An automatic rod feeding device for a rock bolter used in coal mines

A technology of bolt drilling rig and bolt, which is applied in the installation of bolts, drill pipes, drill pipes, etc., can solve the problems of low operation efficiency, long roadway support process and increased roadway collapse risk, etc., so as to reduce the collapse risk and shorten the Support process time, realize the effect of automatic operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with embodiment and with reference to Figure 1 to Figure 9 The present invention is further described.

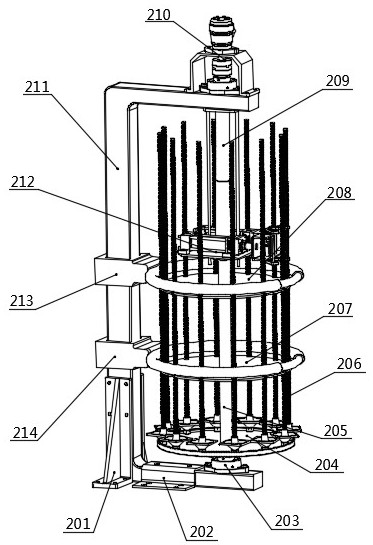

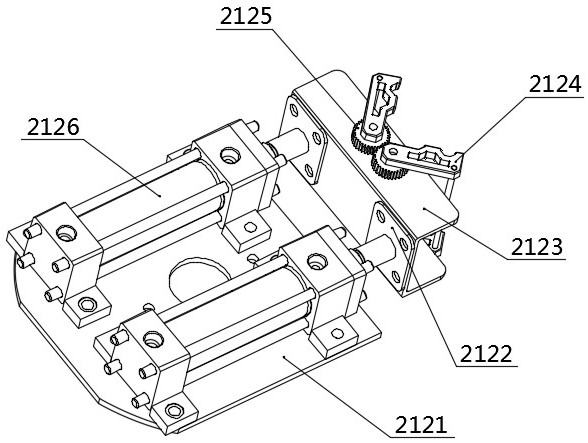

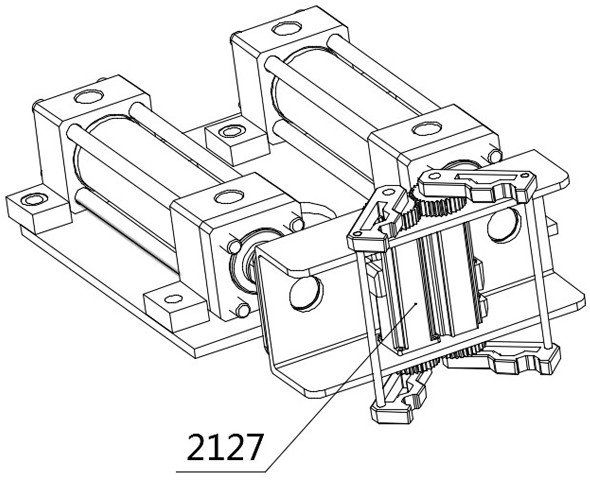

[0025] This embodiment provides an automatic rod feeding device for a rock bolter used in coal mines, which includes a fixed angle seat 201, a fixed seat 202, a flange bearing 203, a bolt support plate 204, a rotating central shaft 205, a bolt 206, Anchor rod indexing plate 1 207, anchor rod indexing plate 2 208, anchor rod grabbing manipulator fixing sleeve 209, hydraulic drive device 210, anchor rod storage bracket 211, anchor rod grabbing manipulator 212, anchor rod automatic retaining ring 1 213, Anchor rod automatic retaining ring 2 214; Anchor rod storehouse bracket 211 includes vertical arm 2111, cross arm 1 2112 and cross arm 2 2113, cross arm 1 2112 and cross arm 2 2113 are respectively vertically fixed to the two ends of vertical arm 2111 The vertical arm 2111, cross arm one 2112 and cross arm two 2113 are all rectangular in cross sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com