A cobalt nitride embedded porous nitrogen-doped graphene material and its preparation method and application

A nitrogen-doped graphene and cobalt nitride technology, applied in the field of electrochemistry, can solve the problems of high cost, limited reserves of precious metal-based catalysts, poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

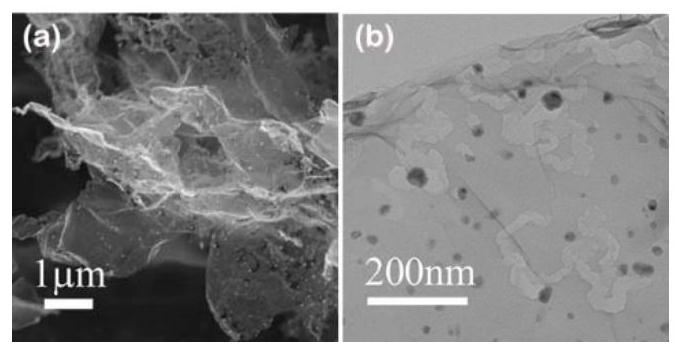

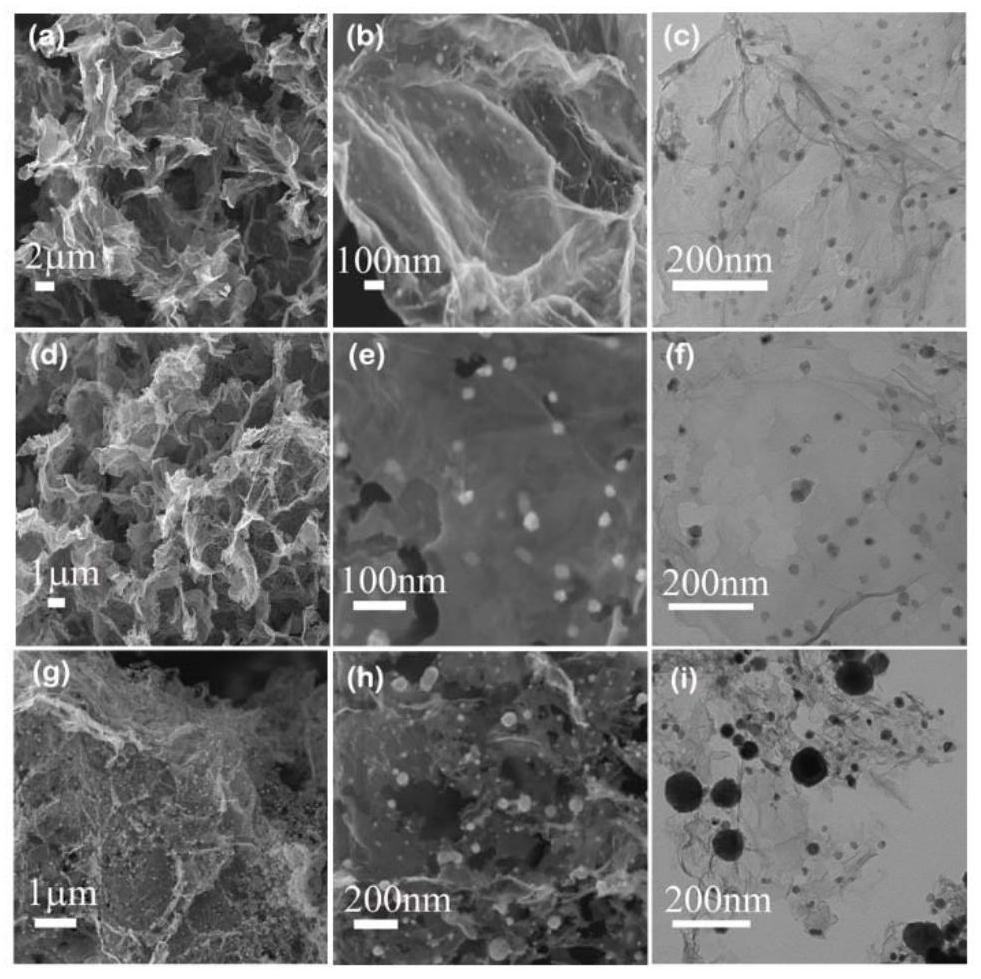

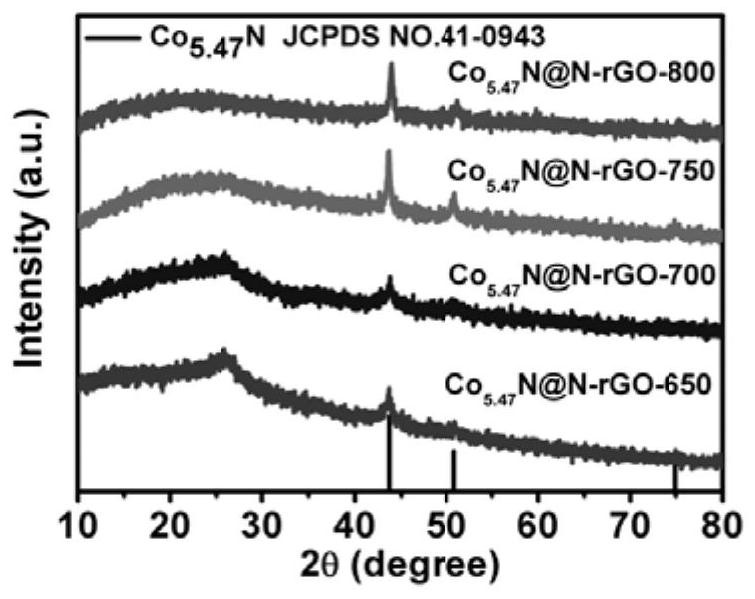

Embodiment 1

[0055] 40mL of GO dispersion (1.5mg mL -1 ) sonicated for 20 minutes, then 2 mmol (0.4982 g) of Co(OAc) was added under vigorous stirring 2 4H 2 O. Subsequently, tannic acid (0.75 g) was dissolved in 10 mL of deionized water and added to the above mixed solution. The resulting suspension was centrifuged, washed with water, flash-frozen with liquid nitrogen and then dried for 12 hours. The obtained samples were loaded into a tube furnace and heated under N 2 : NH 3 In an atmosphere with a ratio of 3:1, it was heated to 650°C at a heating rate of 10°C / min, and pyrolyzed for 1 hour to obtain a sample, which was denoted as Co 5.47 N@N-rGO-650.

Embodiment 2

