Self-propelled single-track mountainous area conveyor

A technology of single track and transport machine, which is applied in the direction of monorail system, transportation and packaging, and the operating mechanism of railway vehicle brakes. It can solve the problems of inability to adapt to mountainous terrain, inability to transport horizontally, and restrictions on operation and communication, and achieve light weight and labor reduction. Intensive, space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

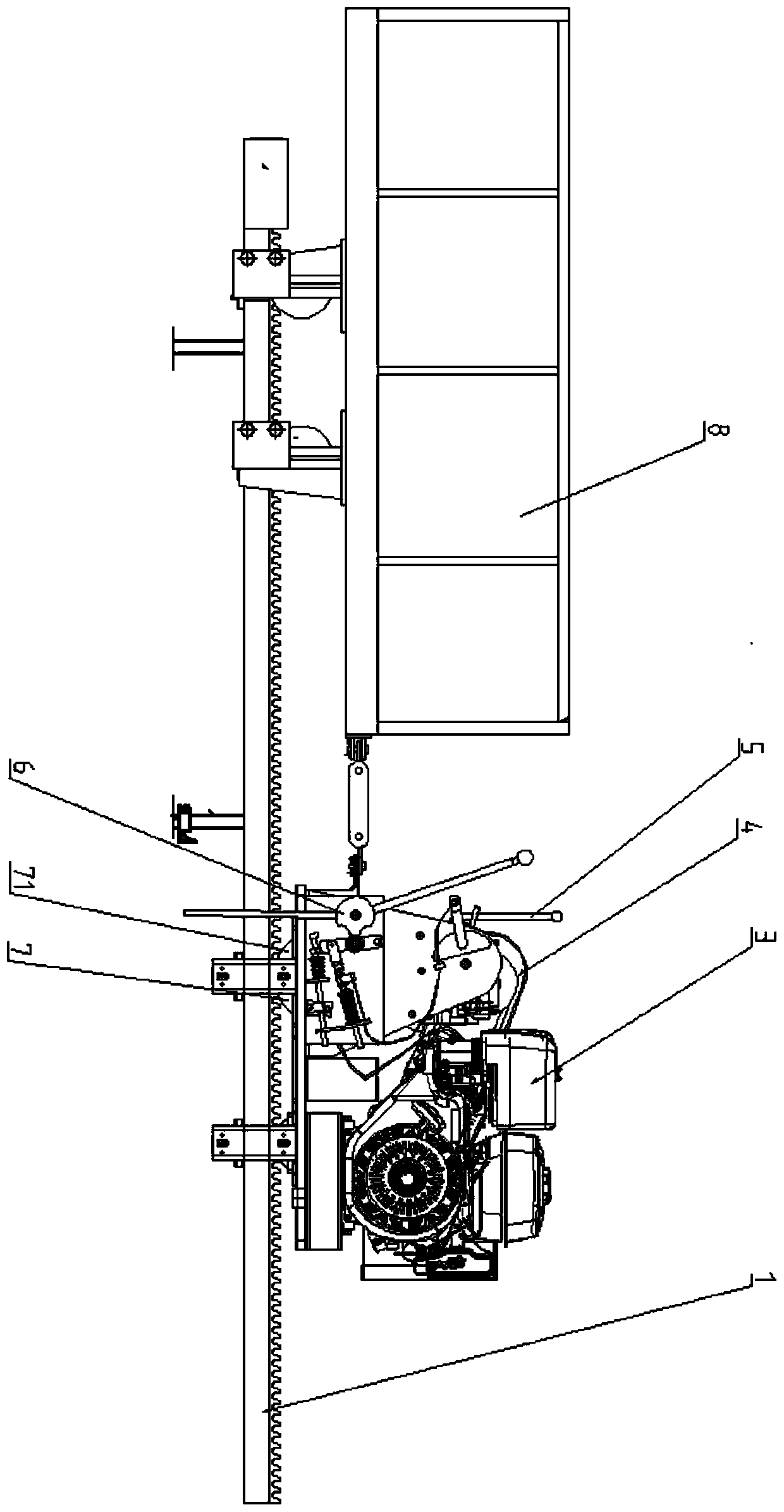

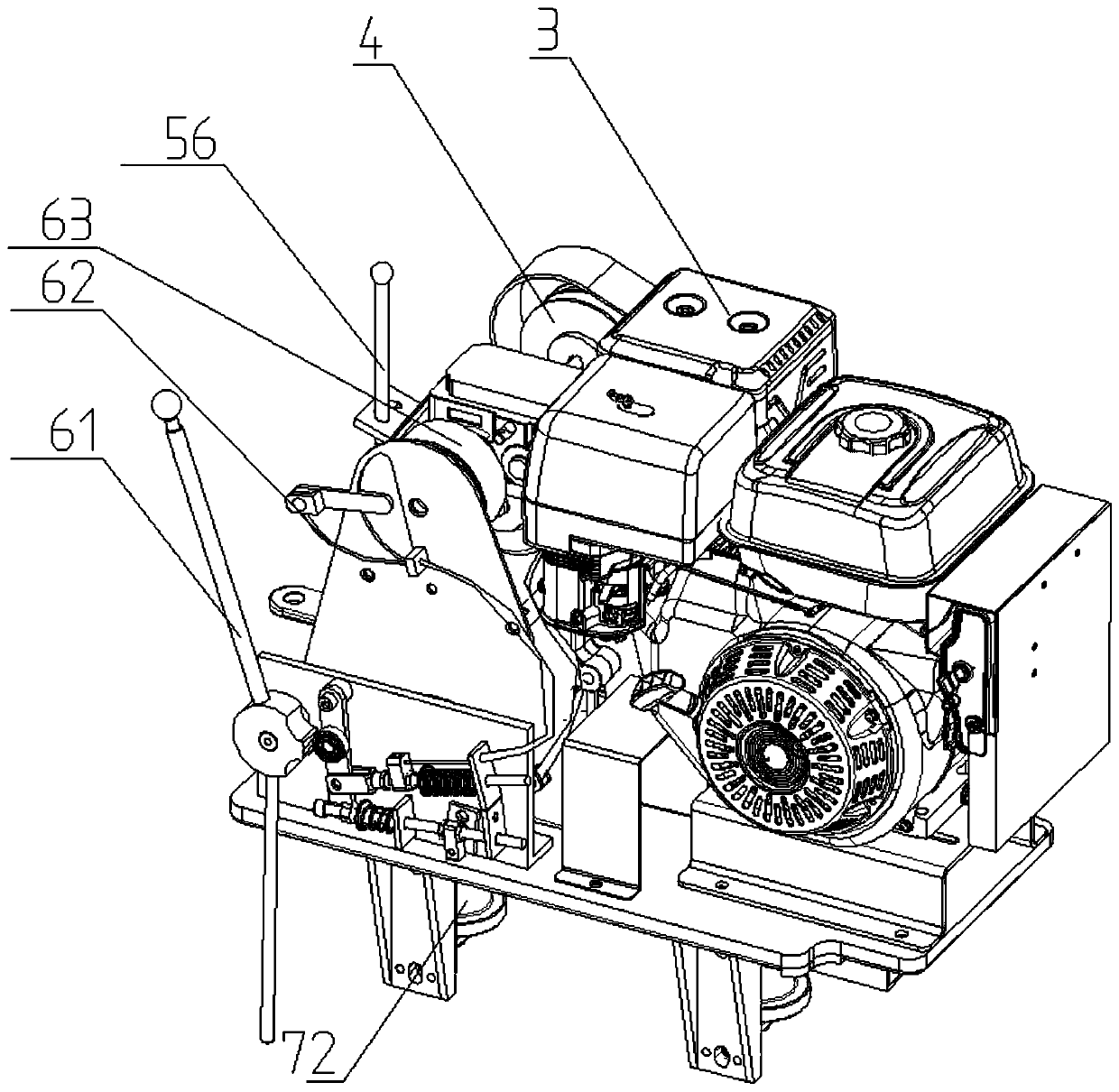

[0025] As an embodiment, the traveling device 7 includes a driving wheel 71, a driven wheel and a clamping wheel set, and the driving wheel 71 and the driven wheel are all arranged under the frame 2 and connected to the teeth on the upper surface of the toothed monorail 1. The clamping wheel set includes clamping wheels 72 symmetrically arranged on both sides of the driving wheel 71 and the driven wheel, and the clamping wheels 72 are in contact with the side of the toothed single track 1 and can move Rolling, the clamping wheel set is used to prevent the driving wheel 71 and the driven wheel from detaching from the toothed single track 1 .

