Modular method for universal electrode for liquid electrolysis

A technology for electrolysis electrodes and liquid electrodes, which is applied to electrodes, electrolysis processes, electrolysis components, etc., can solve problems such as difficulties in mass production of products, affecting the consistency of electrolytic liquid indicators or effects of electrolysis electrodes, and difficulty in installation of electrolysis electrodes, so as to prevent air bubbles. Poor circulation affects the effect of water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

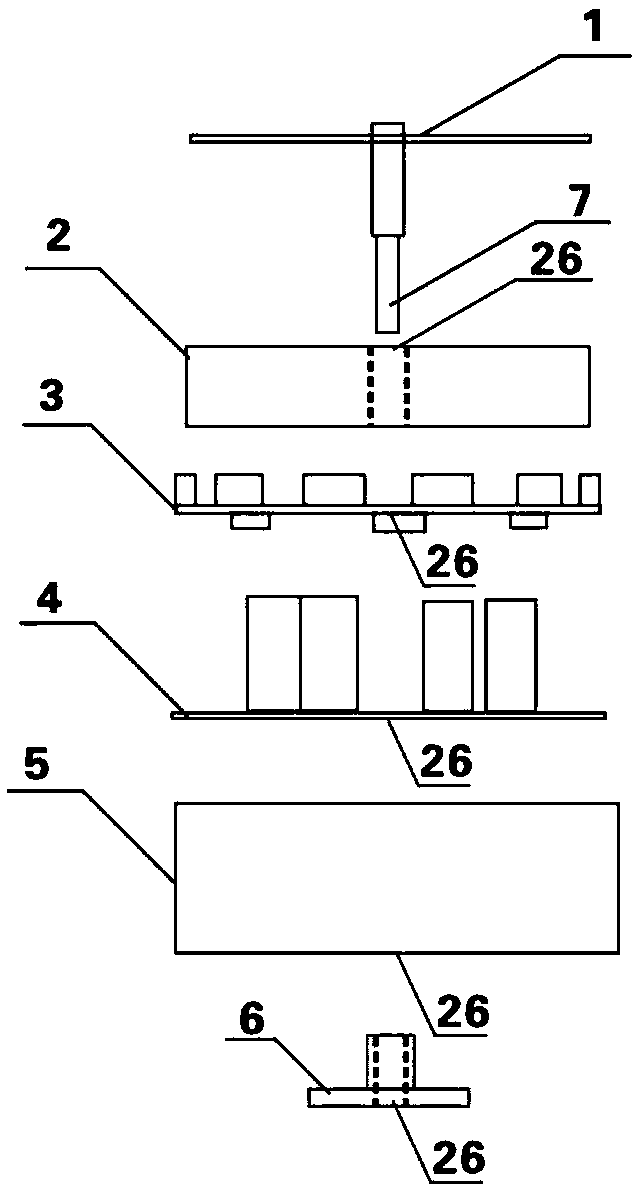

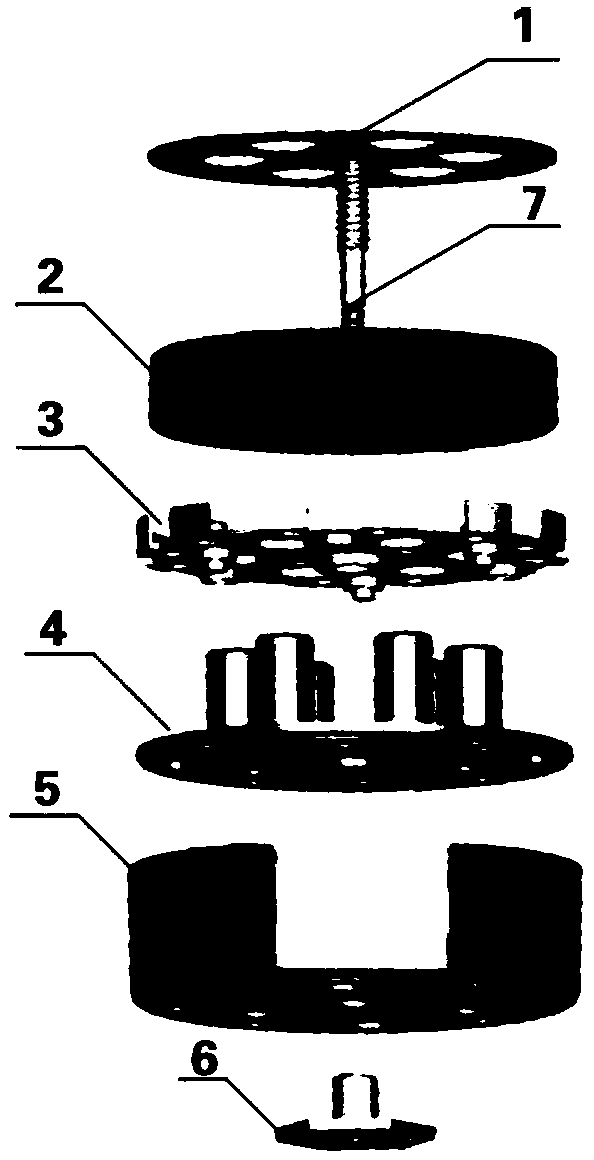

[0025] Such as Figure 1A , Figure 1B , Figure 1C Shown is a general electrolytic liquid electrode modularization method of the present invention, as follows, taking electrolyzed water as an example, Figure 1A It is the front view of Embodiment 1, Figure 1B It is the explosion diagram of embodiment 1, that is, the three-dimensional development diagram of each component of the electrode module, Figure 1C It is the assembly finished product figure of embodiment 1 universal electrolytic liquid electrode module; From Figure 1A , Figure 1B It can be seen that Embodiment 1 includes a module fastening gasket 1 fixed with a screw rod 7, an electrolysis electrode 2, a non-conductive isolation gasket 3 for