[0057] 40mL of GO dispersion (1.5mg mL -1 ) sonicated for 20 minutes, then 2 mmol (0.4982 g) of Co(OAc) was added under vigorous stirring 2 4H 2 O. Subsequently, tannic acid (0.75 g) was dissolved in 10 mL of deionized water and added to the above mixed solution. The resulting suspension was centrifuged, washed with water, flash-frozen with liquid nitrogen and then dried for 12 hours. The obtained samples were loaded into a tube furnace and heated under N 2 : NH 3 In an atmosphere with a ratio of 3:1, it was heated to 700°C at a heating rate of 10°C / min, and pyrolyzed for 1 hour to obtain a sample, which was denoted as Co 5.47 N@N-rGO-700.

Embodiment 3

[0059] 40mL of GO dispersion (1.5mg mL -1 ) sonicated for 20 minutes, then added 0.4982 g Co(OAc) under vigorous stirring 2 4H 2 O. Subsequently, tannic acid (0.75 g) was dissolved in 10 mL of deionized water and added to the above mixed solution. The resulting suspension was centrifuged, washed with water, flash-frozen with liquid nitrogen and then dried for 12 hours. The obtained samples were loaded into a tube furnace and heated under N 2 : NH 3 In an atmosphere with a ratio of 3:1, it was heated to 750°C at a heating rate of 10°C / min, and pyrolyzed for 1 hour to obtain a sample, which was denoted as Co 5.47 N@N-rGO-750.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com