Floatation apparatus and floatation method for promoting floating of coarse particle lean intergrowth

A flotation device and coarse particle technology, which is applied in flotation, solid separation, etc., can solve the problem of not fundamentally improving the flotation capacity of the coarse particle-poor conjoined cells, and the time it takes for the coarse particle-poor conjoined cells to float and foam to rise. It can achieve the effect of good promotion and application value, high mineral utilization rate and lower mineral processing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

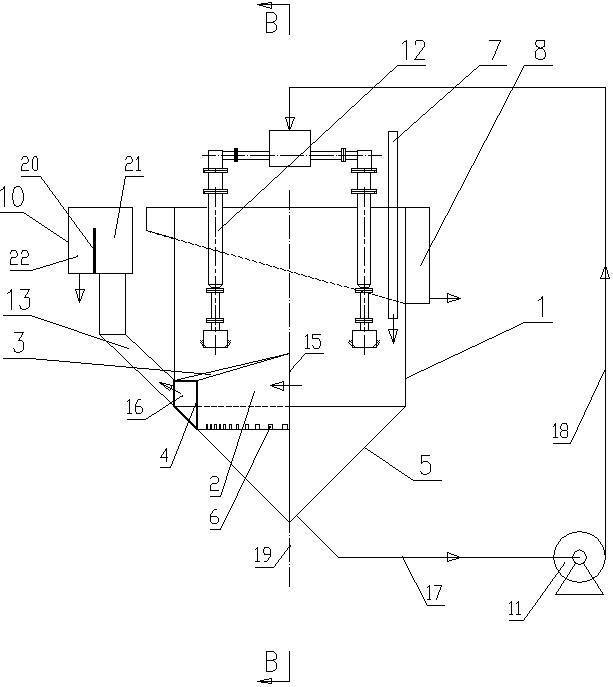

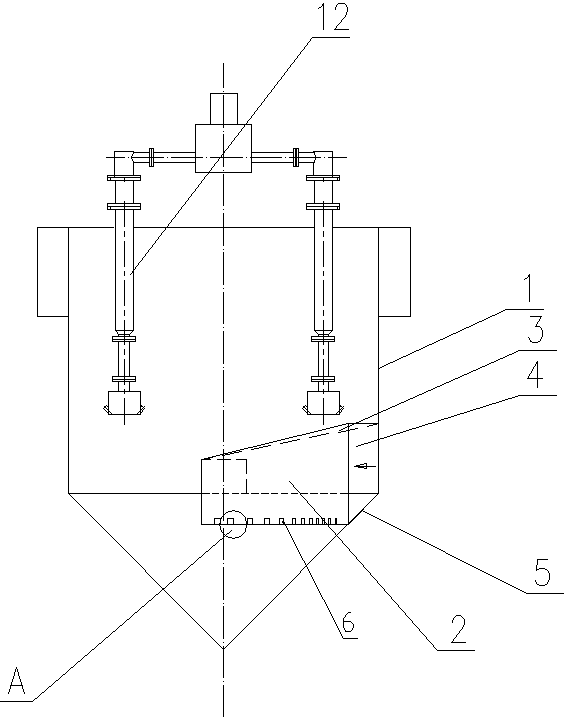

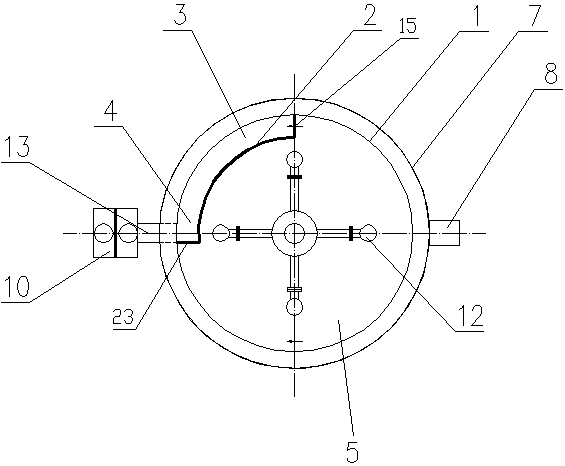

[0043] Such as Figure 1 to Figure 4 As shown, the flotation device for promoting the flotation of coarse-grained and poor intergrowths of the present invention includes a cylindrical tank body 1, a mineralization system 12 is arranged in the tank body 1, and a foam for mineralized foam flowing out is connected to the top of the tank body 1 The chute 8 and the tank body 1 are downwardly connected with a conical bottom 5 with a large top and a small bottom and a hollow setting, and the feed pipe 7 of the flotation pulp extends into the tank body; the tank body 1 can also be square.

[0044] The cavity formed by the communication between the tank body 1 and the conical bottom 5 is provided with a coarse-grained sedimentation tank 4, and the bottom of the coarse-grained sedimentation tank 4 is provided with a row of coarse-grained discharge holes 6 for coarse grains to flow out, and each coarse-grained discharge hole Gravity valves 14 are provided at 6 places;

[0045] One end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com