Large-section EPR insulated direct-current flexible cable for wind power and production process thereof

A production process and large cross-section technology, applied in the direction of insulated cables, insulated conductors, organic insulators, etc., can solve problems such as inability to meet high-power transmission, and achieve excellent tear resistance, large carrying capacity, and safe laying and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

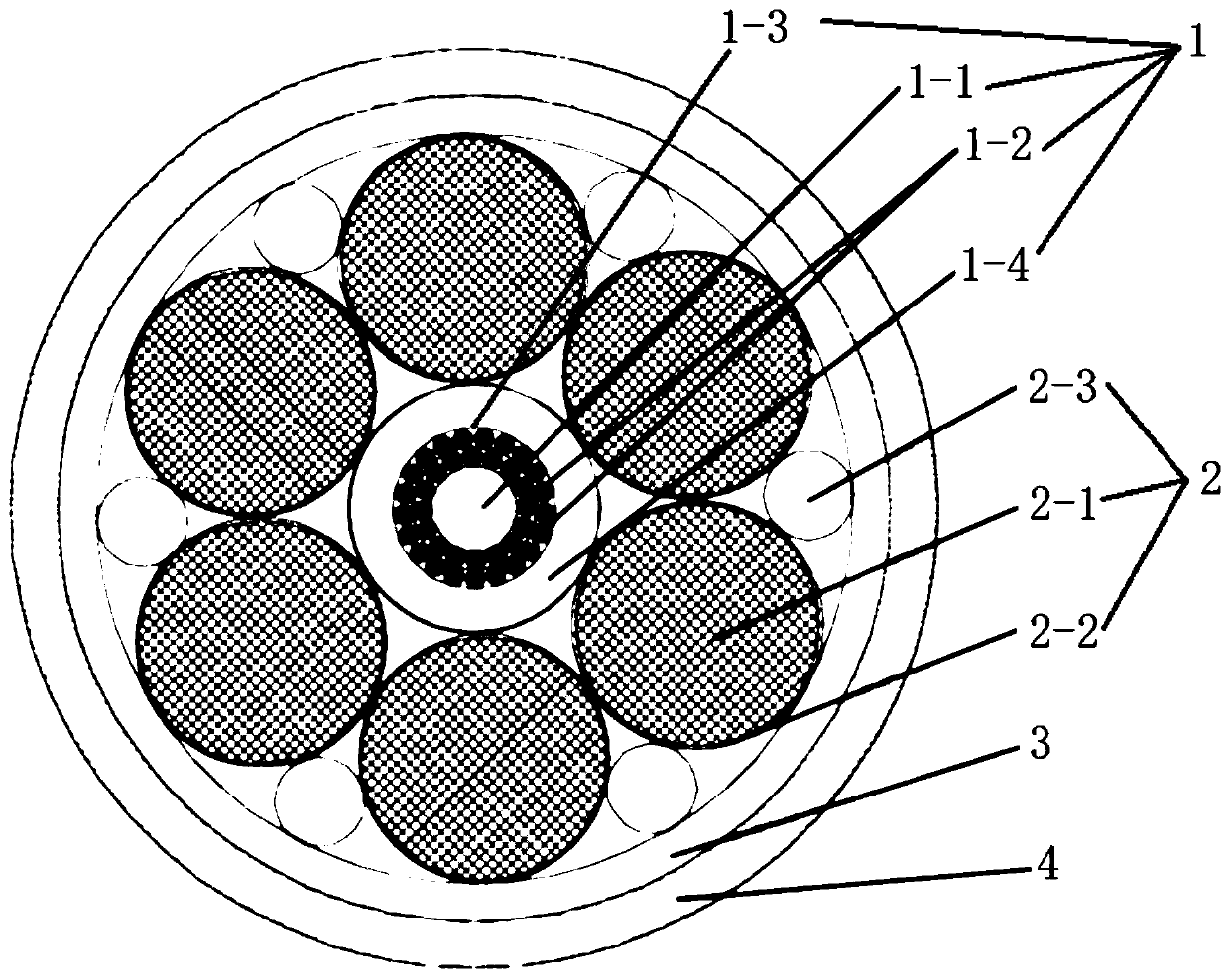

[0035] See figure 1 , The large-section EPR insulated DC flexible cable for wind power in this embodiment includes a central core 1, a main conductor 2, a main insulating layer 3 and an outer sheath 4 from the inside to the outside.

[0036] The central core 1 includes a central insulating filling bar 1-1, a central conductor 1-2, a central wrapping tape 1-3 and a central insulating layer 1-4 from inside to outside. The center wrapping belt 1-3 adopts semi-conductive nylon belt. The central conductor 1-2 is a soft structural aluminum conductor. The covering rate of the center wrapping tape 1-3 is 40%-50%.

[0037] The main conductor 2 includes a plurality of sub-item conductors 2-1 twisted and wrapped around the center line core 1, semi-conductive strips 2-2 wrapped around the outside of the sub-item conductors 2-1, and filled in adjacent sub-item conductors 2 -1 Semi-conductive filler strips 2-3 in the external gap. Subitem conductor 2-1 is a soft structural aluminum cond...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com