Rubbing-first-bandhnu-then production method of silk plants

A technology for silk fabrics and plants, applied in dyeing, textiles and papermaking, etc., can solve problems such as small side effects, achieve good economic benefits, improve aesthetics, and improve color fastness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0027] (1) The selection of raw materials is: silk fabric, acetic acid, soda ash, alum, ferric chloride, copper sulfate, iron acetate, water repellent, madder, sumac, frozen green, pomegranate peel, various plant leaves, roots, flowers , stem, fruit.

[0028] (2) The technological process is as follows: it includes the following steps: collect leaves, roots, flowers, stems, and fruits of plants according to patterns and colors → soak in water repellent and mordant mixture → soak silk fabrics in acetic acid solution and squeeze dry → use transparent glue on the plants Fit on the front of the fabric according to the graphic requirements → roll into a reel and tie it tightly with a thread → steam and color → remove leaves → bake → tie pattern → plant dyeing → washing → drying.

[0029] Wherein, the specific production process operation is as follows:

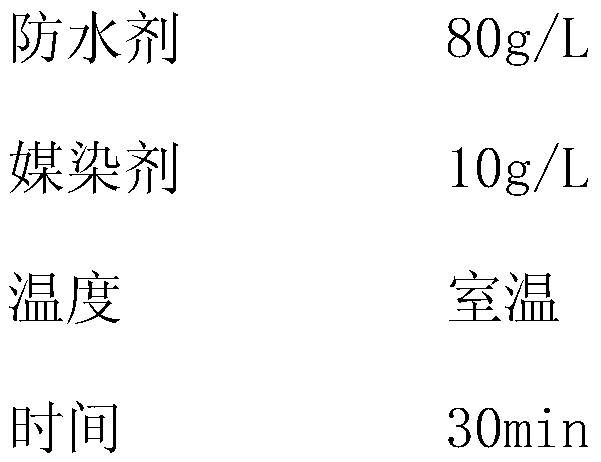

[0030] Treatment of leaves, roots, flowers, and stems before rubbing: immerse plants in the water repellent and mordant mixture ...

specific Embodiment 2

[0040] (1) The selection of raw materials is: silk fabric, acetic acid, soda ash, alum, ferric chloride, copper sulfate, iron acetate, water repellent, madder, sumac, frozen green, pomegranate peel, various plant leaves, roots, flowers , stem, fruit.

[0041](2) The technological process is as follows: it includes the following steps: collect leaves, roots, flowers, stems, and fruits of plants according to patterns and colors → soak in water repellent and mordant mixture → soak silk fabrics in acetic acid solution and squeeze dry → use transparent glue on the plants Fit on the front of the fabric according to the graphic requirements → roll into a reel and tie it tightly with a thread → steam and color → remove leaves → bake → tie pattern → plant dyeing → washing → drying.

[0042] Wherein, the specific production process operation is as follows:

[0043] Treatment of leaves, roots, flowers, and stems before rubbing: immerse plants in the water repellent and mordant mixture b...

specific Embodiment 3

[0053] (1) The selection of raw materials is: silk fabric, acetic acid, soda ash, alum, ferric chloride, copper sulfate, iron acetate, water repellent, madder, sumac, frozen green, pomegranate peel, various plant leaves, roots, flowers , stem, fruit.

[0054] (2) The technological process is as follows: it includes the following steps: collect leaves, roots, flowers, stems, and fruits of plants according to patterns and colors → soak in water repellent and mordant mixture → soak silk fabrics in acetic acid solution and squeeze dry → use transparent glue on the plants Fit on the front of the fabric according to the graphic requirements → roll into a reel and tie it tightly with a thread → steam and color → remove leaves → bake → tie pattern → plant dyeing → washing → drying.

[0055] Wherein, the specific production process operation is as follows:

[0056] Treatment of leaves, roots, flowers, and stems before rubbing: immerse plants in the water repellent and mordant mixture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com