Integrated composite wall panel of thermal insulation structure

A technology for thermal insulation wall panels and wall panels, which is applied in thermal insulation, walls, building components, etc., can solve the problems of complex construction procedures, building volume ratio, actual use area impact, and increase in thickness of concrete bottom plates, etc., to optimize the prefabrication process and construction. technology, beneficial to effective application and promotion, and the effect of meeting the strength requirements of wall panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

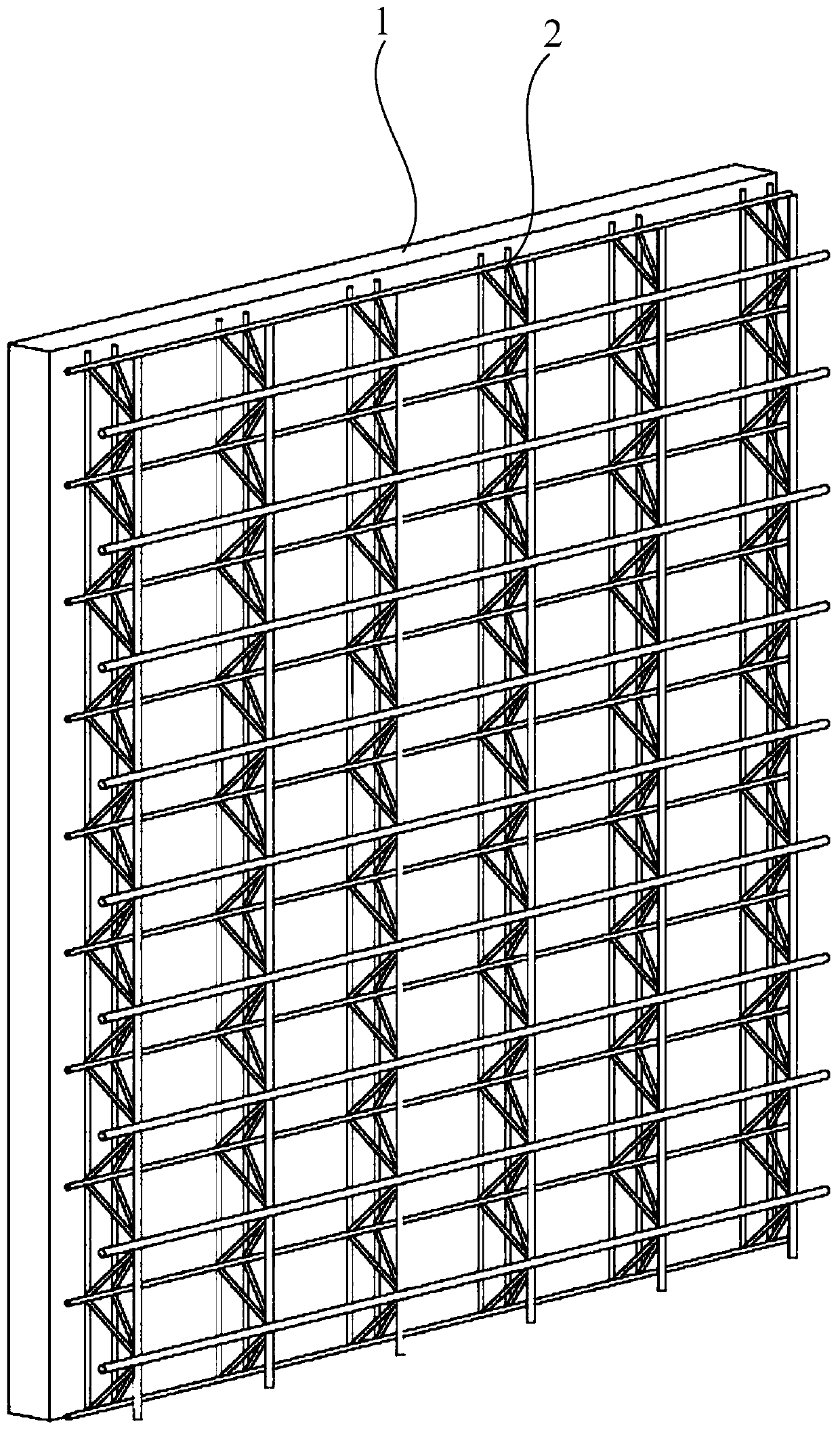

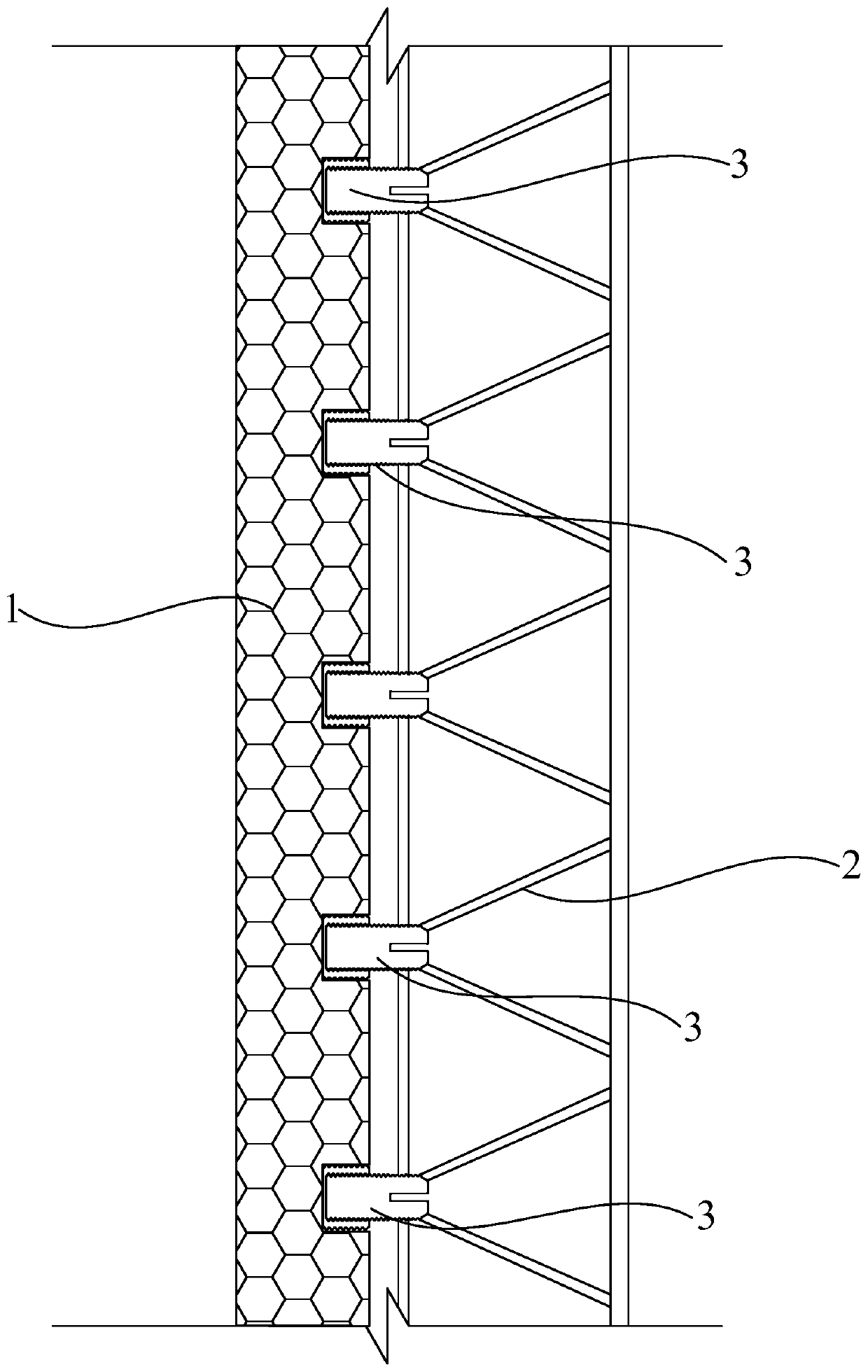

[0046] Such as Figure 1 to Figure 5 As shown, this embodiment discloses an integrated laminated wallboard with thermal insulation structure. The two ends of the insulation wallboard body 1 and the steel truss 2 are respectively connected, and the material of the insulation wallboard body 1 is an organic-inorganic composite material with a fireproof performance reaching A2 level.

[0047] The material of the thermal insulation wall panel body 1 is an organic-inorganic composite material with a fireproof performance reaching A2 level, and the thermal insulation wall panel body 1 adopts an organic-inorganic composite thermal insulation material that can meet the wall panel strength requirements of the laminated wall to replace the prefabricated thermal insulation material in the prior art. The concrete wall panel effectively connects the thermal insulation wall panel body 1 and the steel bar truss 2 through the connecting piece 3, while satisfying the thermal insulation performa...

Embodiment 2

[0060] Such as Figure 6 , Figure 7 and Figure 8 As shown, the same parts of the laminated wallboard with integrated thermal insulation structure in Embodiment 2 and the laminated wallboard with integrated thermal insulation structure in Embodiment 1 will not be repeated, and only the differences will be described. The difference is that the connecting piece 3 has an integrated structure, and the connecting piece 3 passes through the insulation wall panel body 1 and is connected with the steel bar truss 2 . The connecting piece 3 is made by one-piece molding, which is convenient to manufacture and low in cost. When in use, the connecting piece 3 will pass through the insulation wall panel body 1 and connect with the steel bar truss 2, so as to realize the effective connection between the insulation wall panel body 1 and the steel bar truss 2, and the connection is very convenient.

