A Laser Measuring Probe Device for Measuring Arbitrary Surface Shape and Position Errors

A laser measurement and error technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve Abbe error and other problems, achieve the effect of reducing dust entry, high displacement transmission accuracy, good market application prospects and promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

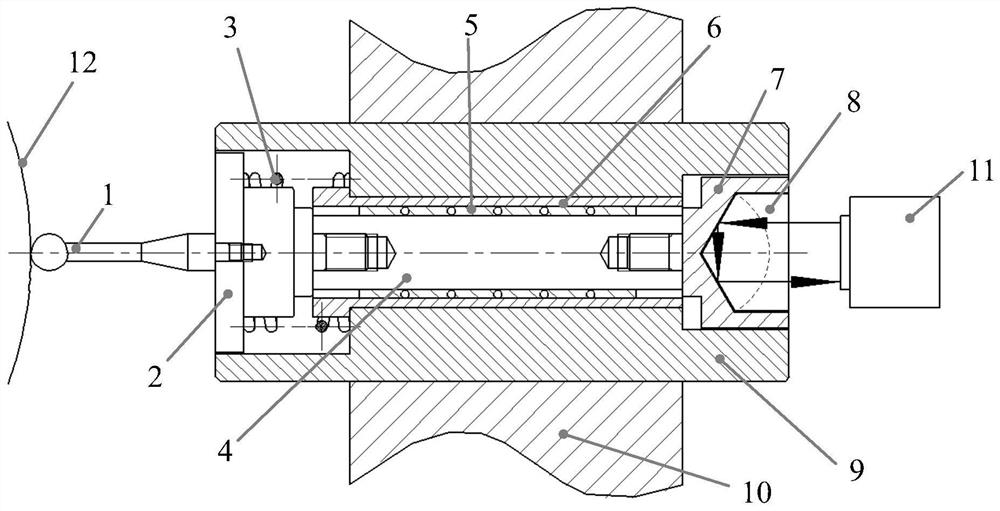

[0023] Taking the measurement of any curved surface as an example, the specific implementation method of the present invention is described.

[0024] 1) In order to ensure the smoothness of the displacement transmission of the device, the material of the spring limit plate 2 and the target mirror mounting seat 7 is 304 stainless steel or TC4 titanium alloy;

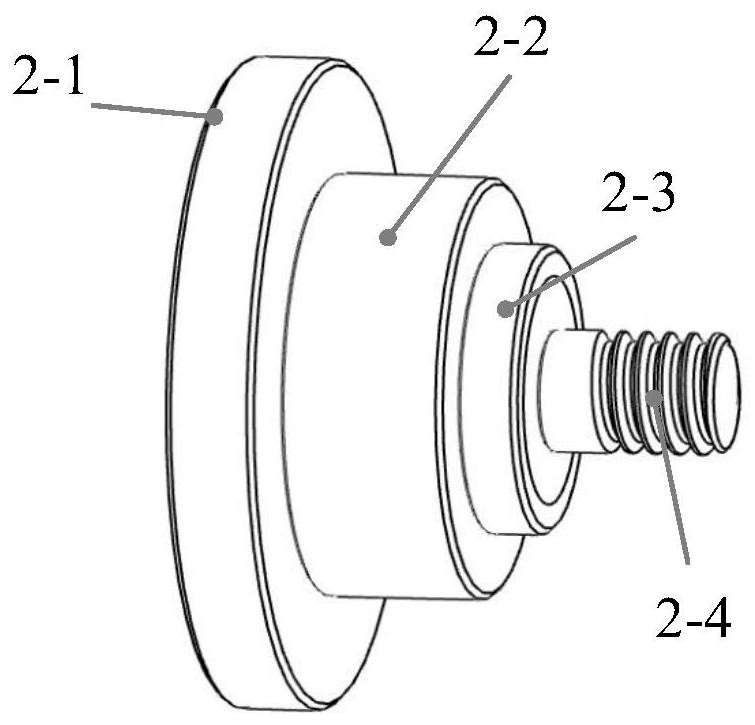

[0025] 2) Before assembly, refine the spring limit plate 2, guide shaft 4, bushing 6 and target mirror mounting seat 7, and use the high-precision grinding plate that has been lapped to the spring limit plate boss A2-1, spring The limit plate boss C2-3, the end face of the guide shaft 4, the end face of the target mirror mounting seat shaft section A7-1, and the target mirror mounting seat shaft section B7-2 are refined; The hole is refined; the guide shaft 4 is refined by using a high-precision grinding ring; after refinement, the flatness error of the end faces of the spring limit disc boss A2-1 and the spring limit dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com