Servo adjustable pendulum impact tester

An impact testing and adjustable technology, applied in impact testing, machine/structural component testing, measuring devices, etc., can solve the problems of inaccurate test results, poor equipment, unsatisfactory, etc., and achieve high test efficiency and test results. The effect of accurate and convenient loading and unloading operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

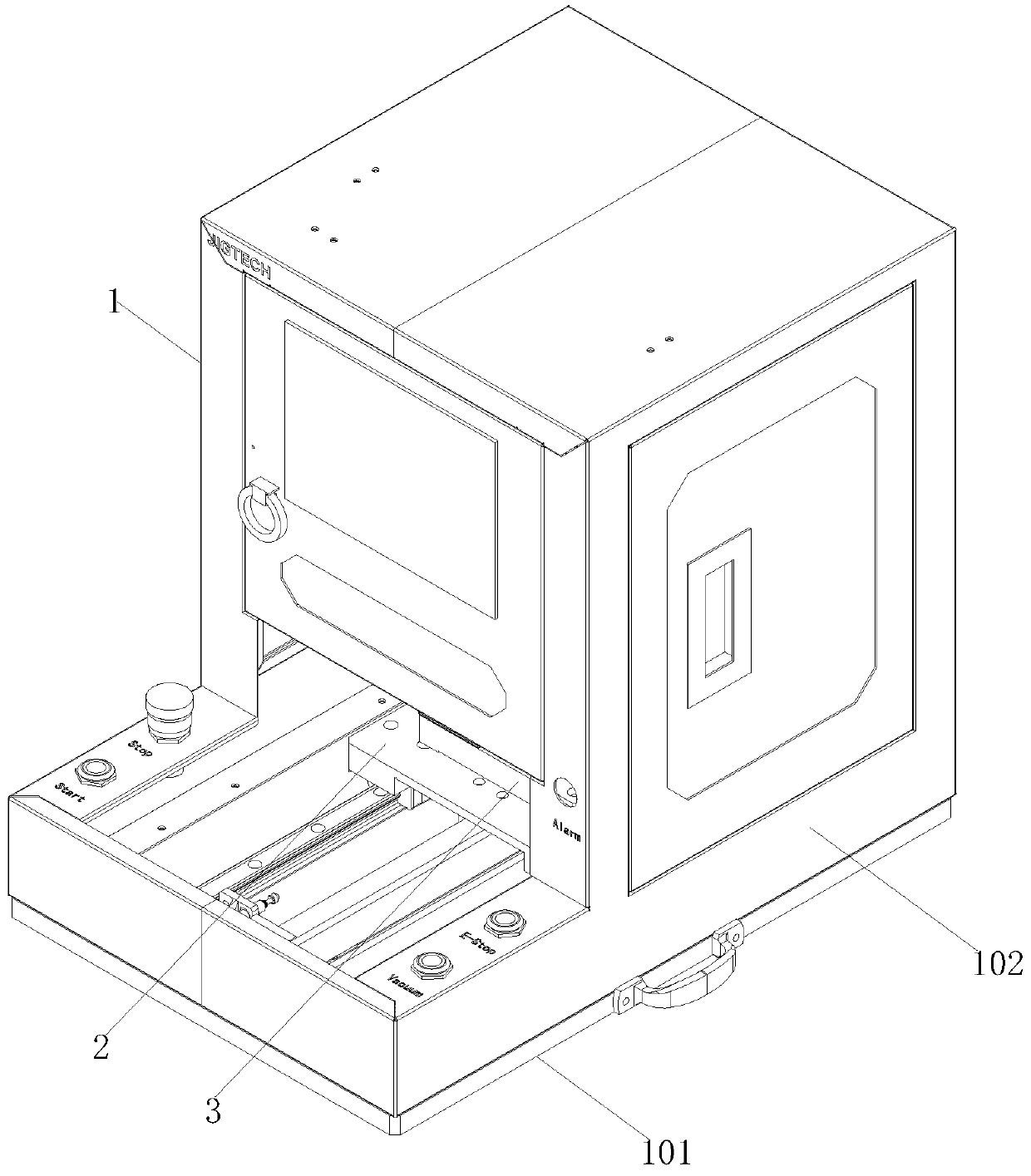

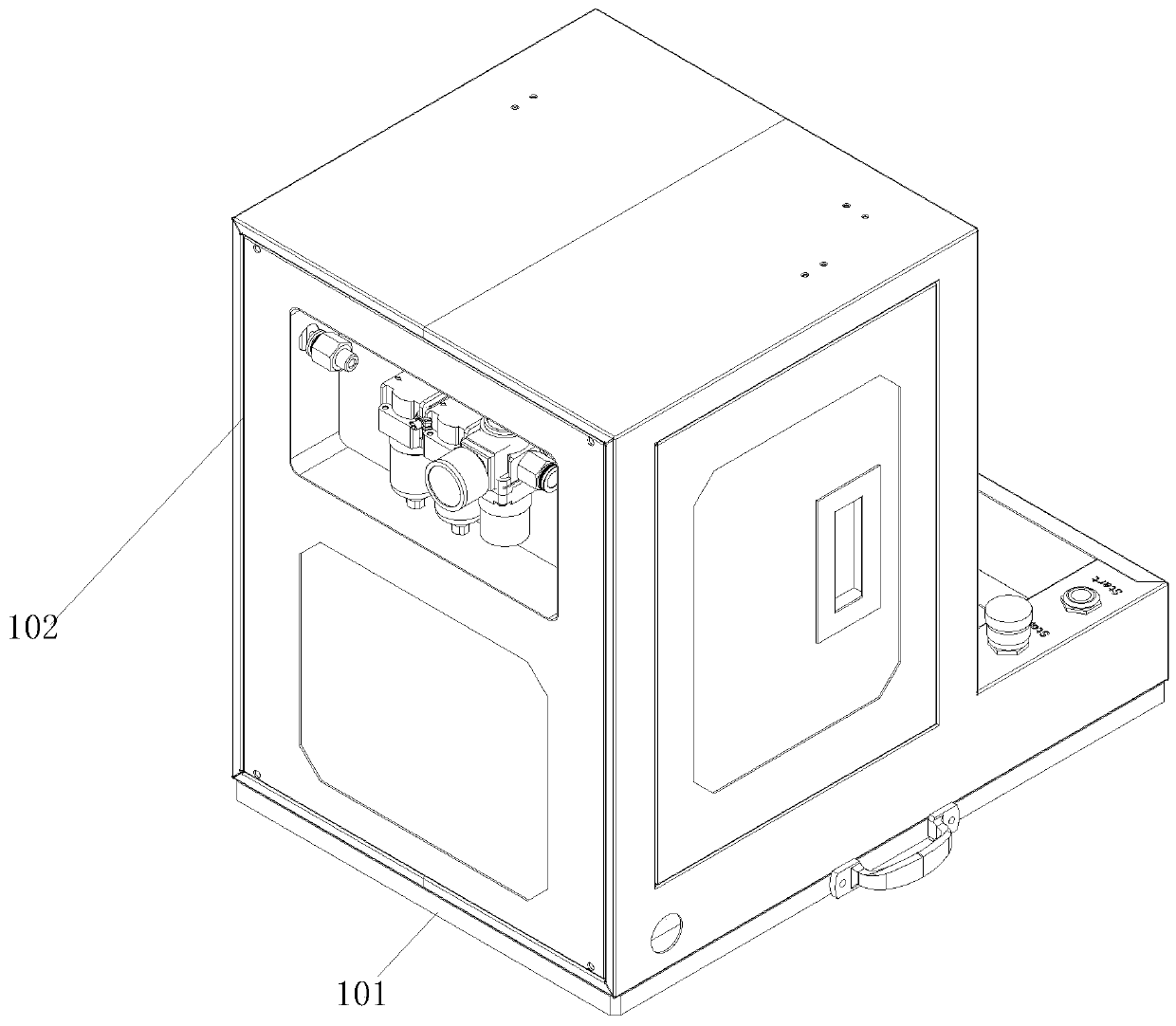

