Super-strength waterproof LED light-emitting module and processing method

A light-emitting module and super-strength technology, applied in the direction of gas-proof/waterproof devices, semiconductor devices of light-emitting elements, light sources, etc., can solve problems such as insufficient fusion strength, poor waterproof performance, and decline in waterproof grades, achieving low cost, Easy to automate production, improve the effect of waterproof level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

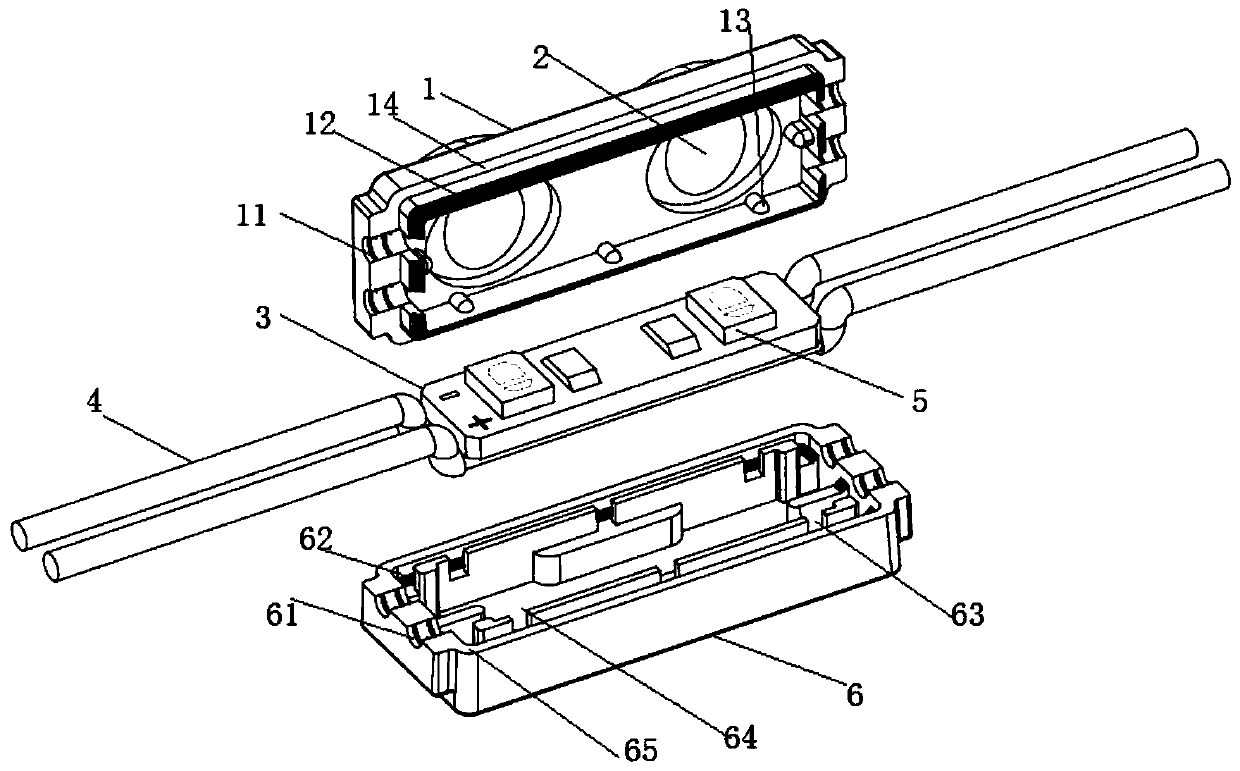

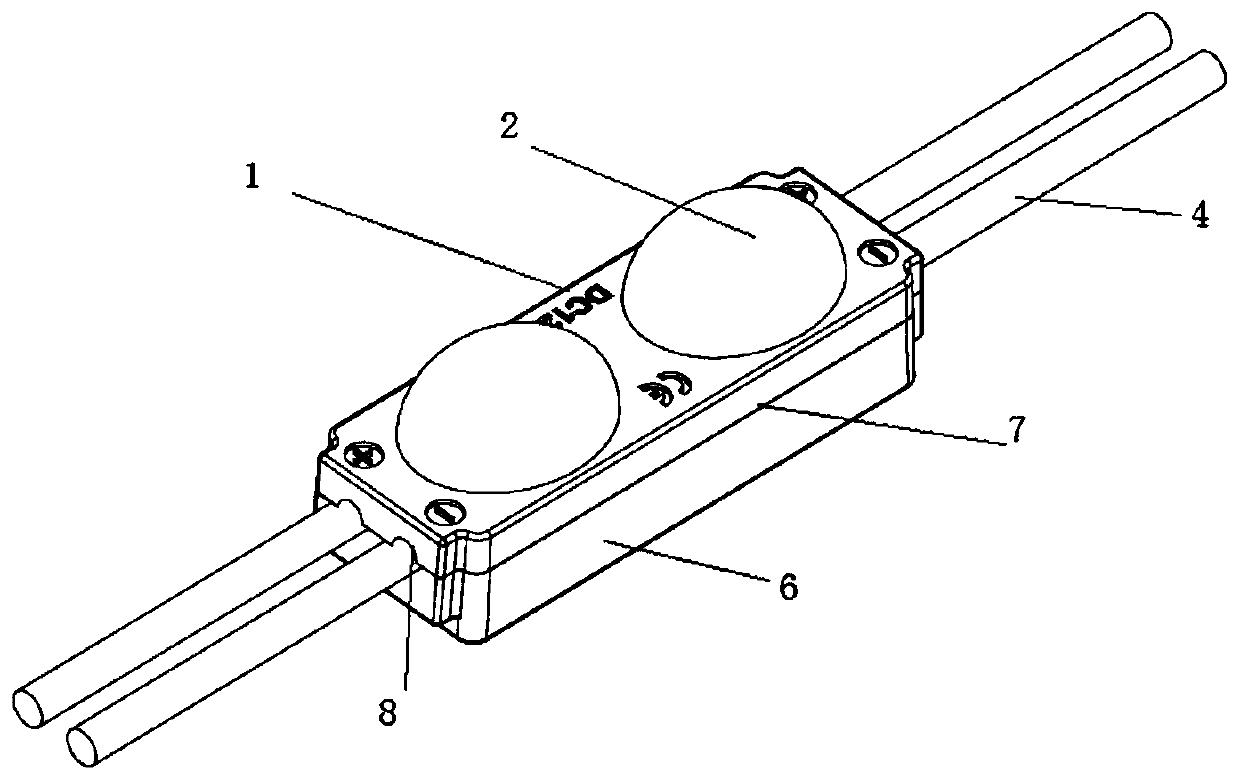

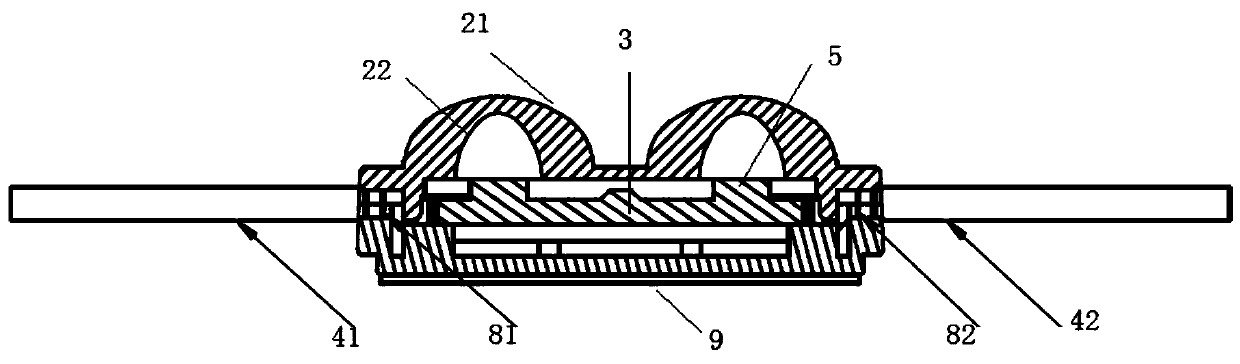

[0023] Such as Figure 1-Figure 3 As shown, the super-strength waterproof LED lighting module of the present invention includes a casing and a light source module arranged inside the casing, and the light source module includes a PCB (printed circuit board) 3 and LEDs arranged on the PCB 3 Lamp bead 5, the LED light-emitting module also includes wires 4 connected to both ends of the PCB board 3, the two ends of the housing are respectively provided with lead-out channels for interference fit with the wires 4, and the lead-out channels are connected to the wires 4 Threads are provided on the mating surface, and the sheath of the wire 4 is welded to the thread of the lead-out channel.

[0024] The material of the wire sheath of this example can be PVC (polyvinyl chloride) or PU (polyurethane is called for short polyurethane) and other common ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com