Mechanical garage frame assembled on site mainly using reinforced concrete prefabricated parts

A technology of reinforced concrete and mechanical garage, applied in the field of mechanical garage frame, can solve the problems such as the garage cannot be widely used and the steel is easy to rust, and achieves the effect of reducing the maintenance workload, reducing the production cost and preventing the steel from rusting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with embodiment the present invention is described in further detail.

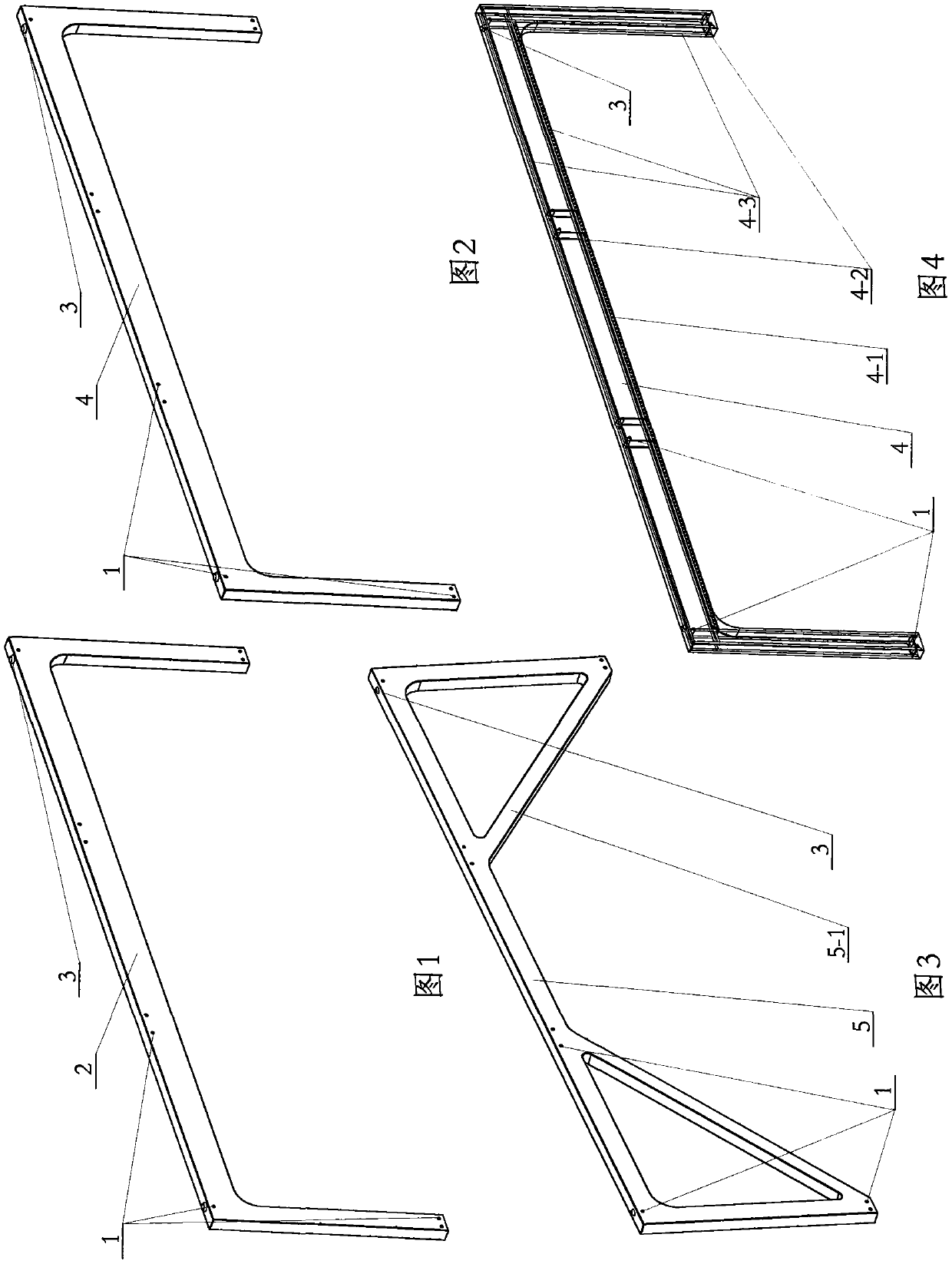

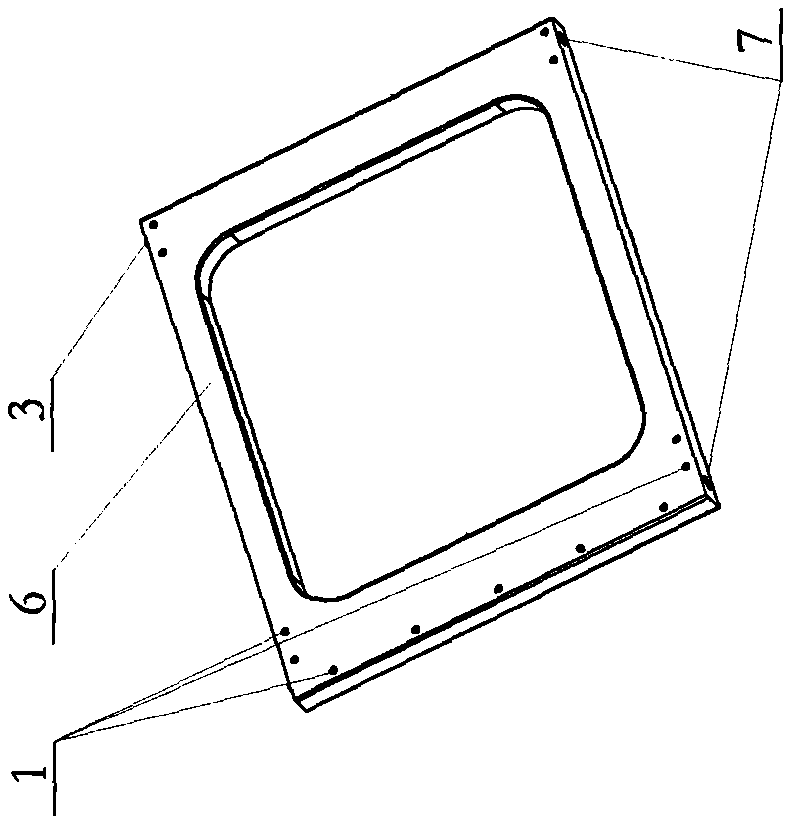

[0034] Refer to attached Figure 15 : Embodiment 1 is a group of (3 upper, 2 lower, 5 parking spaces) two-floor lifting and lateral movement frames, the front is the door