Method suitable for online evaluation of global operation condition in continuous production process

A technology of production process and operation status, applied in the direction of program control, comprehensive factory control, comprehensive factory control, etc., to achieve the effect of accurate evaluation, accurate global operation status evaluation results, and elimination of deviations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

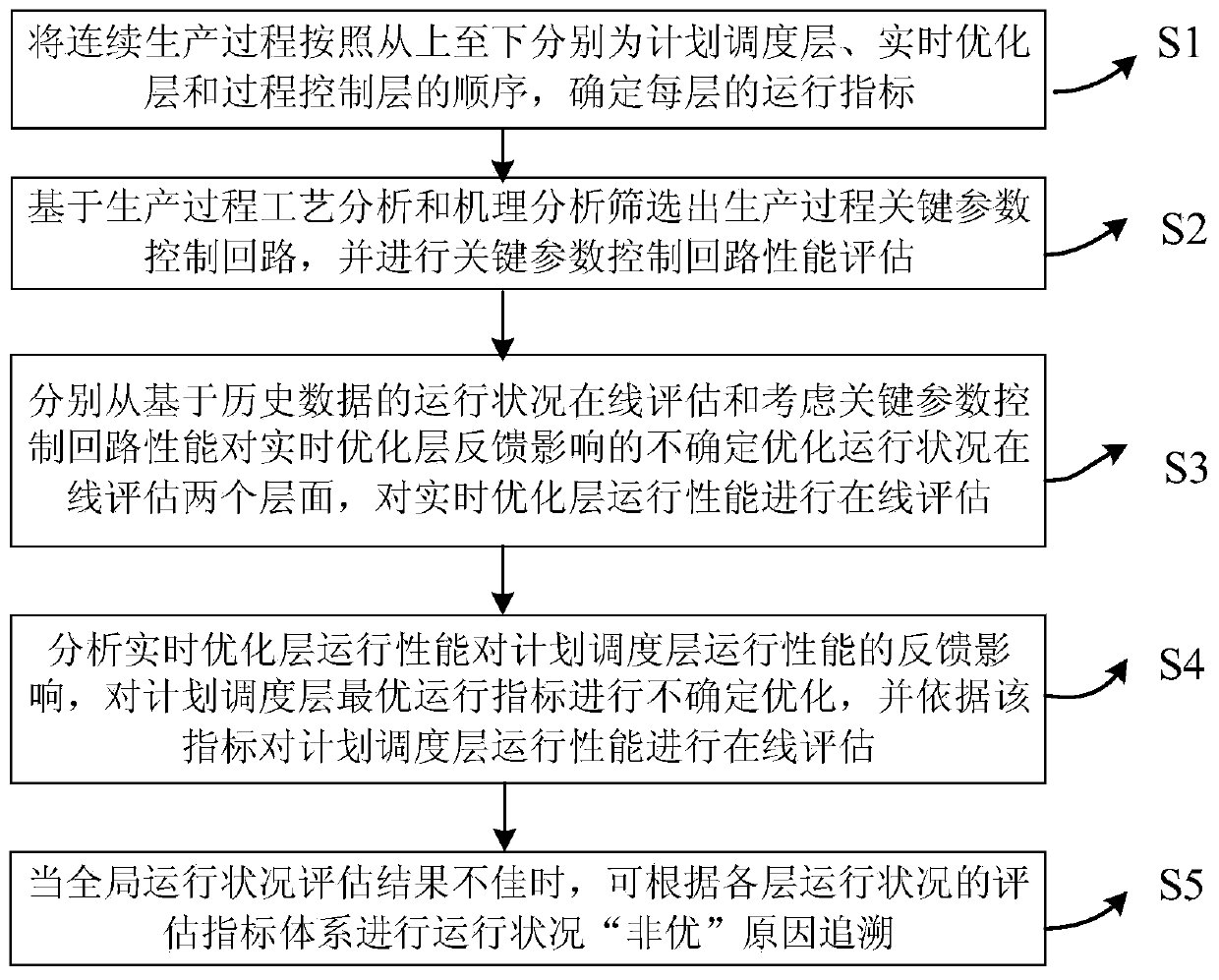

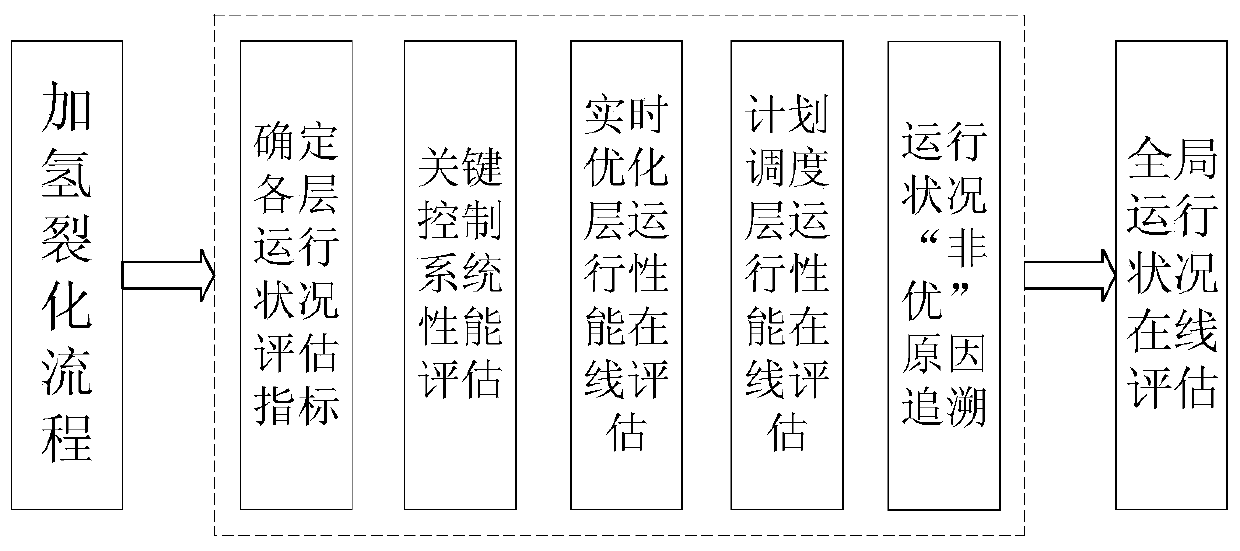

[0066] Taking the hydrocracking process of an oil refinery in my country as an example, combined with figure 1 , figure 2 Shown, a kind of method that is applicable to the continuous production process global operating state online evaluation that proposes in the present invention is described in detail as follows:

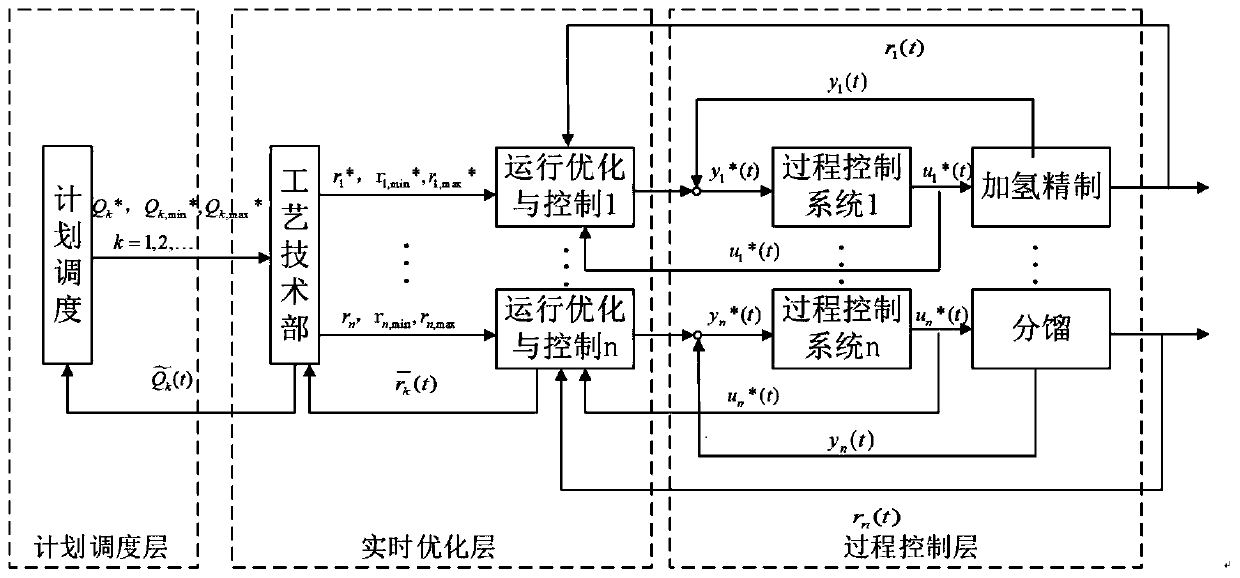

[0067] The first step is to divide the continuous production process of the hydrocracking process into planning and scheduling layer, real-time optimization layer and process control layer from top to bottom, and determine the operation indicators of each layer; the process control layer, real-time optimization layer and planning and scheduling layer There is a bottom-up feedback relationship. The whole process of hydrocracking process operation optimization and control is as follows: image 3 As shown, it mainly involves three levels: planning and scheduling layer, real-time optimization layer and process control layer. The planning and scheduling layer is ba...

Embodiment 2

[0114] Taking the residual oil hydrogenation process of a refinery in my country as an example, a method for online evaluation of the global operating status of a continuous production process proposed in the present invention is described in detail as follows:

[0115] In the first step, the residue hydrogenation process is divided into planning and scheduling layer, real-time optimization layer and process control layer from top to bottom, and the operation indicators of each layer are determined; there are Bottom-up feedback relationship. The whole process of operation optimization and control of residual oil hydrogenation process is as follows: Figure 12 As shown, it mainly involves three levels: planning and scheduling layer, real-time optimization layer and process control layer. The planning and scheduling layer is based on the target of monthly or quarterly comprehensive production indicators (light oil yield, energy consumption per unit energy factor, etc.) Perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com