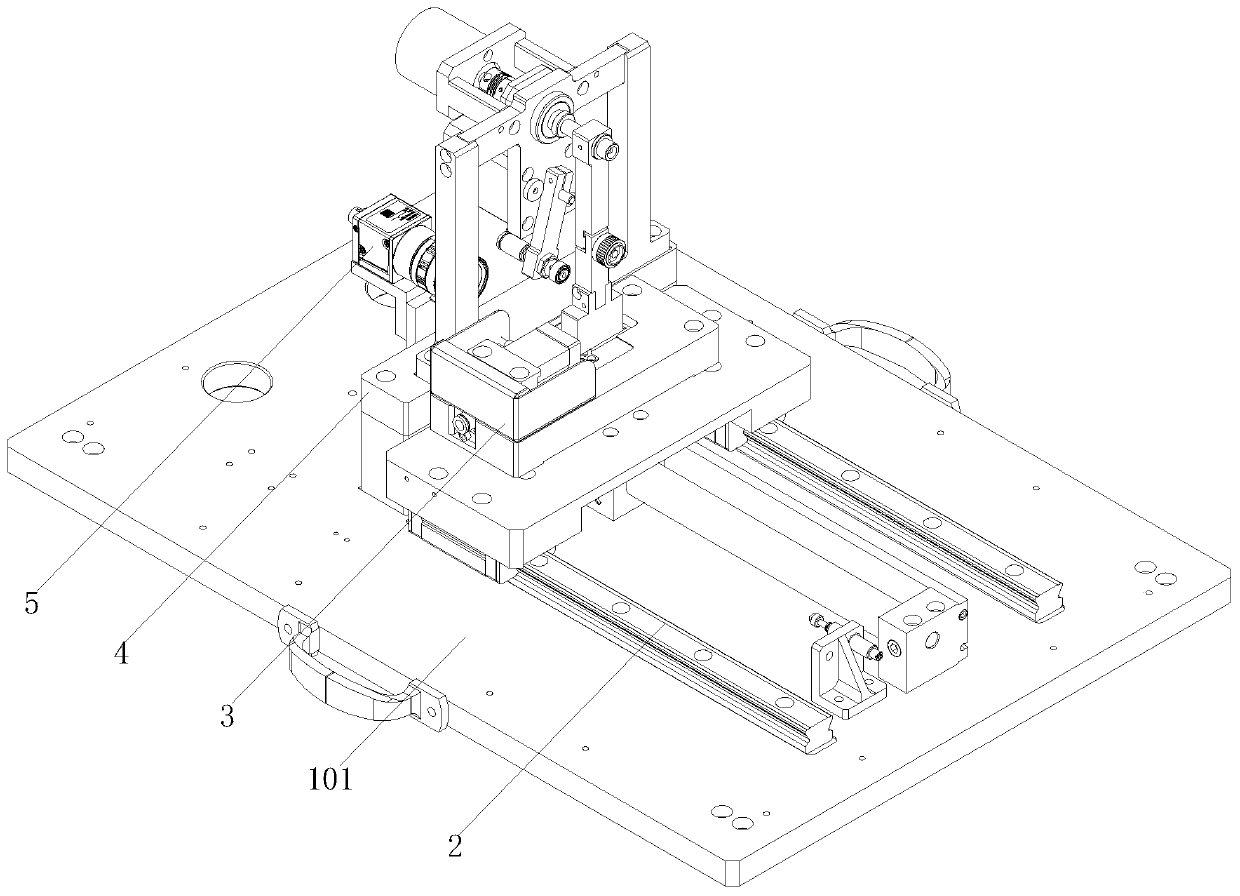

[0029] see Figure 1-9 , the present invention provides the following technical solutions: a servo-adjustable pendulum impact testing machine, comprising: a frame assembly 1; the frame assembly 1 includes a bottom plate 101, and the top of the bottom plate 101 is fixedly installed with an organic frame 102; a feeding mechanism 2, a feeding mechanism 2 is fixed on the bottom plate 101, which is used to drive the chip to move in the machine frame 102; the clamp assembly 3, which is fixed on the feeding mechanism 2, is used to fix the chip to be tested; the pendulum clock mechanism 4, The pendulum clock mechanism 4 is fixed on the base plate 101, and it is used for impact testing the chip on the fixture assembly 3; the photographing mechanism 5, the photographing mechanism 5 is fixed on the base plate 101, and it is used for photographing and recording the chip in the impact test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com