Bearing large underframe of wagon for transporting U-shaped or box type prefabricated beams

A technology for railway wagons and large underframes, which is applied to railway car body components, underframes, transportation and packaging, etc. It can solve the problem of limited load capacity, inability to fully utilize the role and efficiency of railway transportation equipment, and the carrying capacity of prefabricated beam transport vehicles. Low-level problems, achieve the effect of realizing rotation and translation, and improving bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is further described below in conjunction with specific embodiment, and specific embodiment is the further description of the principle of the present invention, does not limit the present invention in any way, and the identical or similar technology of the present invention all does not exceed the scope of protection of the present invention.

[0032] In conjunction with the accompanying drawings.

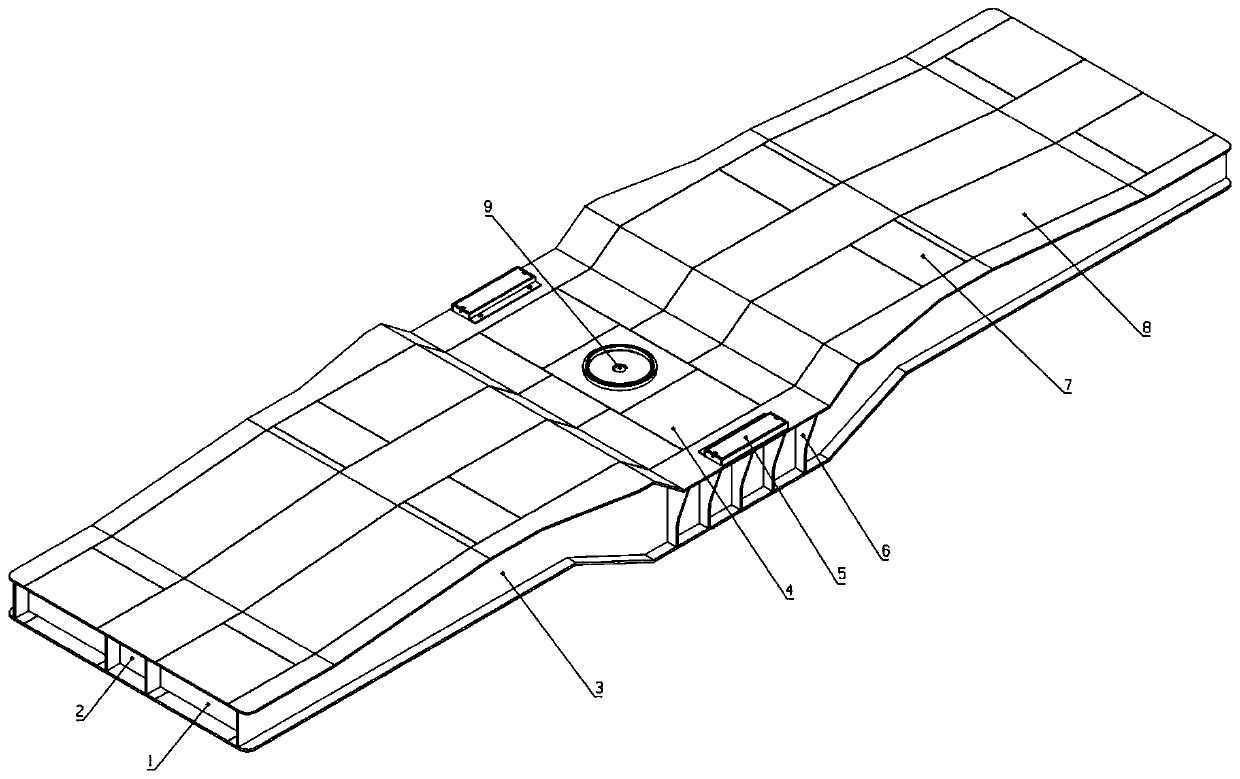

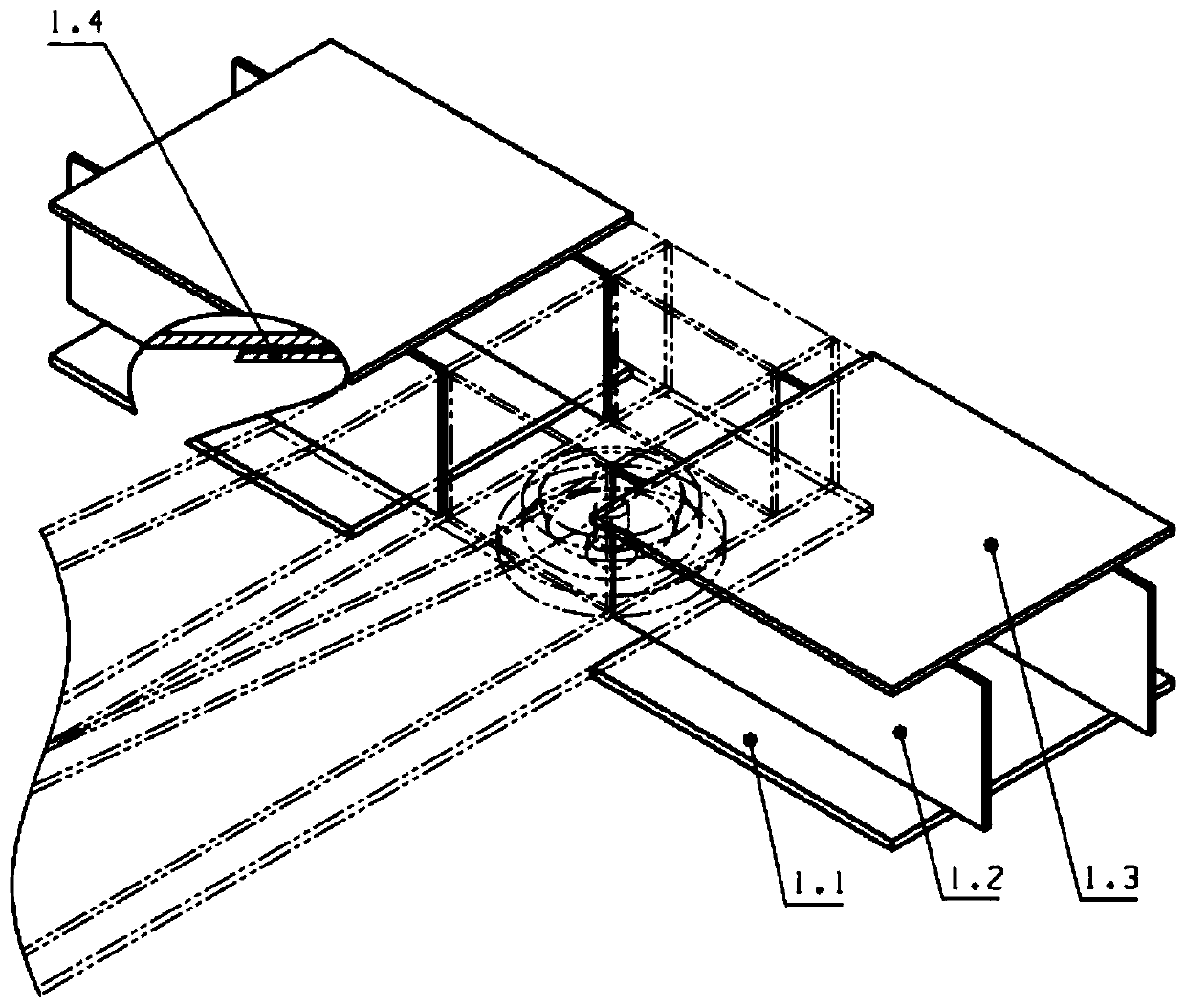

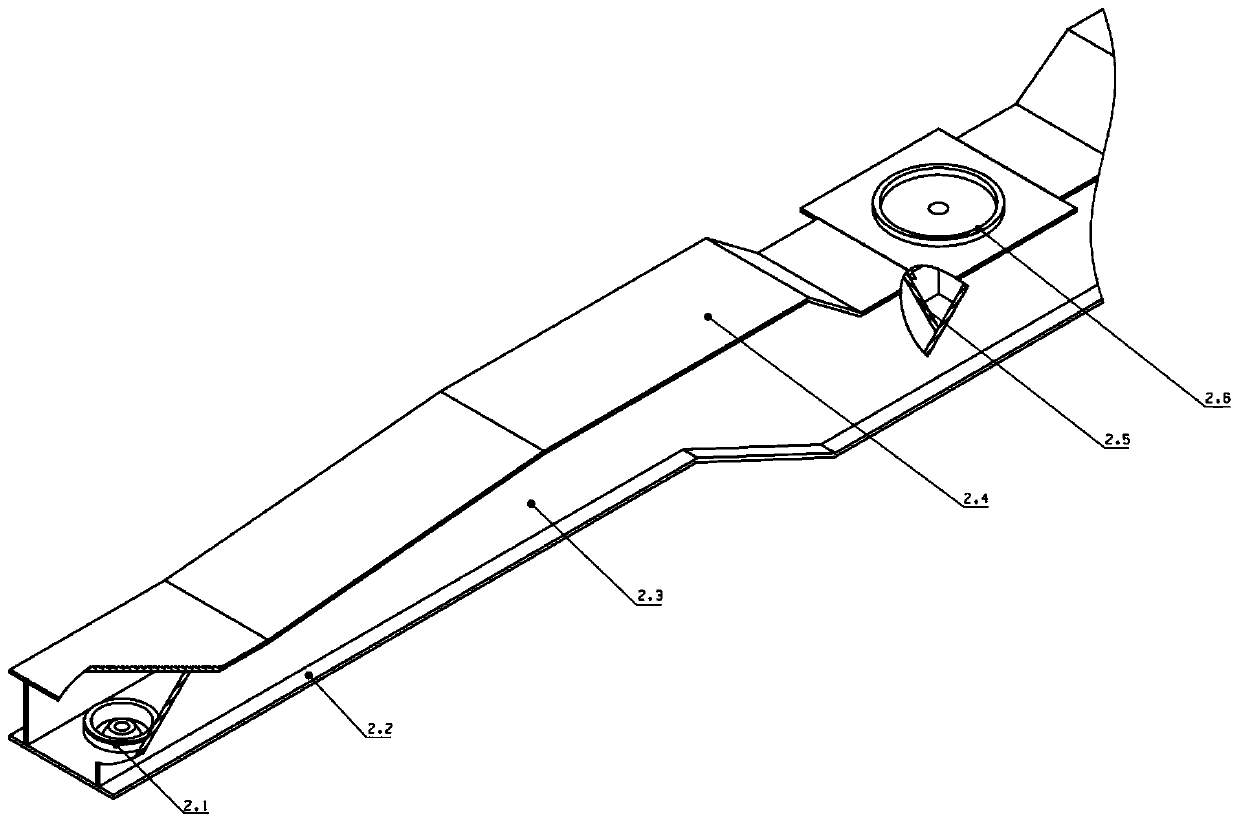

[0033] combine Figure 1 to Figure 6 , the present invention provides a load-bearing underframe for railway freight cars to transport U-shaped or box-shaped prefabricated beams. Composition 5, rib plate 6, crossbeam composition 7, floor 8, center disc wear disc 9.

[0034] The corbel beam composition 1 consists of the lower cover plate 1.1, the web plate 1.2, and the upper cover plate 1.3 welded into a box-shaped closed section structure, which is located at both ends of the large underframe, and its two sides are respectively welded with the middle b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com