Nickel-based high-temperature alloy and preparing method thereof

A nickel-based superalloy and superalloy technology, applied in the field of additive manufacturing, can solve the problem that the alloy performance is difficult to meet higher temperature and new demand requirements, and achieve the effect of high strength, low density and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

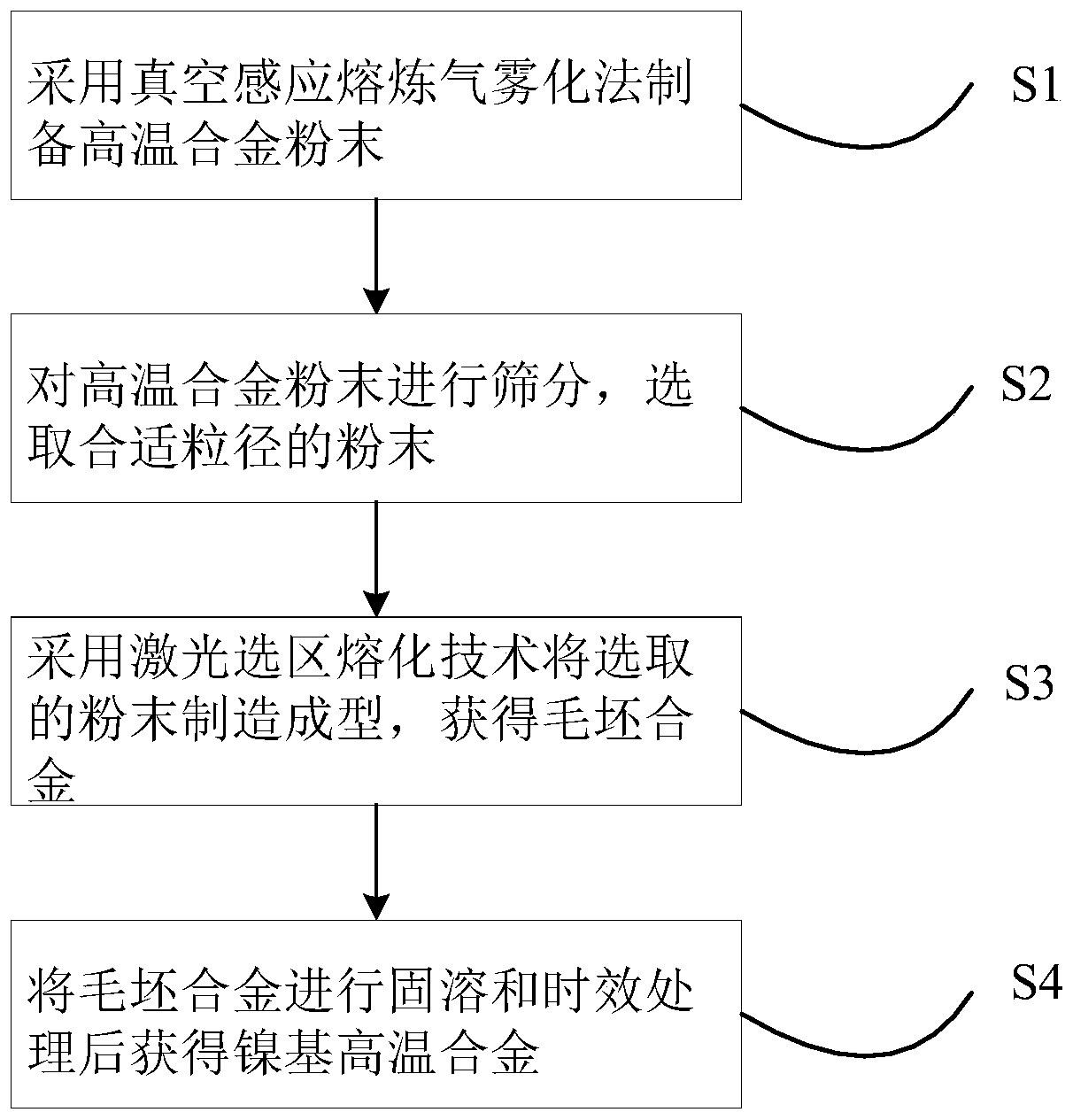

[0050]Firstly, superalloy powder was prepared by vacuum induction melting gas atomization method. The composition of alloy powder is shown in Table 1.

[0051] Then sieve the superalloy powder, and select the powder with a particle size of 15 μm-45 μm.

[0052] The selected powder is manufactured and shaped by laser selective melting technology to obtain the blank alloy.

[0053] The nickel-based superalloy is obtained after solid solution and aging treatment of the blank alloy.

[0054] The temperature of solution treatment is 1100°C, and the time is 2h; the temperature of aging treatment is 900°C, and the time is 3h.

[0055] The density and tensile strength at 900°C of the prepared nickel-based superalloy were tested, and the results are shown in Table 2.

Embodiment 2

[0057] Firstly, superalloy powder was prepared by vacuum induction melting gas atomization method. The composition of alloy powder is shown in Table 1.

[0058] Then sieve the superalloy powder, and select the powder with a particle size of 20 μm-35 μm.

[0059] The selected powder is manufactured and shaped by laser selective melting technology to obtain the blank alloy.

[0060] The nickel-based superalloy is obtained after solid solution and aging treatment of the blank alloy.

[0061] The temperature of solution treatment is 1175°C, and the time is 1h; the temperature of aging treatment is 900°C, and the time is 3h.

[0062] The density and tensile strength at 900°C of the prepared nickel-based superalloy were tested, and the results are shown in Table 2.

Embodiment 3

[0064] Firstly, superalloy powder was prepared by vacuum induction melting gas atomization method. The composition of alloy powder is shown in Table 1.

[0065] Then sieve the superalloy powder, and select the powder with a particle size of 30 μm-45 μm.

[0066] The selected powder is manufactured and shaped by laser selective melting technology to obtain the blank alloy.

[0067] The nickel-based superalloy is obtained after solid solution and aging treatment of the blank alloy.

[0068] The temperature of solution treatment is 1200°C, and the time is 1.5h; the temperature of aging treatment is 900°C, and the time is 3h.

[0069] The density and tensile strength at 900°C of the prepared nickel-based superalloy were tested, and the results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com