Copper pillar spacer with stress buffer and anisotropic conduction and method of making the same

An anisotropic, stress-buffering technology, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems such as downward offset, offset reduction, and increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

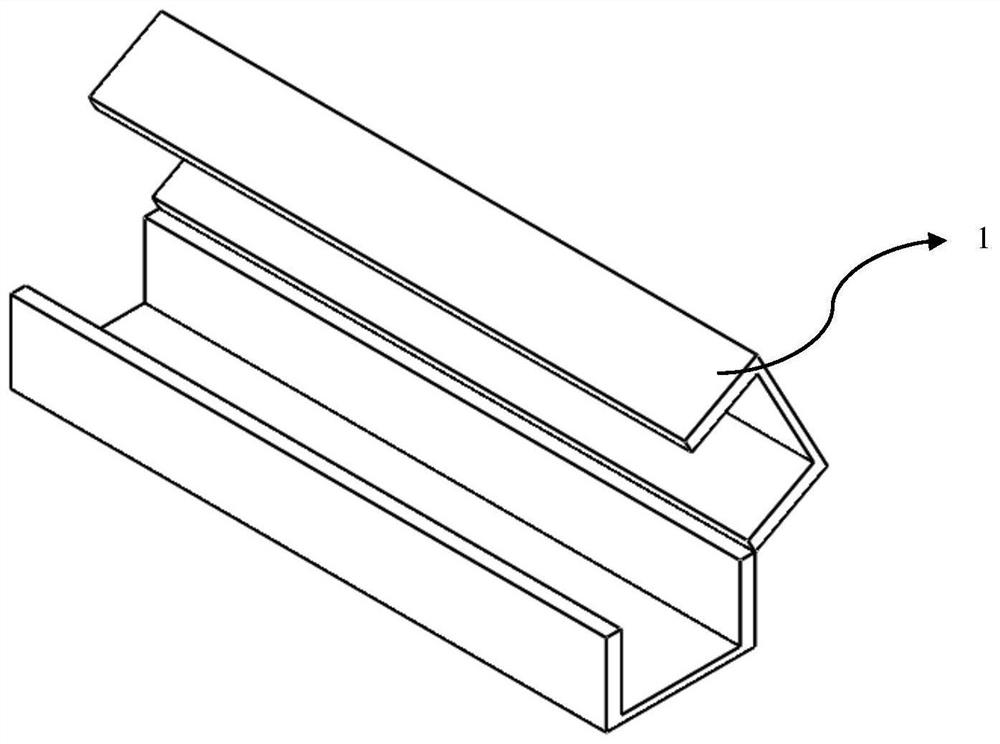

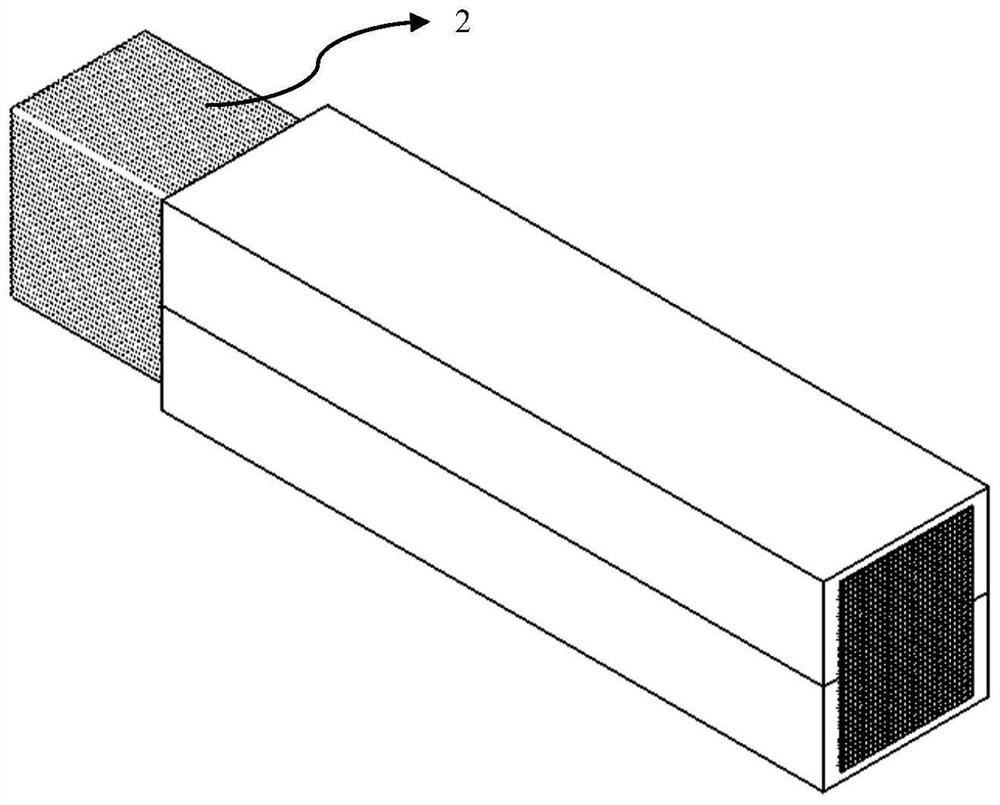

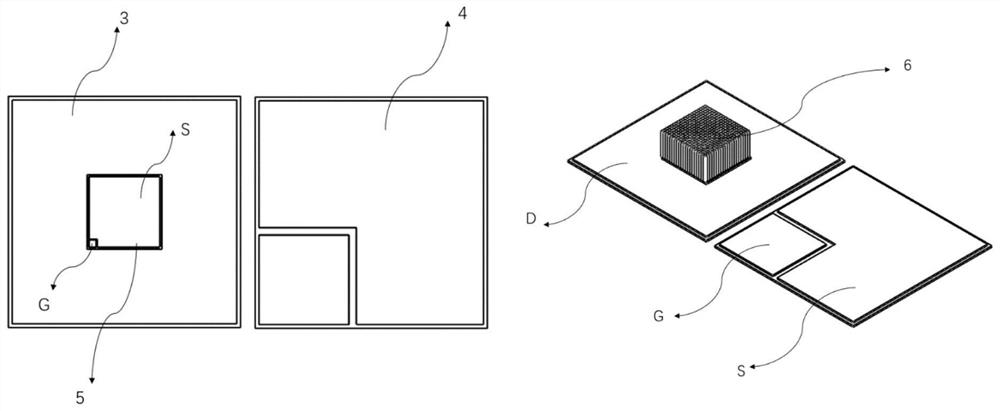

[0017] In view of the above situation, the present invention discloses a preparation method of a copper column spacer based on insulated copper wire that can realize stress buffering and anisotropic conductivity. The new copper column spacer can be used for double-sided heat dissipation / planar electronic devices and modules The encapsulation of several insulated copper wires with a diameter of about 0.3 ~ 0.5mm is bonded together with an epoxy resin polymer adhesive to form a copper wire of a specific shape, and then the copper wire is processed to the required height to replace the Metal posts in double-sided modules.

[0018] Technical scheme of the present invention is as follows:

[0019] The invention discloses a preparation method of a copper column cushion block capable of realizing stress buffering and anisotropic conduction based on insulated copper wires; several insulated copper wires with a diameter of about 0.3 to 0.5 mm are put into a circular or square half-open...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com