Efficient seed separator

A technology of cleaning machine and seeds, applied in the direction of solid separation, sieve, grid, etc., can solve the problems of difficult seed impurity removal, small screening area, easy to wear, etc., to improve the screening efficiency, increase the screening area, improve the The effect of cleaning quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

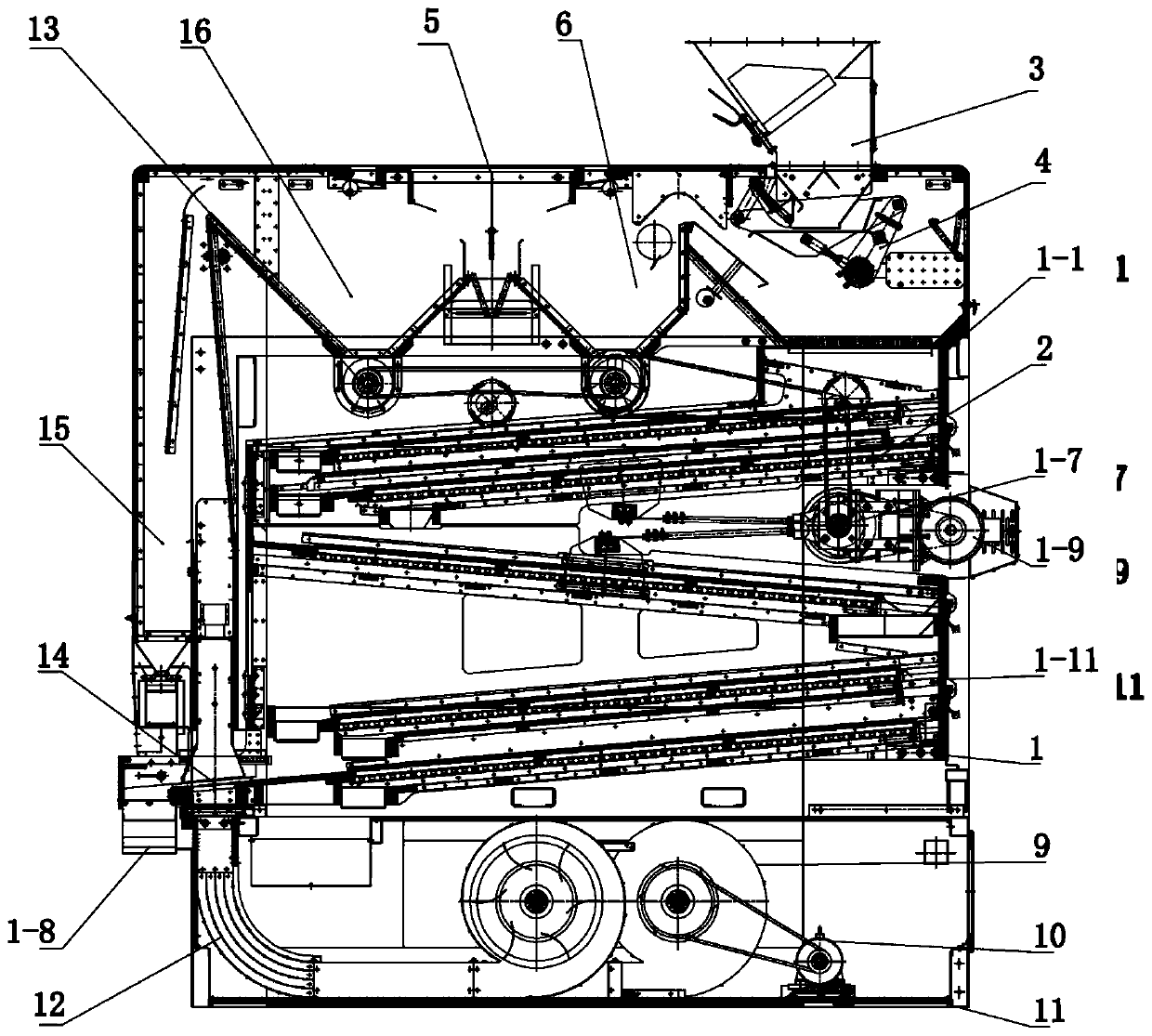

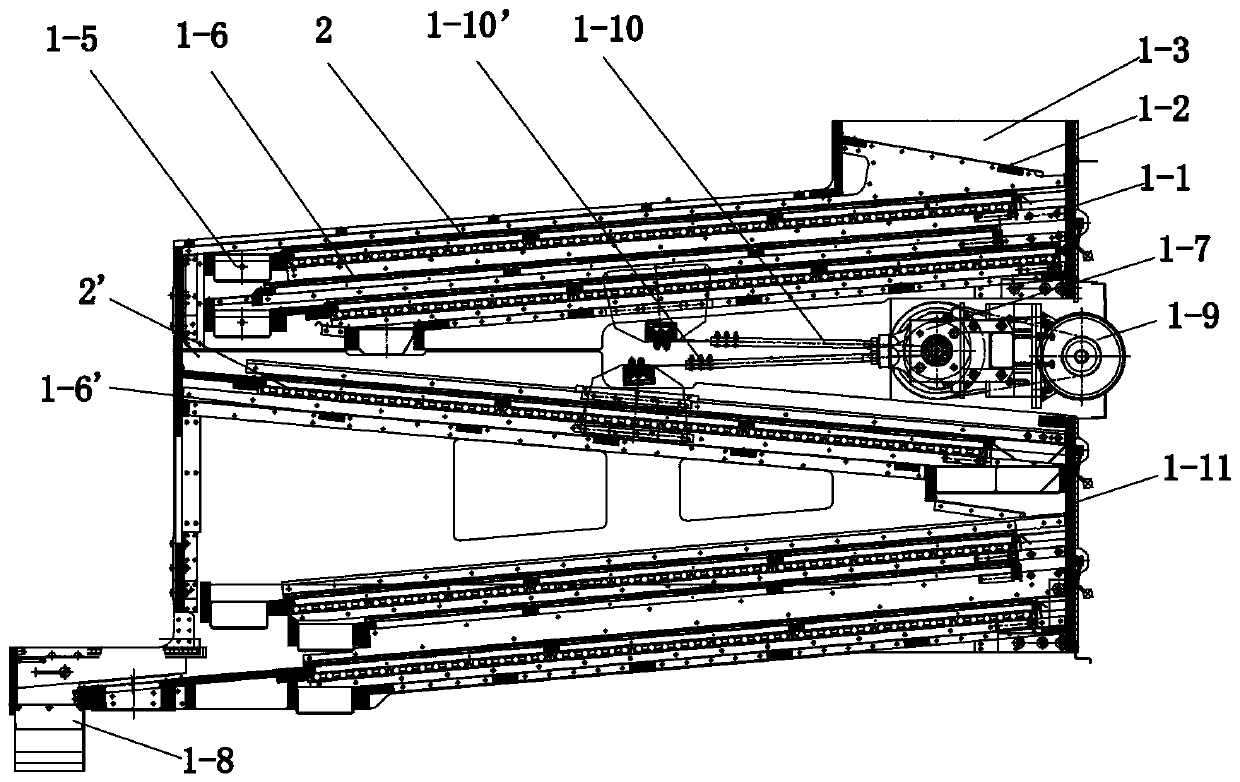

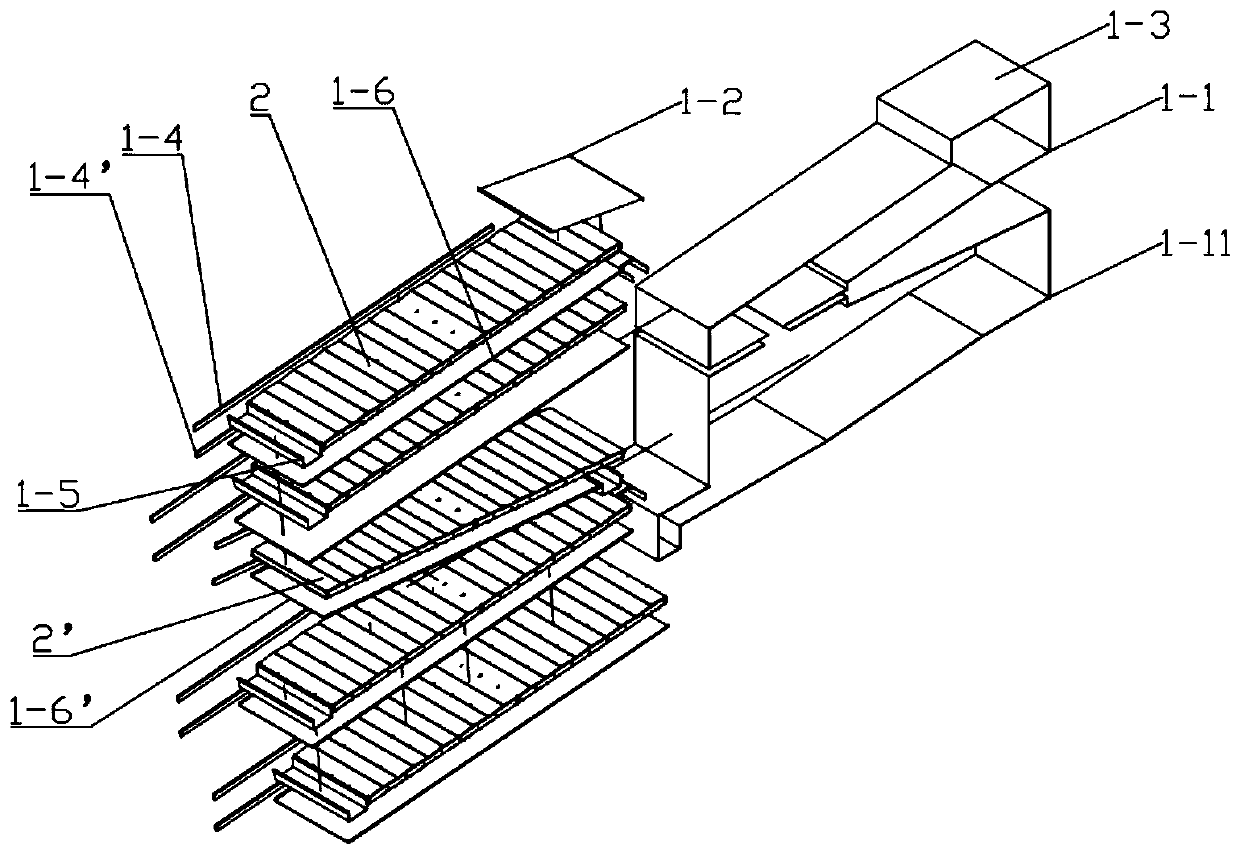

[0035] The high-efficiency seed cleaning machine of the present embodiment is as figure 1 Shown, the top front end of frame 11 is the feeding hopper 3 that contains vibrating feeding device 4 (structure is similar to prior art), and the center of frame 11 top is the suction port 5 of external exhaust fan, and the suction port 5 Front and