High-strength composite material raw material multi-stage mixing apparatus and material mixing method thereof

A composite material and mixing device technology, applied in chemical instruments and methods, mixers, transportation and packaging, etc., can solve the problems affecting the quality of fiber composite materials, difficult to eliminate, etc., to make full use of space, reduce air volume, mix full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

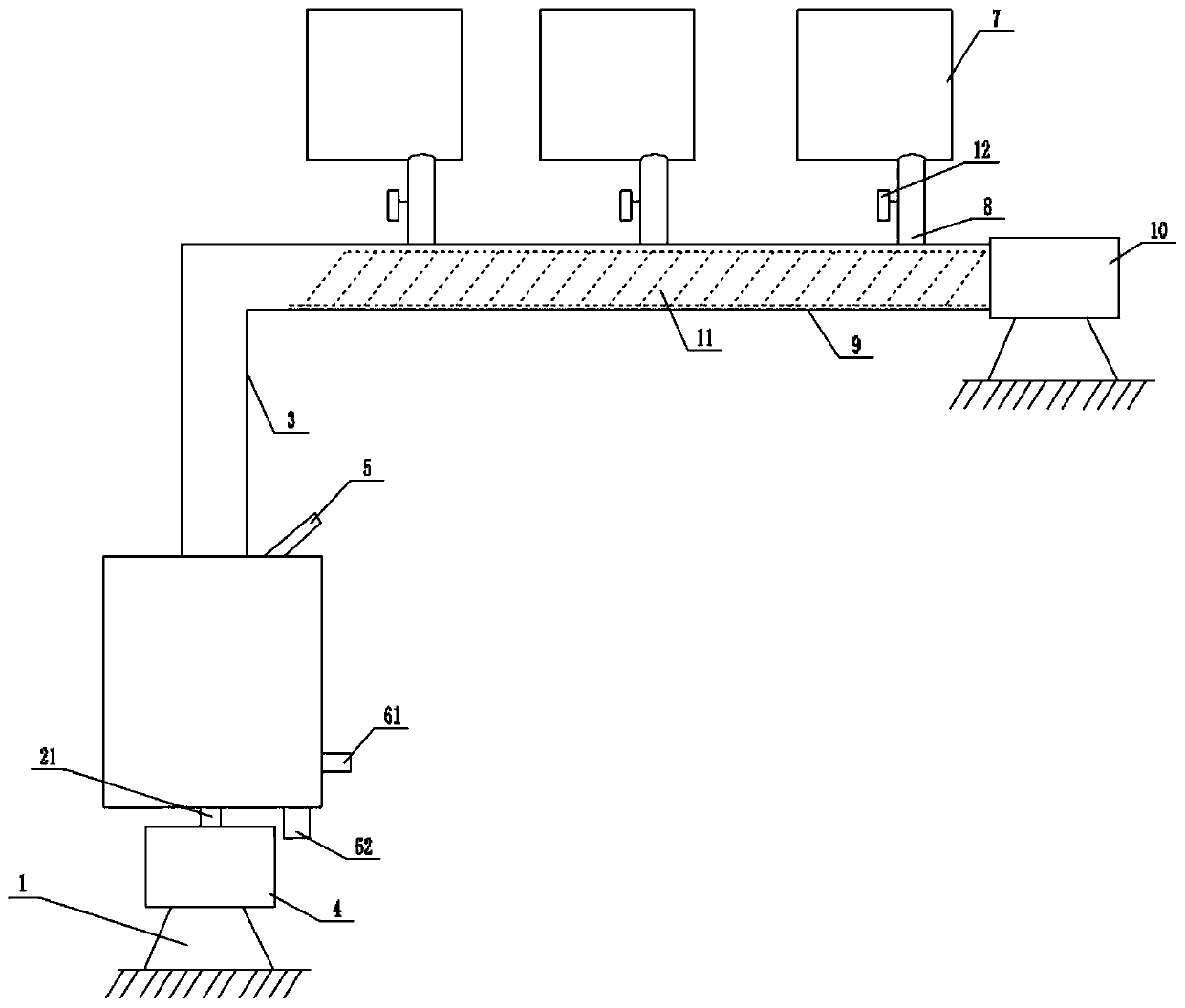

