Decontamination device with self-priming double Venturi structure and its application

A Venturi and double Venturi technology, which is applied in the field of decontamination devices with self-priming double Venturi structures, can solve the problems of single arrangement, inability to meet the emergency decontamination of toxic gases, and low washing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

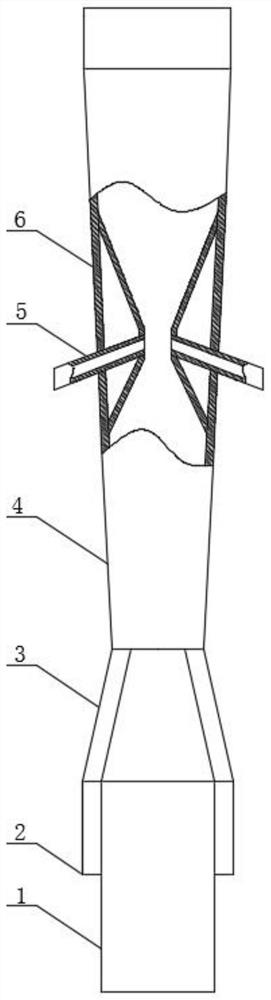

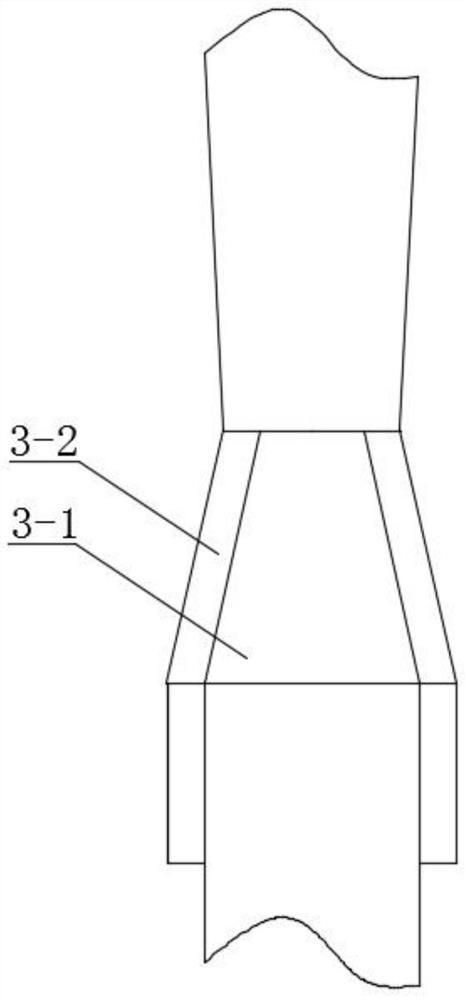

[0025] A decontamination device with a self-priming double Venturi structure, such as Figure 1-Figure 2 As shown, this patent discloses a self-priming double-venturi structure decontamination device for gas-liquid treatment, which consists of a gas straight pipe inlet 1, a liquid annular inlet 2, a Venturi tapering section 3, and a Venturi expansion section 4 , a built-in Venturi liquid inlet pipe 5 and a built-in Venturi section 6. Among them, the liquid annular inlet 2 is located above the gas straight pipe inlet 1, and is connected to the Venturi tapering section 3 after passing through a straight pipe. The Venturi tapering section 3 is divided into two areas: the inner area 3-1 and the outer area 3-2: The inner area 3-1 only circulates gas, the outer area 3-2 only circulates liquid, and its top is connected with the Venturi expansion section 4 . The built-in Venturi liquid inlet pipe 5 is connected with the built-in Venturi section 6, and the external pipe section must b...

Embodiment 2

[0032] A decontamination device with a self-priming double Venturi structure, such as Figure 1-Figure 2As shown, this patent discloses a self-priming double-venturi structure decontamination device for gas-liquid treatment, which consists of a gas straight pipe inlet 1, a liquid annular inlet 2, a Venturi tapering section 3, and a Venturi expansion section 4 , a built-in Venturi liquid inlet pipe 5 and a built-in Venturi section 6. Among them, the liquid annular inlet 2 is located above the gas straight pipe inlet 1, and is connected to the Venturi tapering section 3 after passing through a straight pipe. The Venturi tapering section 3 is divided into two areas: the inner area 3-1 and the outer area 3-2: The inner area 3-1 only circulates gas, the outer area 3-2 only circulates liquid, and its top is connected with the Venturi expansion section 4 . The built-in Venturi liquid inlet pipe 5 is connected with the built-in Venturi section 6, and the external pipe section must be...

Embodiment 3

[0040] A decontamination device with a self-priming double Venturi structure, such as Figure 1-Figure 2 As shown, this patent discloses a self-priming double-venturi structure decontamination device for gas-liquid treatment, which consists of a gas straight pipe inlet 1, a liquid annular inlet 2, a Venturi tapering section 3, and a Venturi expansion section 4 , a built-in Venturi liquid inlet pipe 5 and a built-in Venturi section 6. Among them, the liquid annular inlet 2 is located above the gas straight pipe inlet 1, and is connected to the Venturi tapering section 3 after passing through a straight pipe. The Venturi tapering section 3 is divided into two areas: the inner area 3-1 and the outer area 3-2: The inner area 3-1 only circulates gas, the outer area 3-2 only circulates liquid, and its top is connected with the Venturi expansion section 4 . The built-in Venturi liquid inlet pipe 5 is connected with the built-in Venturi section 6, and the external pipe section must b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com