[0026] As an implementation manner, the driven wheel is a universal wheel.

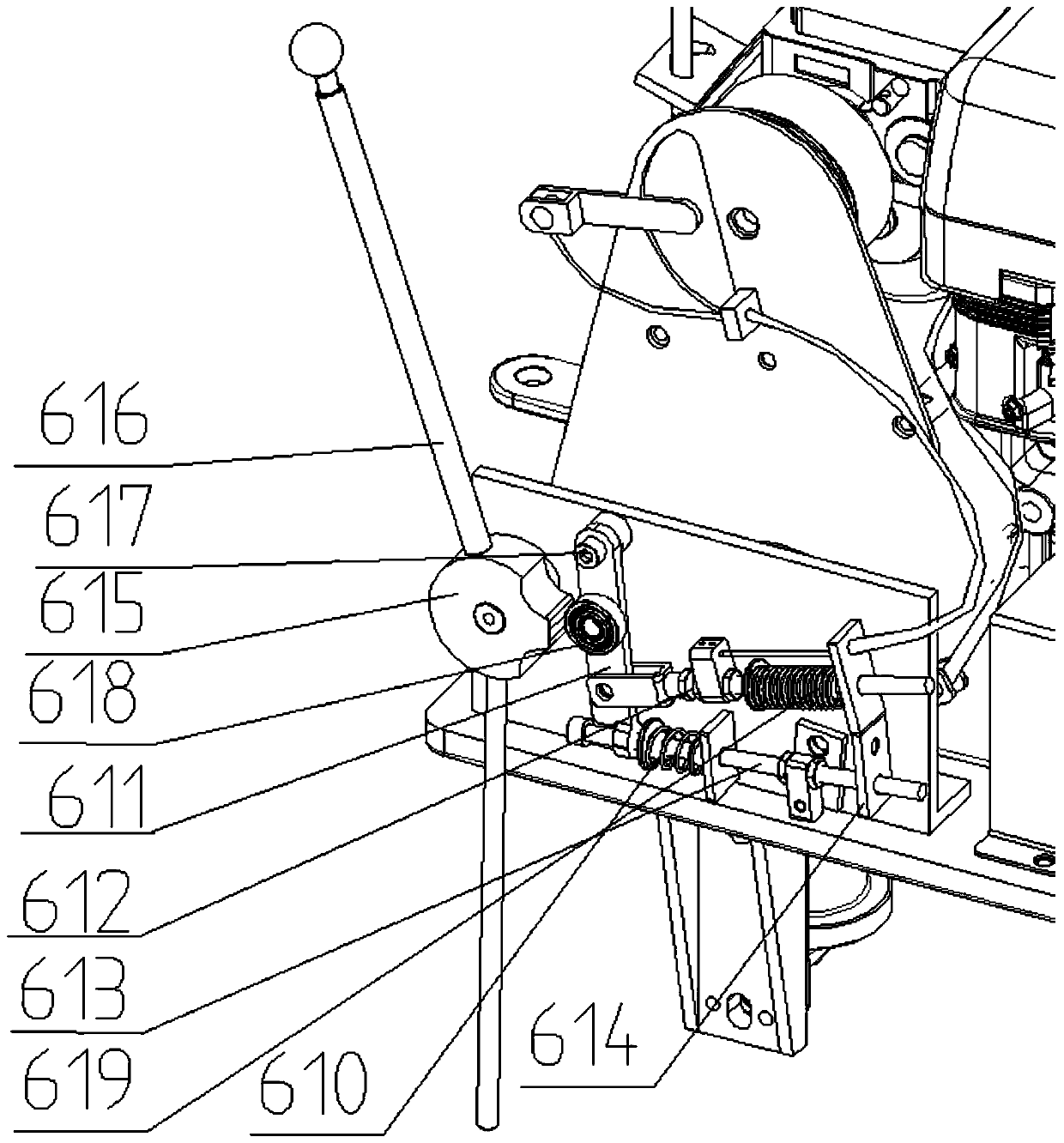

[0027] As an embodiment, the brake mechanism 6 includes a tension mechanism 61, a connecting wire 62, a brake disc 63, a brake wire and a brake mechanism, and the tension mechanism 61 is used to drive the brake disc 63 by tightening the connection wire 62. Rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com