[0061] The connector 3 includes an insertion portion 34 and an abutment portion 33 , the a...

Embodiment 3

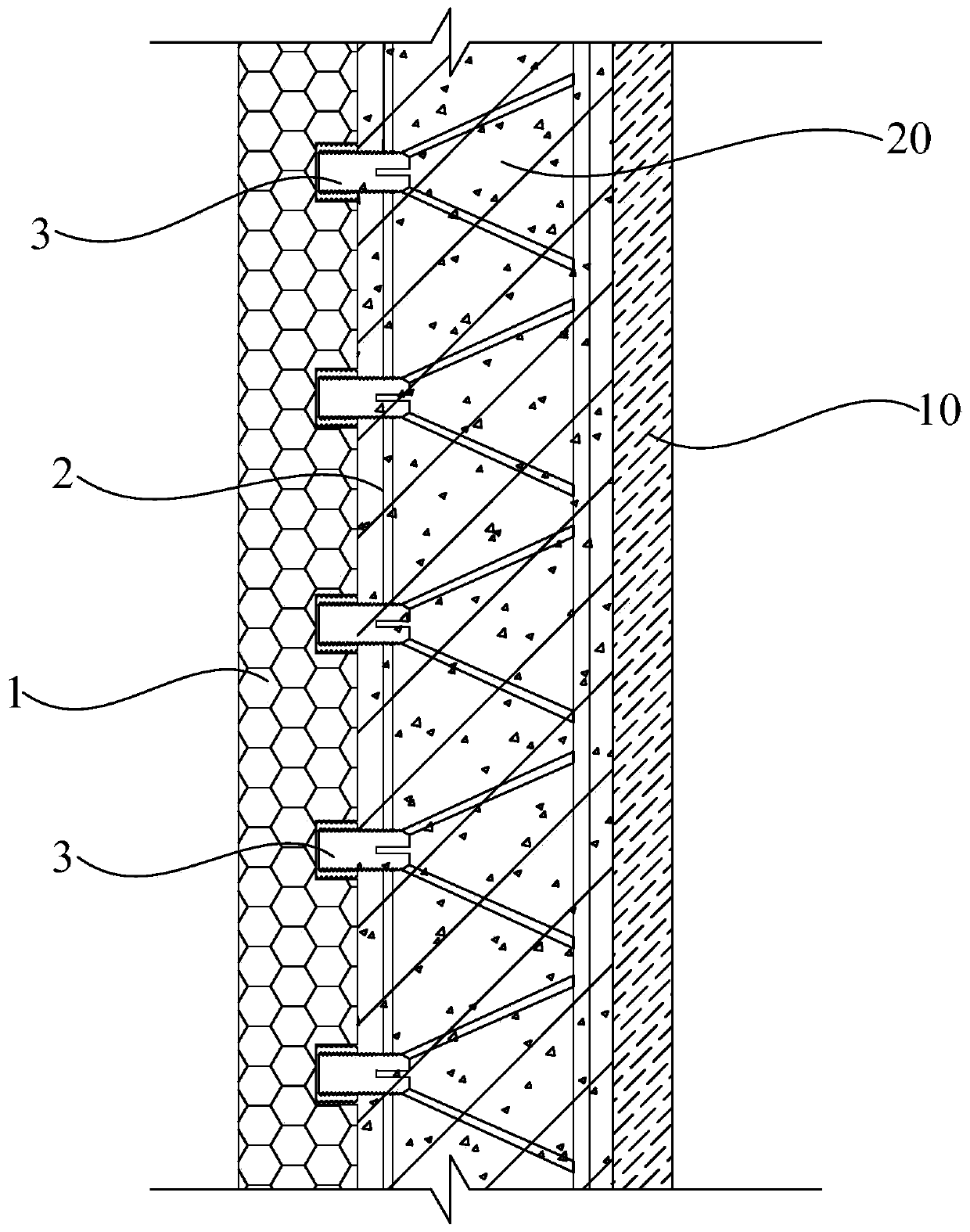

[0068] Such as Figure 9 , Figure 10 and Figure 11 As shown, the same parts of the laminated wallboard with integrated thermal insulation structure in Embodiment 3 and the laminated wallboard with integrated thermal insulation structure in Embodiment 1 will not be repeated, and only the differences will be described. The difference is that the thermal insulation structure integrated laminated wallboard in Example 1 is in the form of a single laminated wallboard, and the thermal insulation structure integrated laminated wallboard in this embodiment is in the form of a double laminated wallboard. The structurally integrated laminated wall panel also includes an additional thermal insulation wall panel body 4, and the two sides of the steel bar truss 2 are connected to the additional thermal insulation wall panel body 4 and the thermal insulation wall panel body 1 through several connectors 3 respectively. In order to meet the requirements of architectural design, by setting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com