rear bucket-shaped settling chambers 6, 16 with screw conveyors 13 at the bottom are respectively installed on both sides below. From the bottom of the feed hopper 3 (the distance between it and the feed inlet) to the air outlet 5, a winnowing air path is formed, and the lighter impurities in the seeds to be cleaned can be directly sucked into the settling chamber first. The end of the rear bucket-shaped settling chamber 16 away from the feed hopper 3 communicates with the upper end of the vertical rear air suction channel 15 . The below of feed hopper 3 and the screening part 1 that is arranged in frame 11 middle parts (see figure 2 , im...

Embodiment 2

[0051] The basic structure of the high-efficiency seed cleaning machine of this embodiment is exactly the same as that of the embodiment, the difference being that the vibrating mechanism includes an eccentric wheel mechanism driven by a motor between the upper screen box and the lower screen box and the two phases are staggered by 180°, and the two eccentric wheels The mechanism is respectively hinged with the upper screen box and the lower screen box through connecting rods. The upper screen box and the lower screen box respectively form a moving pair with the upper track and the lower track fixed on the frame at an angle of 1 / 2 of the gravity of the seeds to be cleaned. Constitute the eccentric wheel link slider mechanism. In this way, when working, the uppermost and second upper high-efficiency seed cleaning sieves in the upper sieve box and the second lower and lowermost high-efficiency seed cleaning sieves in the lower sieve box respectively move back and forth in a strai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com