Through-type evacuated collector tube machining process and inner tube forming device thereof

A vacuum heat collecting tube and processing technology, which is applied in glass forming, glass reshaping, solar collectors, etc., can solve problems affecting the number of heat absorbing tubes installed, affecting heat preservation effect, air introduction, etc., to reduce damage The effect of improving the rate, improving the molding efficiency, and increasing the ventilation volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings.

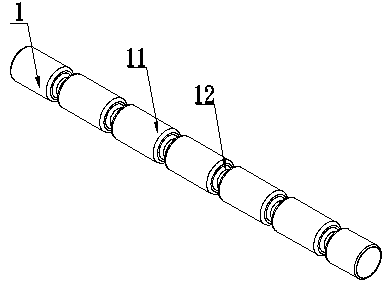

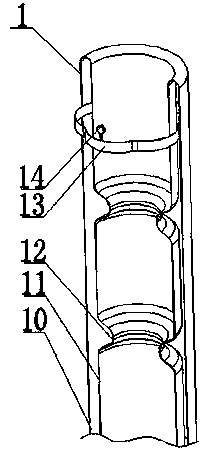

[0043] As shown in the accompanying drawings, the whole body of the through-type vacuum heat collecting tube targeted by the present invention adopts an inner tube 11 and an outer tube 10 made of high borosilicate glass to form at the end, and the outer diameter of the inner tube 11 is provided with a plurality of variable diameters. Zone 12; a snap ring 13 is fixed between the outer diameter of the inner tube 11 and the inner wall of the outer tube 10, and the snap ring 13 is fixed with a getter module 14;

[0044] The production steps of the above-mentioned through-type vacuum heat collecting tube are as follows:

[0045] ⑴Inner tube processing:

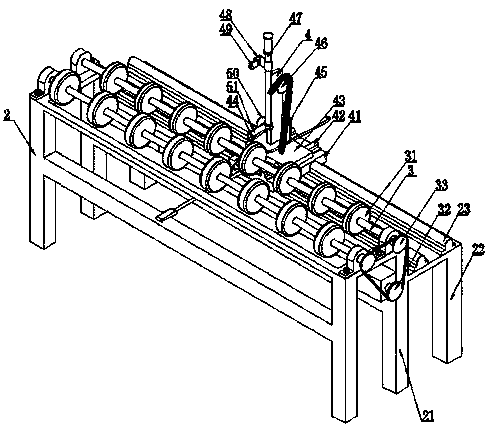

[0046] ①The inner tube is made of circular high borosilicate glass material; image 3 with Figure 4 as well as Figure 5As shown, the inner tube blank is locally heated in the variable diameter area 12 while rotating, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com