Numerical control machine tool magazine control method based on EtherCAT bus

A technology of numerical control machine tools and control methods, applied in digital control, program control, electrical program control, etc., can solve the problems of cumbersome programs, disordered control, inconvenient maintenance, etc., and achieve flexible topology, improved stability, and easy application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

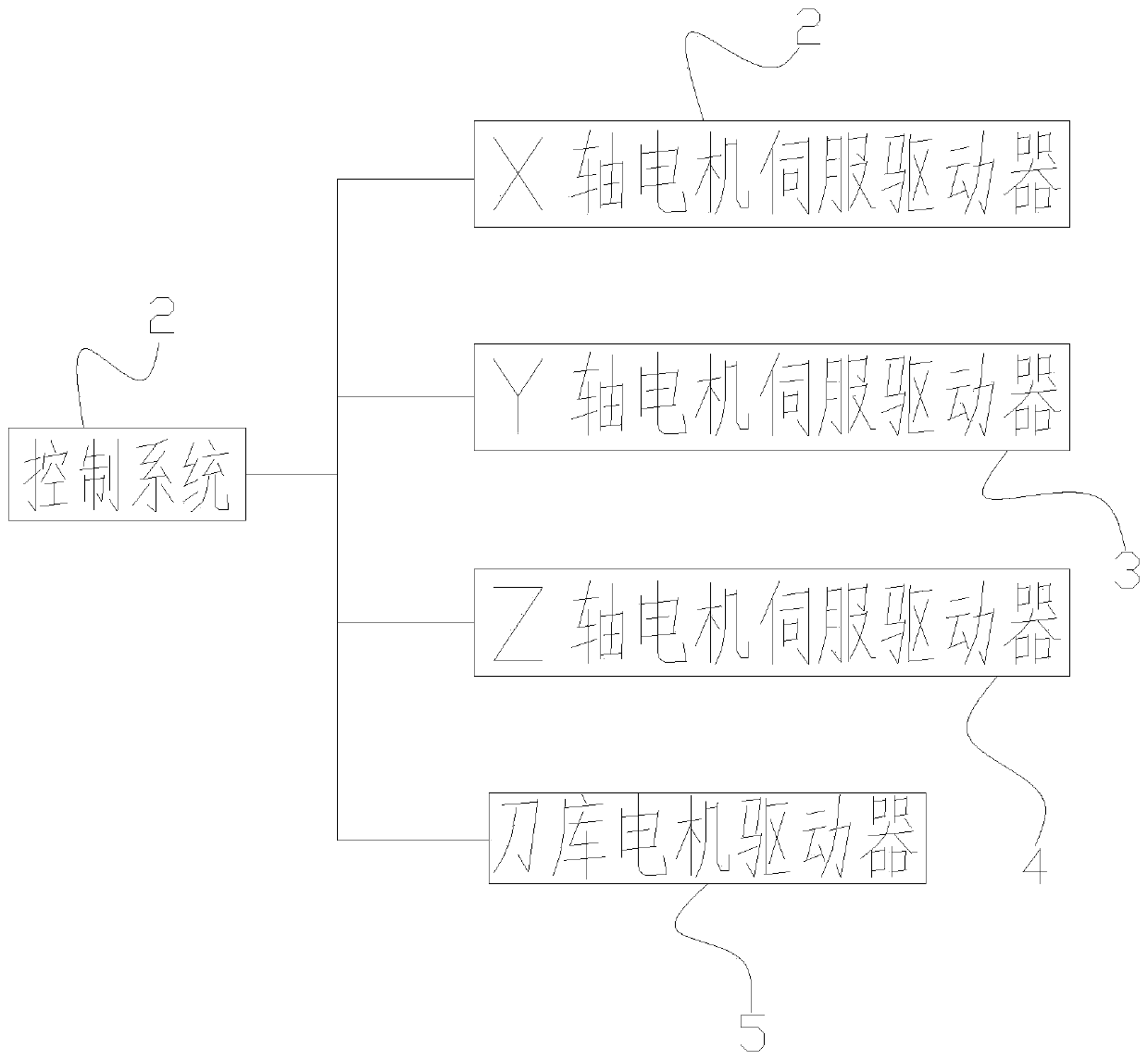