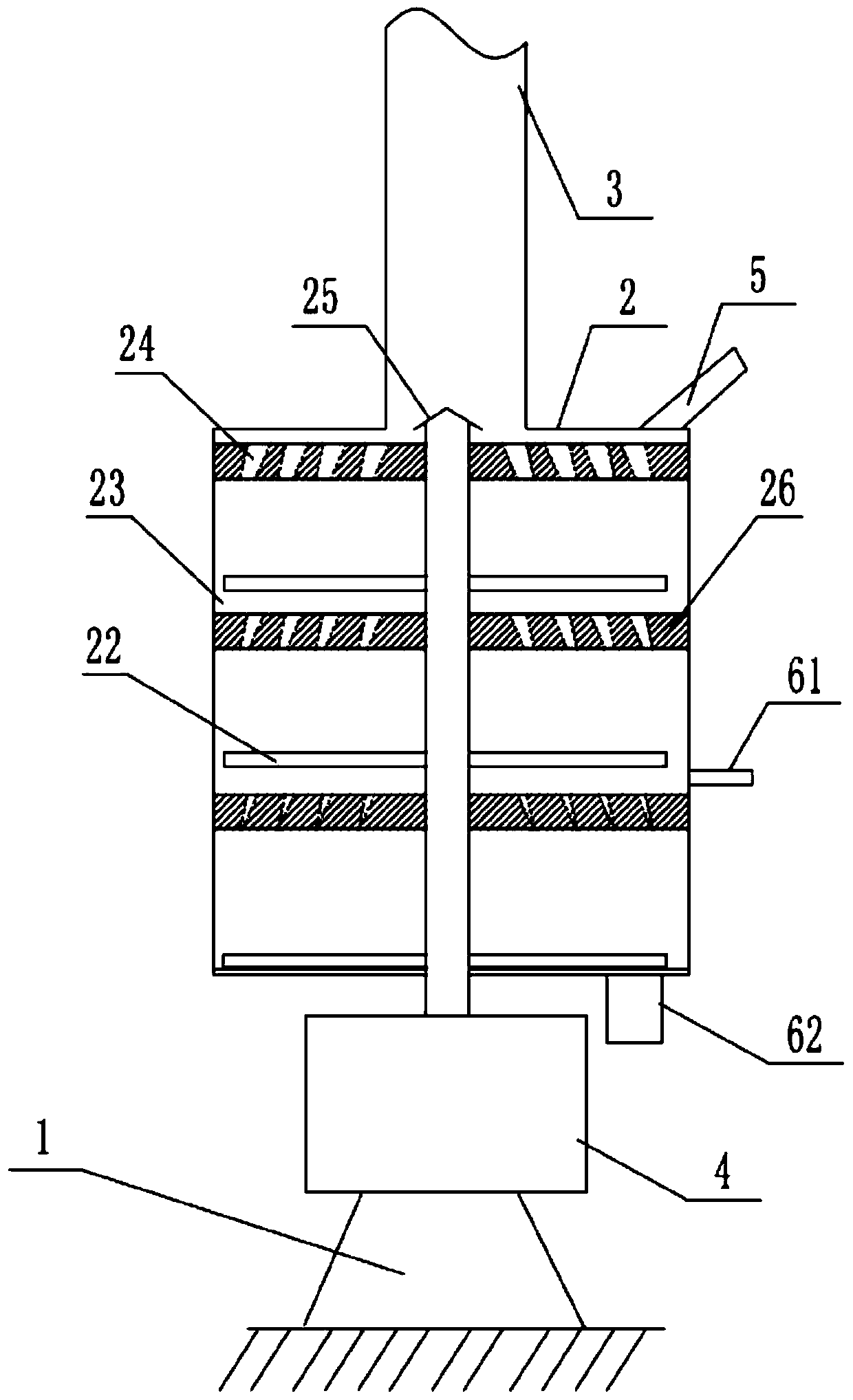

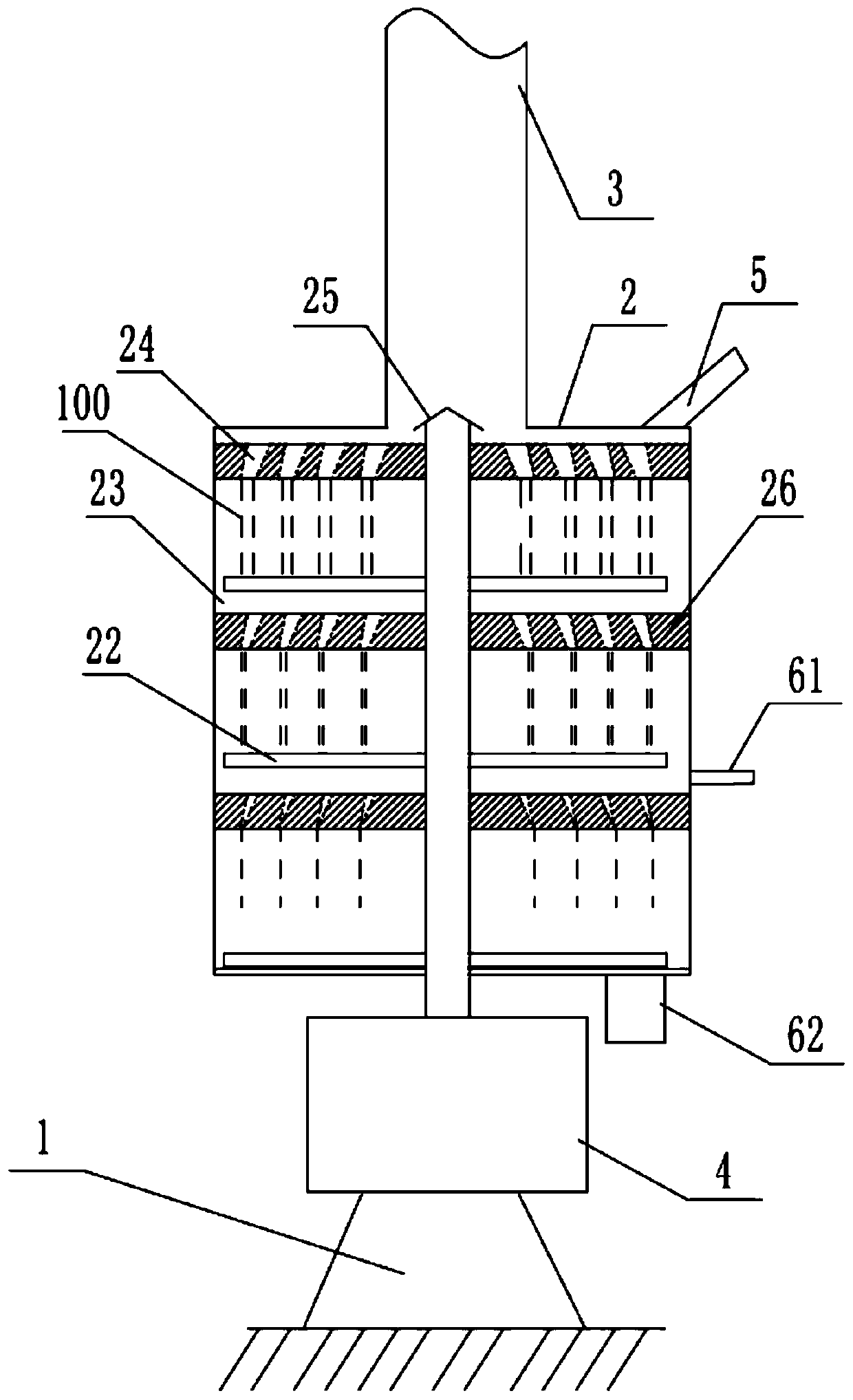

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, a multi-stage mixing device for high-strength composite material raw materials, including the first-stage screw agitating and feeding structure and the second-stage mixing bin agitating structure, the output end of the first-stage screw agitating and feeding structure and the second-stage mixing bin The connection setting of the input port of the stirring structure.

[0033] The first-stage screw mixing and feeding structure includes a plurality of barrels 7 containing resin raw materials. The bottom of the barrels 7 is provided with an outlet pipe 8. The outlet pipes 8 communicate with the inside of the barrel 7. The outlet pipes 8 are vertically arranged, and the bottom of the outlet pipes 8 is arranged. There is a main pipe 9, the main pipe 9 is arranged horizontally, and the upper side of the main pipe 9 is provided with a plurality of interfaces, which are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com