isolating electrodes 2 and 4 of different polarities, an electrolysis electrode 4, a cylindrical electrode 5, a belt The fastening gasket 6 of the convex ring, one end of the barrel of the cylindrical electrode 5 has a bottom surface and the other end is open; 2 to 6 have mou...

Embodiment 2

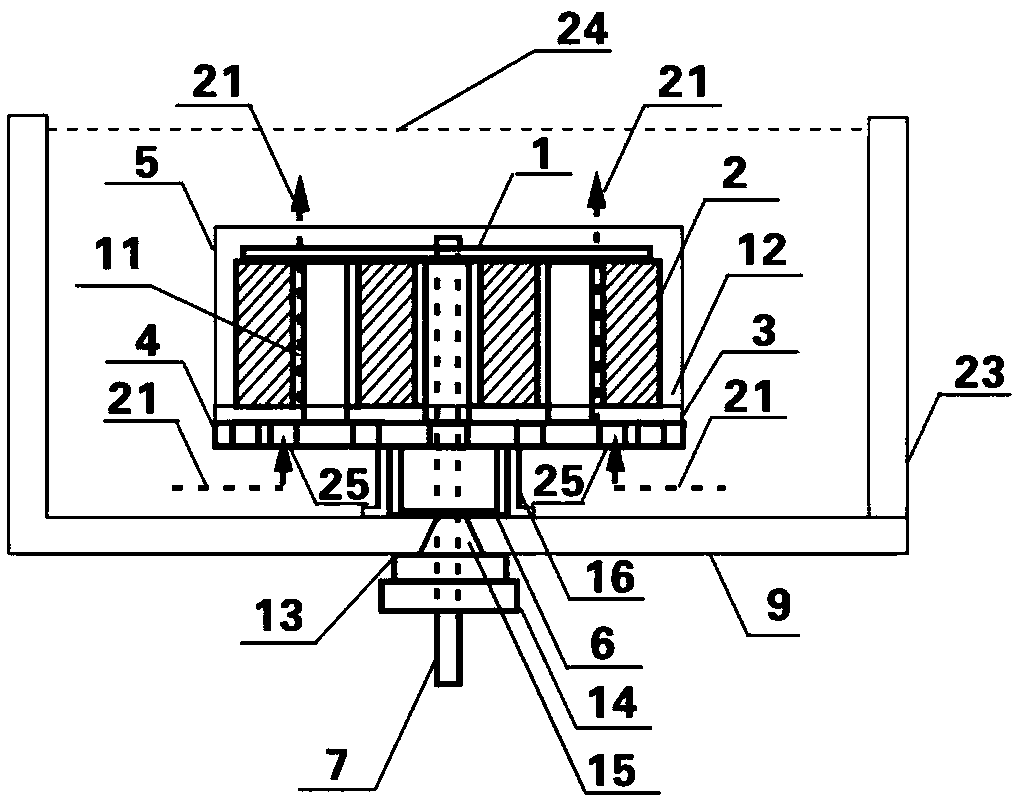

[0029] Such as Figure 2A , Figure 2B The present invention is a general electrolytic liquid electrode modularization method, as follows, taking electrolyzed water as an example, Figure 2A It is the front view of Embodiment 2, Figure 2B It is the assembly finished product diagram of the general electrolytic liquid electrode module of embodiment 2, Figure 2C It is a diagram showing that the second electrode module is installed on the bottom plate of a non-conductive electrolyzer; from Figure 2A , Figure 2B It can be seen that compared with Example 1, only the cylindrical electrode 5 in Example 1 is missing, so there is an electrode gap 12 between the 5 and 2 pie-shaped outer edge sides, and the rest are similar to Example 1. No longer.

[0030] Figure 2C Explain the installation and application method of the electrode module 2 when the bottom plate 9 of the container (electrolyzer) 23 is a non-conductor (such as plastic, glass, ceramics, etc.): the electrode module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com