An organic waste gas treatment device and method

A technology for organic waste gas and treatment equipment, which is applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of no pretreatment water washing reactor, complicated production process, and shortened service life, so as to improve the efficiency of photocatalytic oxidation. Efficiency, improvement of degradation effect, and compact structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

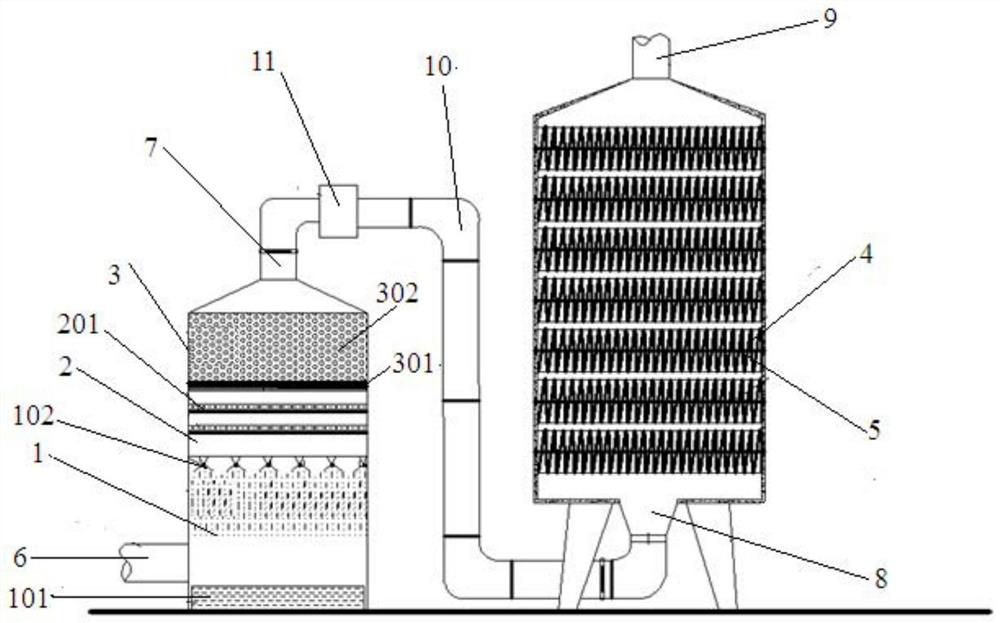

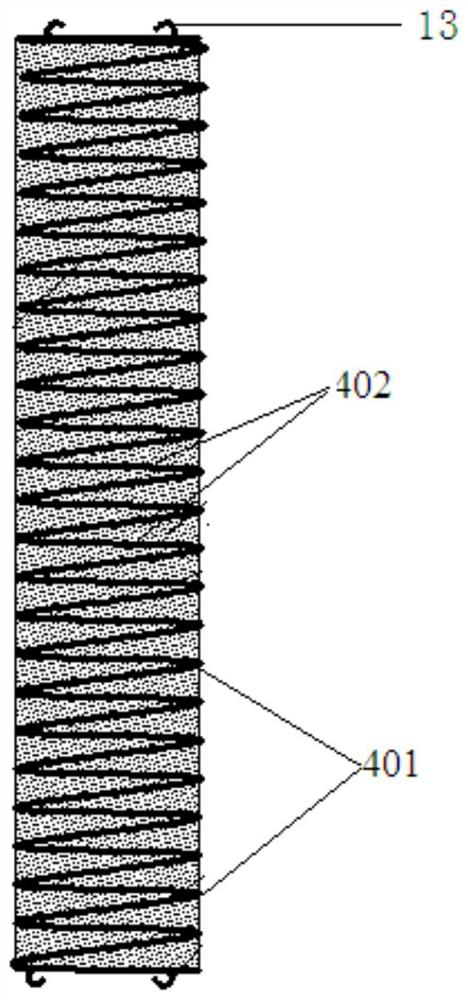

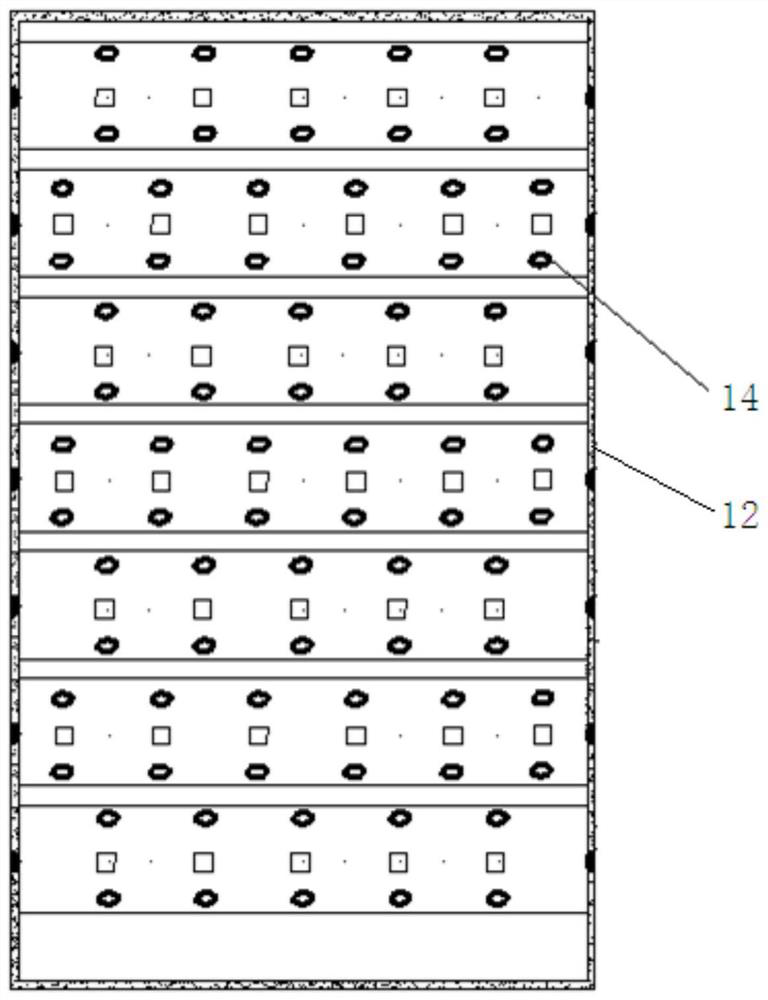

[0050] Such as figure 1 , figure 2 with image 3 As shown, an organic waste gas treatment device includes a pretreatment water washing reactor and a photocatalytic reactor, and the pretreatment water washing reactor is sequentially provided with an atomizer 1, a scrubber 2 and a dehydration demister 3; The bottom and top of the device 1 are respectively provided with a water tank 101 and several atomizing nozzles 102; the scrubber 2 includes a number of washing layers 201 arranged in parallel, and the washing layer 201 uses stainless steel wire mesh and a waterproof and breathable membrane as the supporting surface, and ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap