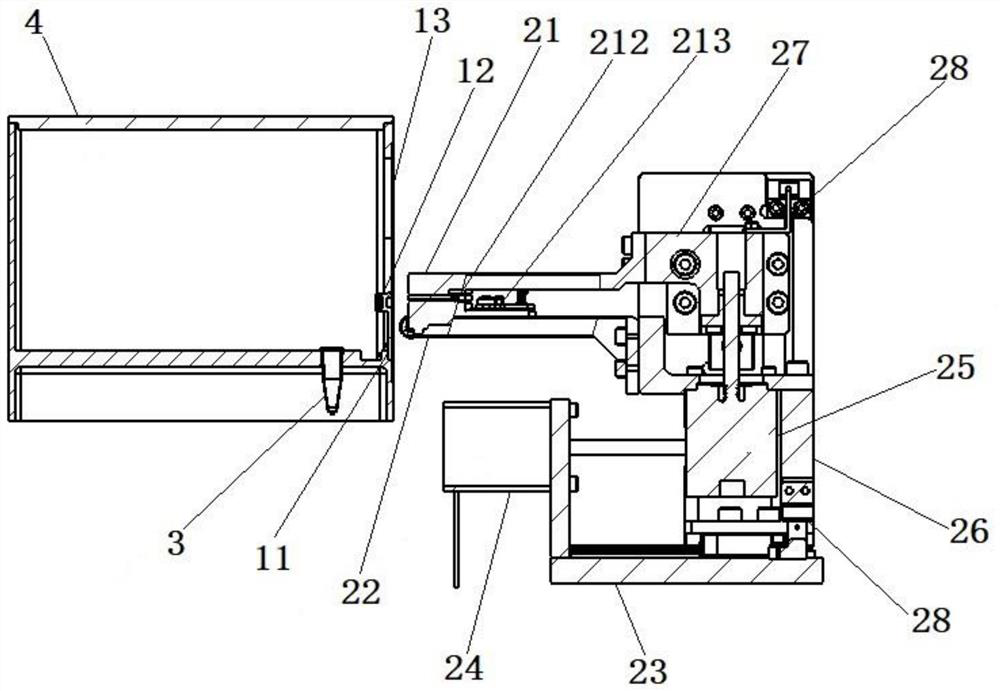

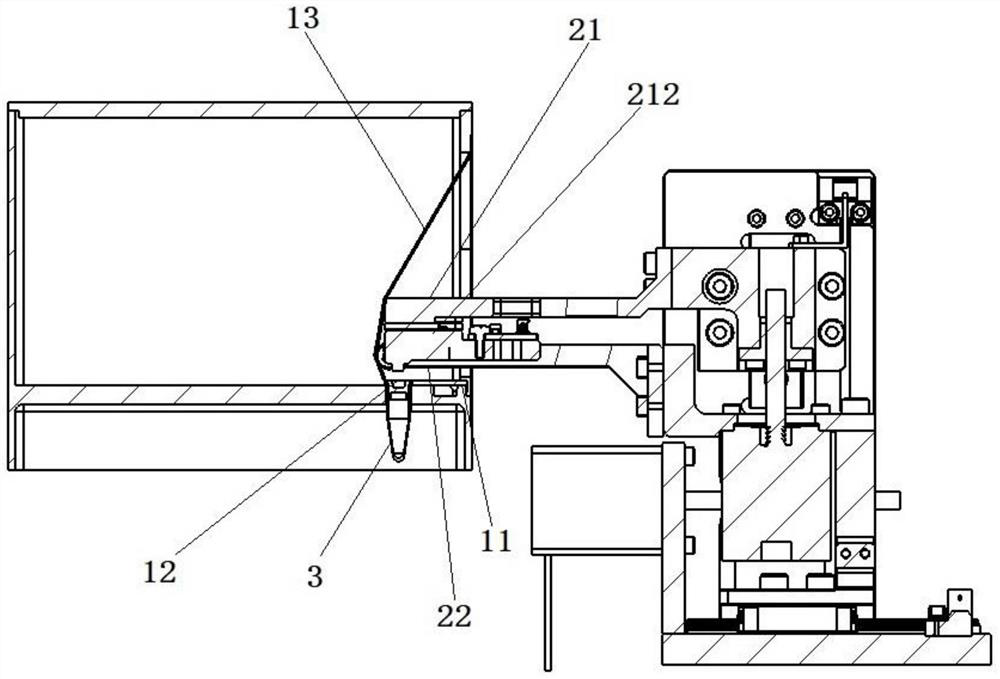

[0036] In order to understand the content of the present invention more clearly, detailed description will be given in conjunction with the accompanying drawings and embodiments.

[0037] The use of the hot lid system to heat the reaction wells during the library preparation process must simultaneously ensure the integrity of the library preparation cassette and the requirements of not affecting the operability of other functional components, that is, the hot lid (lid assembly) is essentially required not only to perform a single dimension In order to realize the normal closing and opening operation of the hot lid, it is also necessary to provide an appropriate displacement method to ensure that the operating space directly above the reaction well can be released when the hot lid is open for other functional components (such as pipettes) in the cassette to adjust. The reaction wells are operated. The more complex displacement requirement not only brings problems to the sealing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com