frame part-A type (2), the back is the door frame part-C type (5), 4 beam parts (11) 2 end upper sides rest on them, and the lower side is embedded in the inner file of door frame parts-A type (2) and door frame parts-C type (5). The bolt group (18) passes through the casing (1) on the concrete prefabricated part and the hole (14) on the connecting member-A type (13) and is fixed to each other. The following of door frame parts-A type (2), door frame parts-C type (5) are fixed with the ground by connecting member-B type (15) and expansion bolts (19). Mutually fix each other by connecting member-D type (17) and bolt group (18).

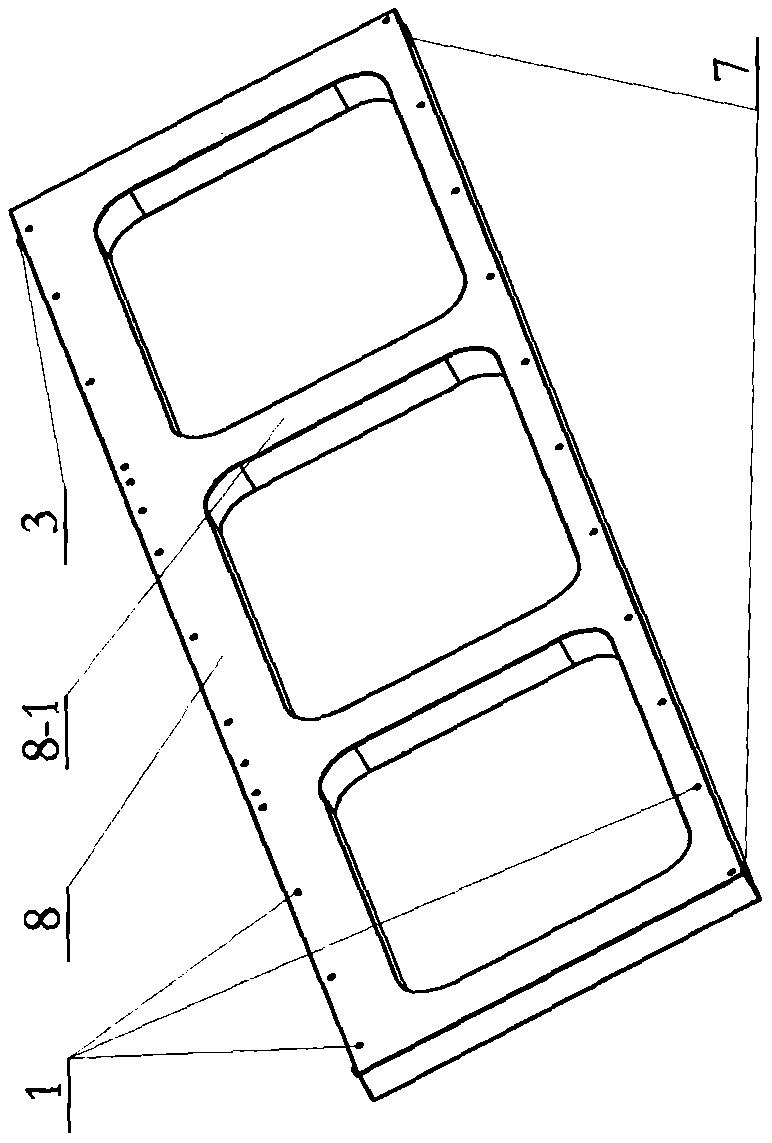

[0035] Refer to attached Figure 16 Embodiment 2 is a group of (3, 8, and 11 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com