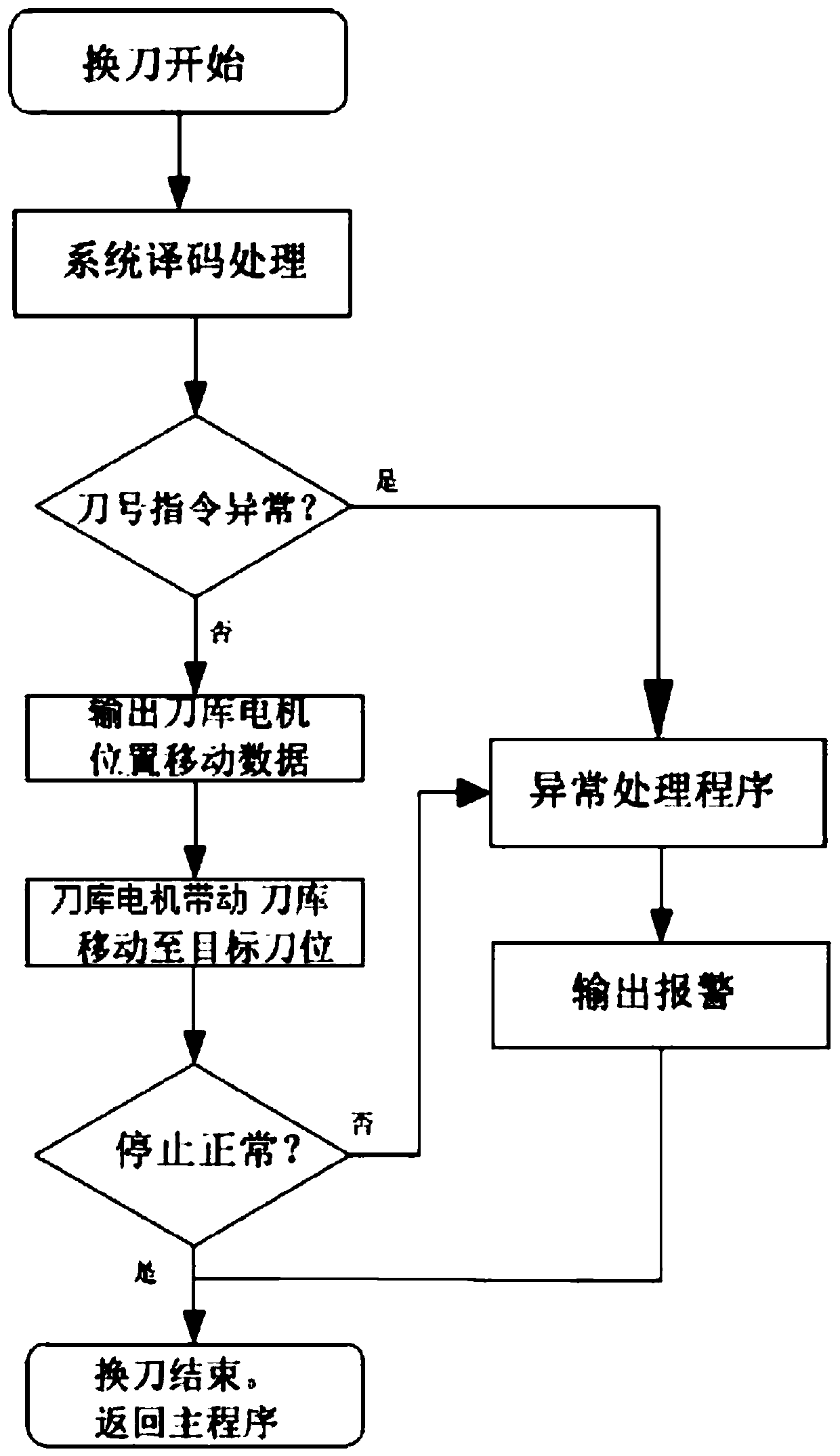

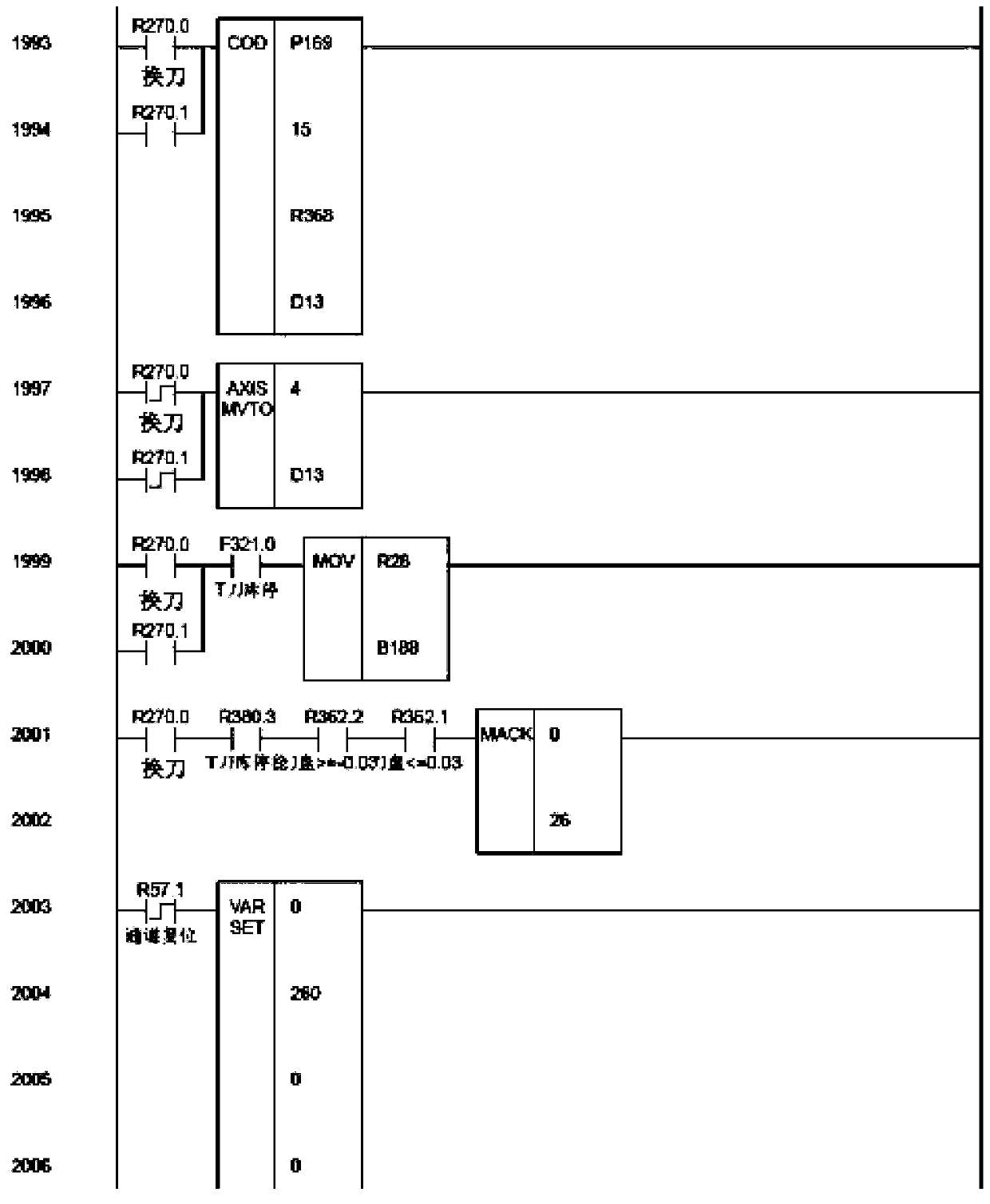

[0019] Such as Figure 1-3 Shown, a kind of CNC machine tool magazine control method based on EtherCAT bus comprises numerical control system 1, and described control system 1 is connected with X-axis motor servo driver 2, Y-axis motor servo driver 3, Z-axis motor servo driver 4 and knife respectively Library motor driver 5, including control system 1 Huazhong 8 type CNC milling device HNC818D, X-axis motor servo driver 2 and Y-axis motor servo driver 3 model is Inovance IS620NT3R5I-HW; Z-axis motor servo driver 4 model is Inovance IS620NT5R4I- HW, the input voltage of X-axis motor servo driver 2, Y-axis motor servo driver 3 and Z-axis motor servo driver 4 is , the input voltage specification is three-phase AC380V-440V±10%, and the voltage frequency is 50 / 60Hz; the X-axis moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com