Cleaning, fixation and drying device and drying method thereof

A technology for drying equipment and cleaning equipment, applied in the field of drying rooms, can solve the problems of unusability, high labor and material cost, low work efficiency, etc., and achieve the effects of reasonable structure, high work efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

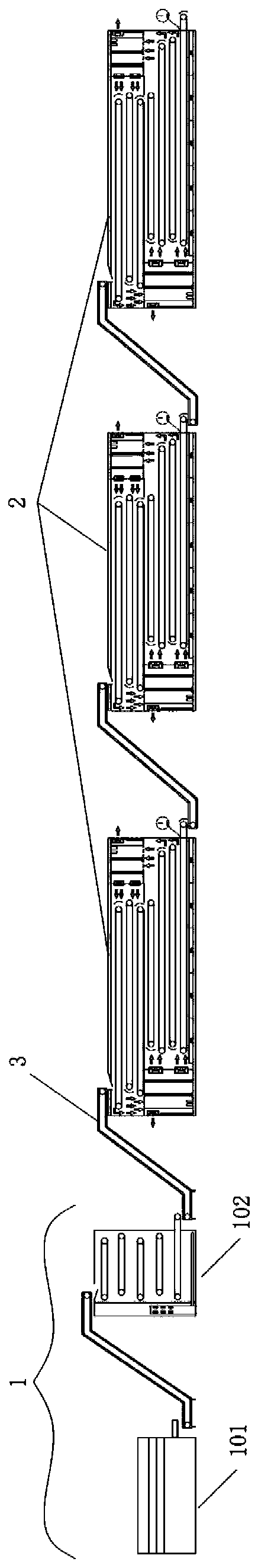

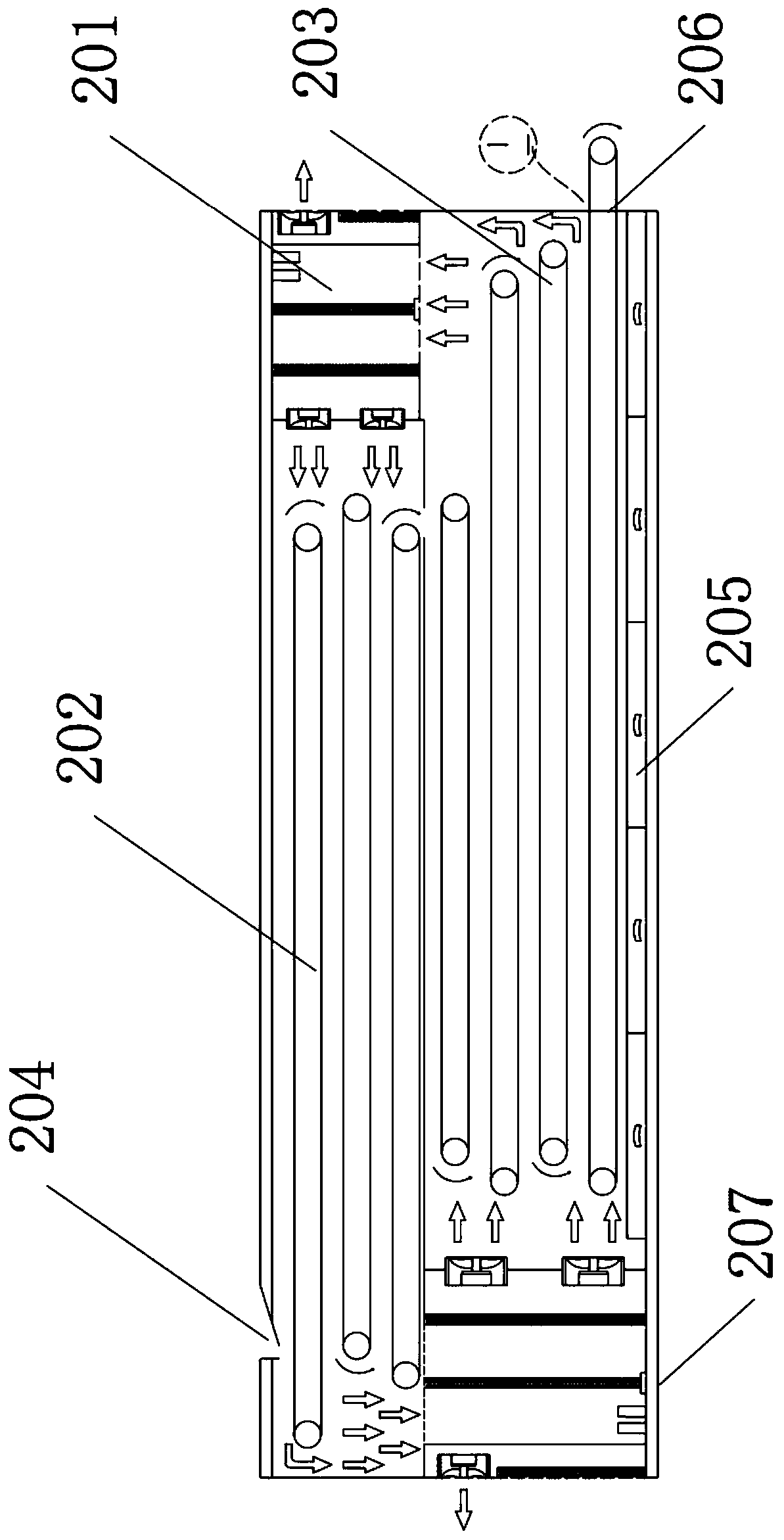

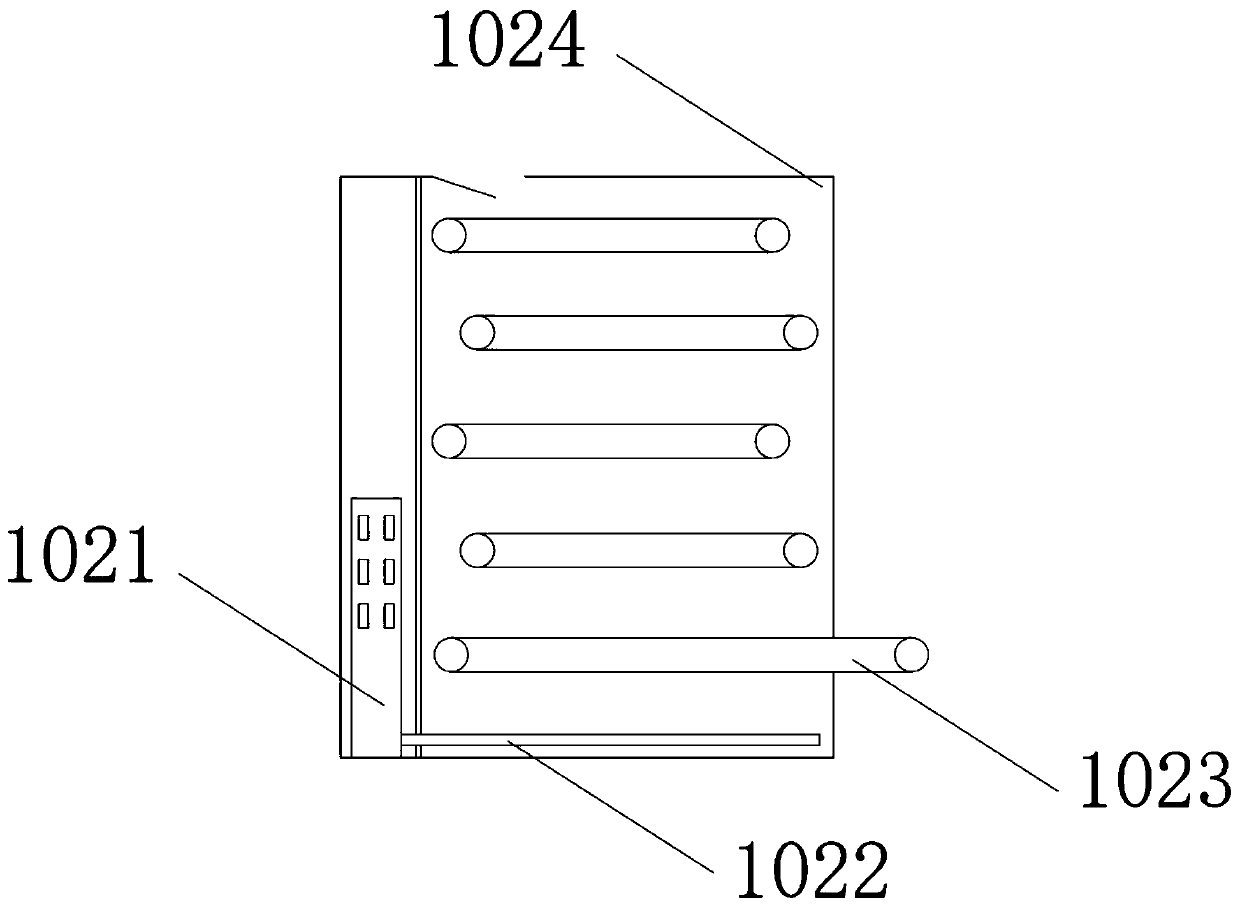

[0035] Embodiment 1: as Figure 1-5 As shown, a cleaning, de-enzyming and drying equipment includes a pre-processing equipment 1, a drying unit 2 and a material hoist 3, wherein: the pre-processing equipment 1 includes a cleaning equipment 101 and a de-enzyming equipment 102; the cleaning equipment 101 is an automatic conveyor belt type material Cleaning machine; there are three drying units 2, which are arranged in a straight line; the drying unit 2 is a room with drying equipment and conveying equipment inside; the material hoist 3 includes a material hoist for feeding and a turnover material hoist ; The quantity of the feeding material hoist is one; the quantity of the turnover material hoist is two; Unit 2 is assembled through the material hoist; the outlet of the pre-processing equipment 1 is located directly above the entrance of the material hoist; the three drying units 2 are equipped in turn through two turnover material hoists; the turnover material hoist The materi...

Embodiment 2

[0052] Embodiment 2: as Figure 1-5 As shown, a kind of cleaning and drying equipment includes preprocessing equipment 1, drying unit 2 and material hoist 3, wherein: preprocessing equipment 1 is cleaning equipment 101; cleaning equipment 101 is an automatic conveyor belt type material cleaning machine; drying There are three dry units 2, which are arranged in a straight line; the drying unit 2 is a room with drying equipment and conveying equipment inside; the material hoist 3 includes a feeding material hoist and a turnover material hoist; The number of elevators is one; the number of turnover material elevators is two; the pre-processing equipment 1 is equipped with the front-end drying unit 2 among several drying units 2; the pre-processing equipment 1 and the drying unit 2 pass through the upper The material hoist is assembled; the outlet of the pre-processing equipment 1 is located directly above the inlet of the material hoist; the three drying units 2 are assembled in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com