Splicing method for splicing multiple mold core loosen pieces to form annular mold core

A core and live block technology, applied in the direction of core, mold composition, mold, etc., can solve the problem of affecting the bonding quality of the finished annular ceramic core, the liquid glue does not have high temperature resistance, and the error of the joint surface is large, etc. problems, to achieve the effect of improving the efficiency of splicing and assembly, reducing errors and ensuring the quality of bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

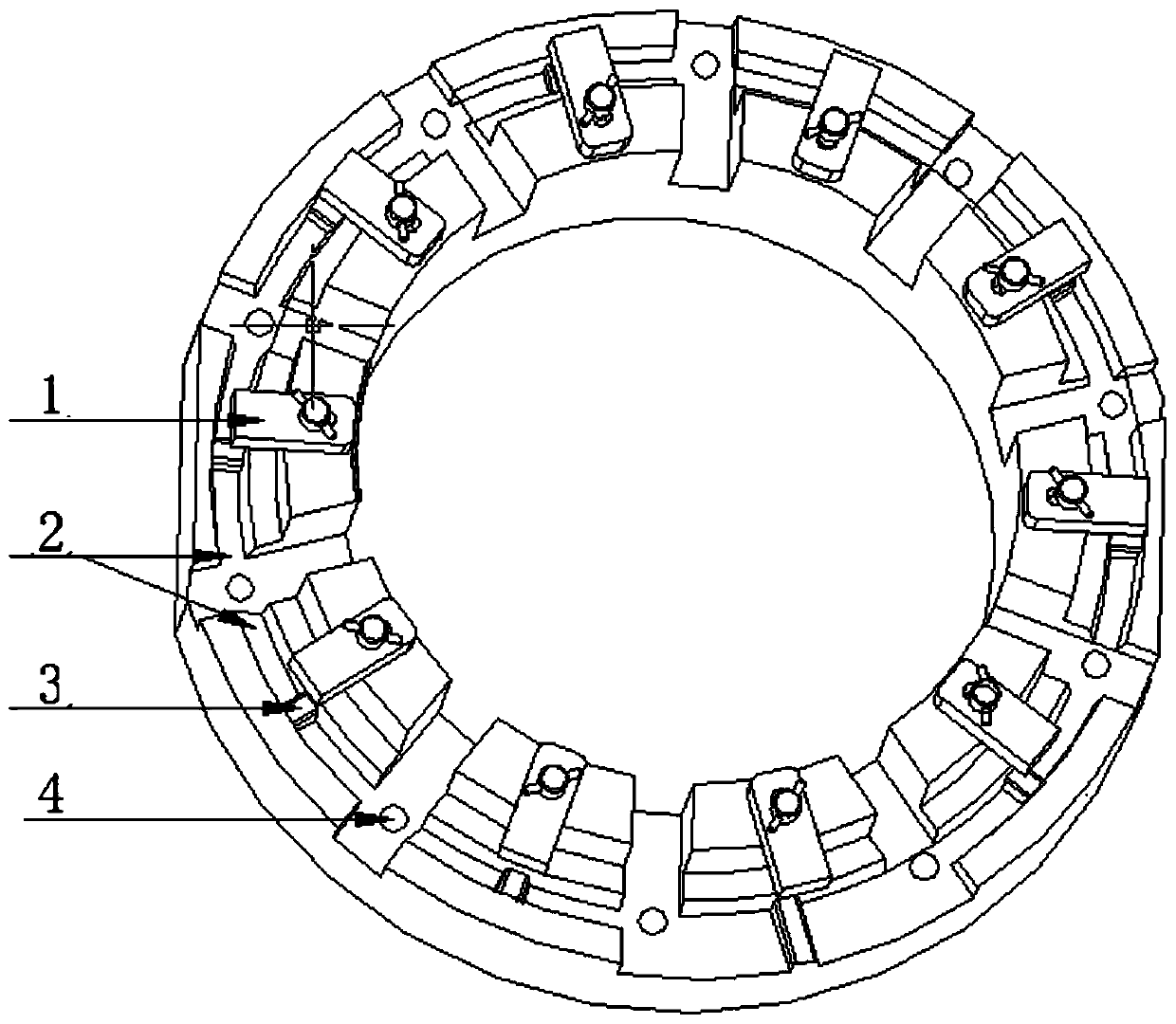

[0018] Such as figure 1 As shown, the present invention provides a kind of splicing method that several core loose blocks are spliced into annular core, comprises the following steps:

[0019] A splicing plate is provided, and a closed annular positioning ring 2 is arranged on the splicing plate. Several limit card slots 3 are arranged on the position ring 2. The number of limit card slots 3 is equal to the number of core blocks, and the limit card The contour of the inner wall of the groove 3 corresponds to the outline of the surface part of the core block one by one. Bonded together, after the adhesive has set, all the core pieces are spliced to form an annular core.

[0020] Further, it is preferred that the raw materials for the adhesive include bauxite and silica sol. Adopting the technical solution of the invention, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com