Quick-opening valve and prepared explosion suppressor applying quick-opening valve

A technology of antiknock agent and valve body, which is applied in safety valves, balance valves, valve devices, etc., can solve problems such as poor safety performance, small opening diameter, and long response time, and achieve fast response time, large opening diameter, and spray The effect of high powder efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

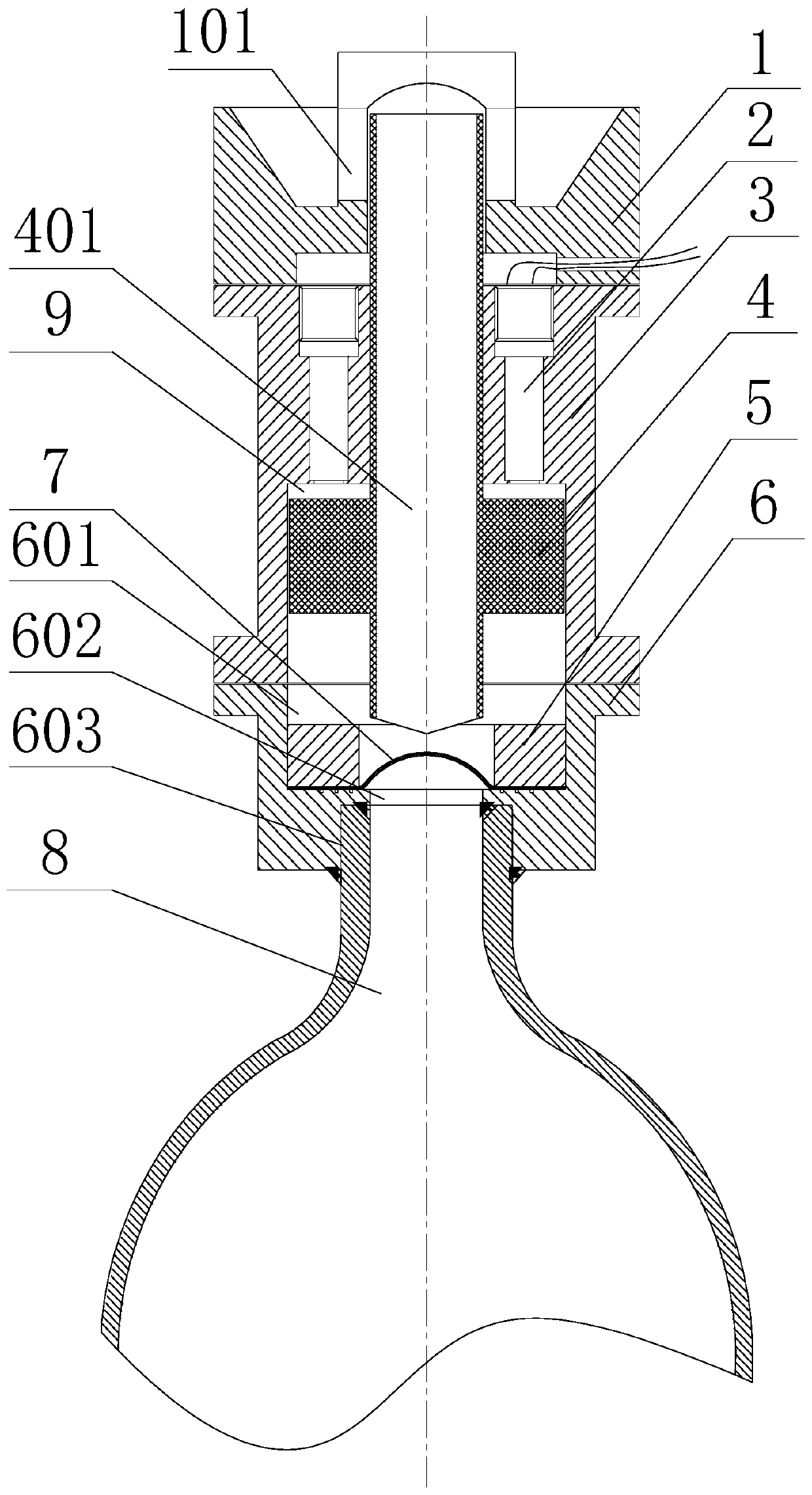

[0032] see figure 1 , a quick-opening valve, including a bursting disc 7 and a valve body, as well as an impact rod 4 and a trigger device arranged in the valve body; one end of the valve body is provided with an inlet channel 602 for the detonation agent, and the other end is provided with an inlet channel 602 for the detonation agent Diffusion channel 101, the impact rod 4 is provided with an outflow channel 401 of antiknock agent, the diffusion channel 101 communicates with the inlet channel 602 through the outflow channel 401; the bursting disc 7 is covered on the inlet channel 602, and the impact rod 4 is slidingly connected with the valve body, The impact rod 4 moves toward the bursting disc 7 under the action of the triggering device to pierce the bursting disc 7, so that the inlet channel 602 communicates with the outflow channel 401 .

[0033] The valve body includes a valve upper cover 1, a valve middle section 3 and a valve lower section 6 arranged in sequence; the ...

Embodiment 2

[0047] An explosion suppressor, comprising an explosion suppressant storage tank and a quick-open valve arranged thereon, wherein the quick-open valve applies the quick-open valve in Embodiment 1; the explosion-suppressant storage tank has a flange, and the quick-open valve in the The third stepped hole is sealed and fixedly connected with the flange.

[0048] In order to increase the connection strength between the valve body and the anti-knock agent storage tank, the connection between the lower section of the valve and the anti-knock agent storage tank is full welding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com