Single angle grinding equipment for door and window weld bead

A kind of equipment and welding bead technology, which is applied in the field of single-angle grinding equipment, can solve the problems of poor processing quality, damage to the base material of doors and windows, and low efficiency, and achieve the effect of stable grinding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

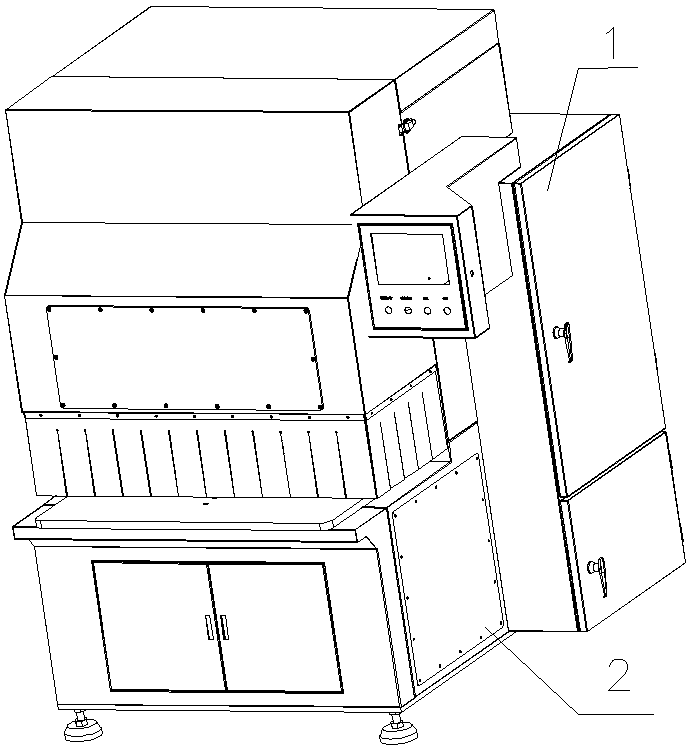

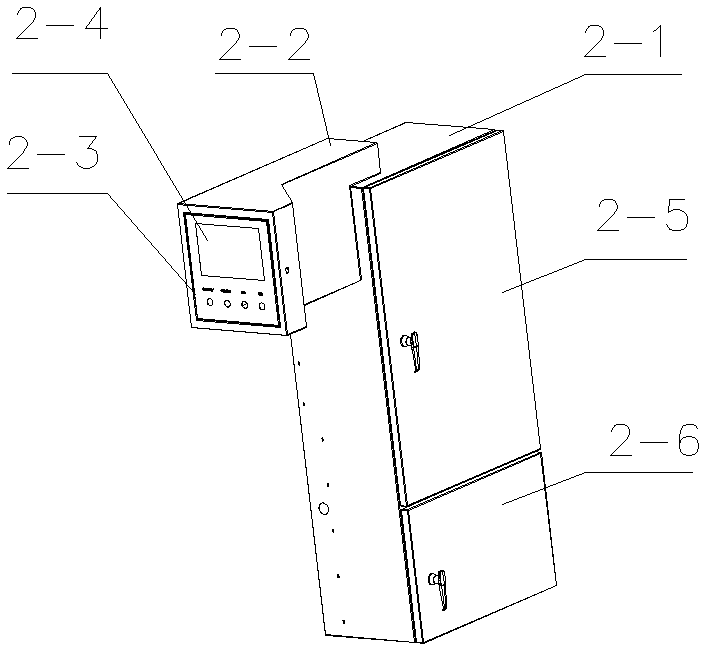

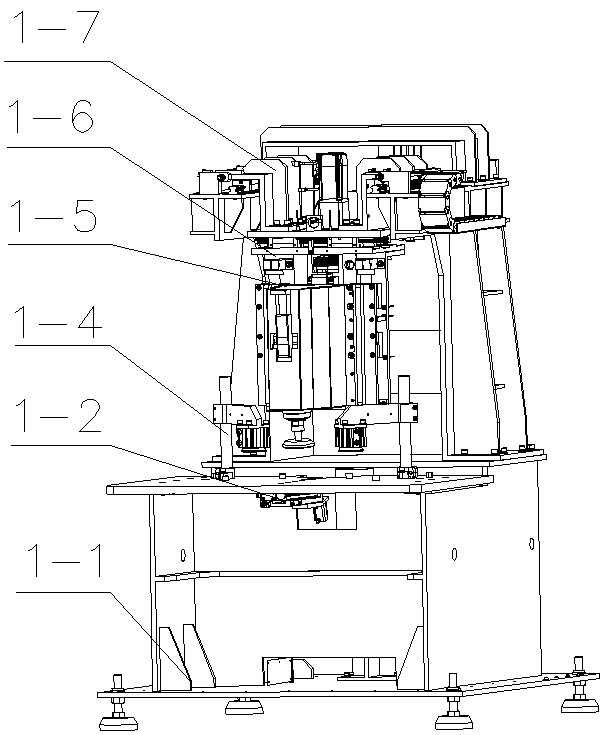

[0035] A kind of equipment that single-angle grinding is carried out to door and window weld bead, and its composition comprises: mechanical system 1, control system 2, described mechanical system comprises frame group 1-1, and described frame group fixed unloading mechanism 1- 2 and the loading mechanism 1-3, the described unloading mechanism is connected to the pressing mechanism 1-4, the described pressing mechanism is connected to the grinding mechanism 1-5, and the described grinding mechanism is connected to the Z-axis operating mechanism 1-6 and Y-axis operating mechanism 1-7, the control system includes a control cabinet 2-1, the control cabinet is connected to a screen box 2-2, and the screen box is connected to a control panel 2-3, and the control panel has The screen 2-4, the screen box is connected with the electric control box door 2-5 and the air control box door 2-6.

Embodiment 2

[0037] The equipment for single-corner grinding of the door and window weld bead described in embodiment 1, the frame set includes a base plate 1-1-1, the base plate is connected to the frame body 1-1-2, the The bottom of the base plate is connected to the ground feet 1-1-3, the second half of the frame is connected to the column 1-1-4, the front half of the frame is connected to the workbench 1-1-5, and the The column is connected to the slide rail 1-1-6, the slide rail is connected to the beam 1-1-7, the slide rail is connected to the sensor 1-1-8, and the end of the slide rail is connected to the scanning block 1- 1-9, the slide rail is used with the pressing head 1-1-10, the pressing head is fixed on the slide rail, and the beam is connected to the rack 1-1-11.

Embodiment 3

[0039] The equipment for single-angle grinding of the door and window weld bead described in embodiment 1, the described sheet unloading mechanism includes a bracket 1-2-1, and the described bracket is connected to the cylinder A, 1-2-2, and the described Cylinder connects presser foot 1-2-3, and described support connects cylinder B, 1-2-4. The unloading mechanism starts, the cylinder drives the bracket, the cylinder and the presser foot to extend forward, the inner slope of the bracket is inserted between the suction cup and the grinding disc during the movement, and then the cylinder drives the presser foot to press the grinding disc, and then the cylinder starts to recover and tear off the grinding disc Finally, the cylinder drives the presser foot to recover, and the removed grinding disc falls.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com