Shear-resistant and shock-isolation assembly type synchronous variable-position comb teeth-shaped telescopic device

A telescopic device and assembled technology, which is applied to bridge parts, bridges, buildings, etc., can solve the problems of lack of support strength, easy leakage of garbage and dust-proof effectiveness, etc., shorten the construction period, make the construction assembly process simple and convenient, and improve construction benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

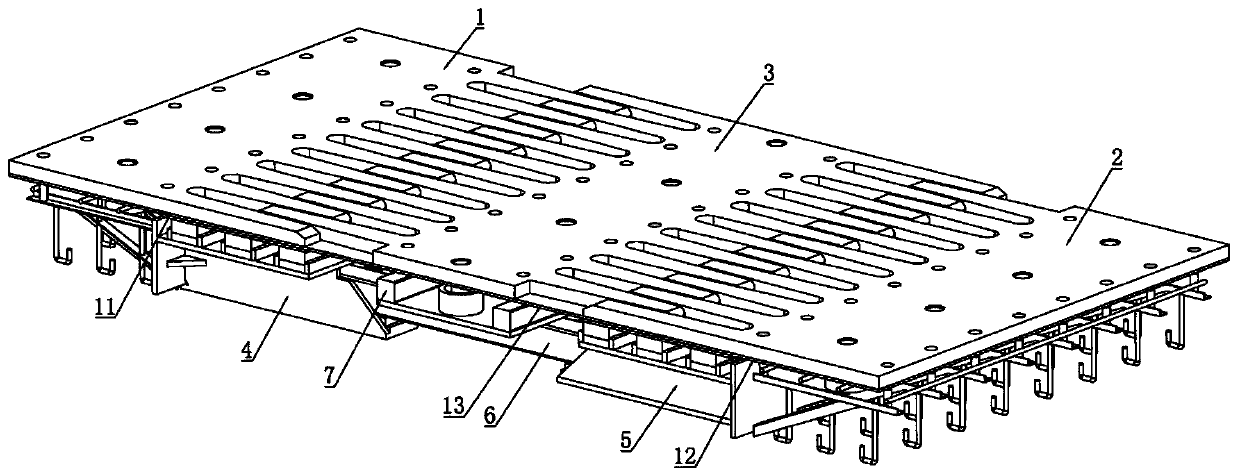

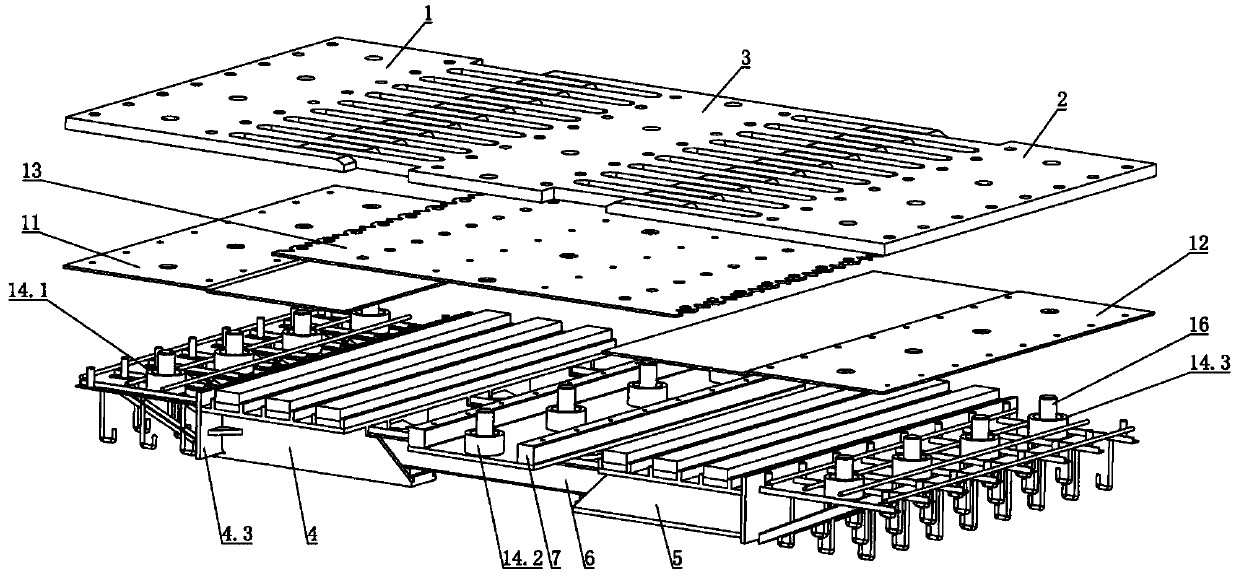

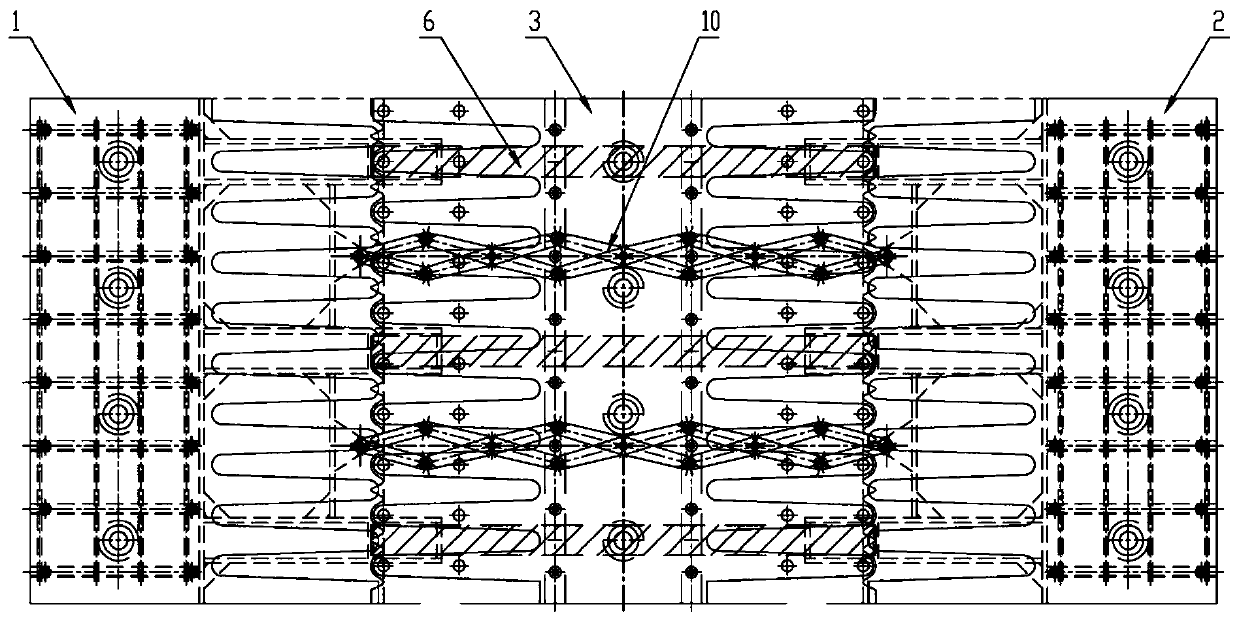

[0039] Such as Figure 1-6 As shown, it is one of the embodiments of the shear-shock-isolation assembled synchronous displacement comb-shaped telescopic device of the present invention. Type structure, including the left and right displacement boxes, hinges, displacement box girders, beams, left, middle and right comb plates fixed at the beam end; It is fixedly connected to the displacement box girder; when the bridge expands and contracts, the middle comb plate is equally displaced relative to the left and right comb plates.

[0040] For the convenience of explaining the components in each drawing, the position and connection relationship between the components, the left and right direction along the vehicle on the bridge is set as the vertical direction, the direction through the pages of the drawings is defined as the horizontal direction, and the vertical direction along the page is defined as the vertical direction.

[0041] refer to Figure 1~Figure 5 , each unit inclu...

Embodiment 2

[0049] Such as Figure 7 and 8 As shown, it is another embodiment of the shear-shock-isolation assembled synchronous displacement comb-shaped expansion device of the present invention, which is a structural unit suitable for medium and large spans (80mm≤expansion amount≤960mm). In the figure, The left panel 21 on the left and the right panel 22 on the right are both comb-shaped, and the left panel 21 and the right panel 22 have an asymmetric structure with respect to the expansion joint, and two rows of counterbore holes are respectively processed on the left panel 21 and the right panel 22 , A long hole nut fixedly connected with the beam end anchorage member is arranged under the counterbore, and a high-strength bolt 17 is installed between the counterbore and the long hole nut. At least three evenly distributed through holes are processed in the transverse direction between the two rows of counterbores, and the shear pins 16 are fixedly connected in the through holes, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com