Improved unified particle swarm algorithm-based mechanical part machining pipeline scheduling method

A particle swarm algorithm, a technology of mechanical parts, applied in general control systems, control/regulation systems, instruments, etc., can solve problems such as combinatorial optimization that cannot be directly applied to discrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

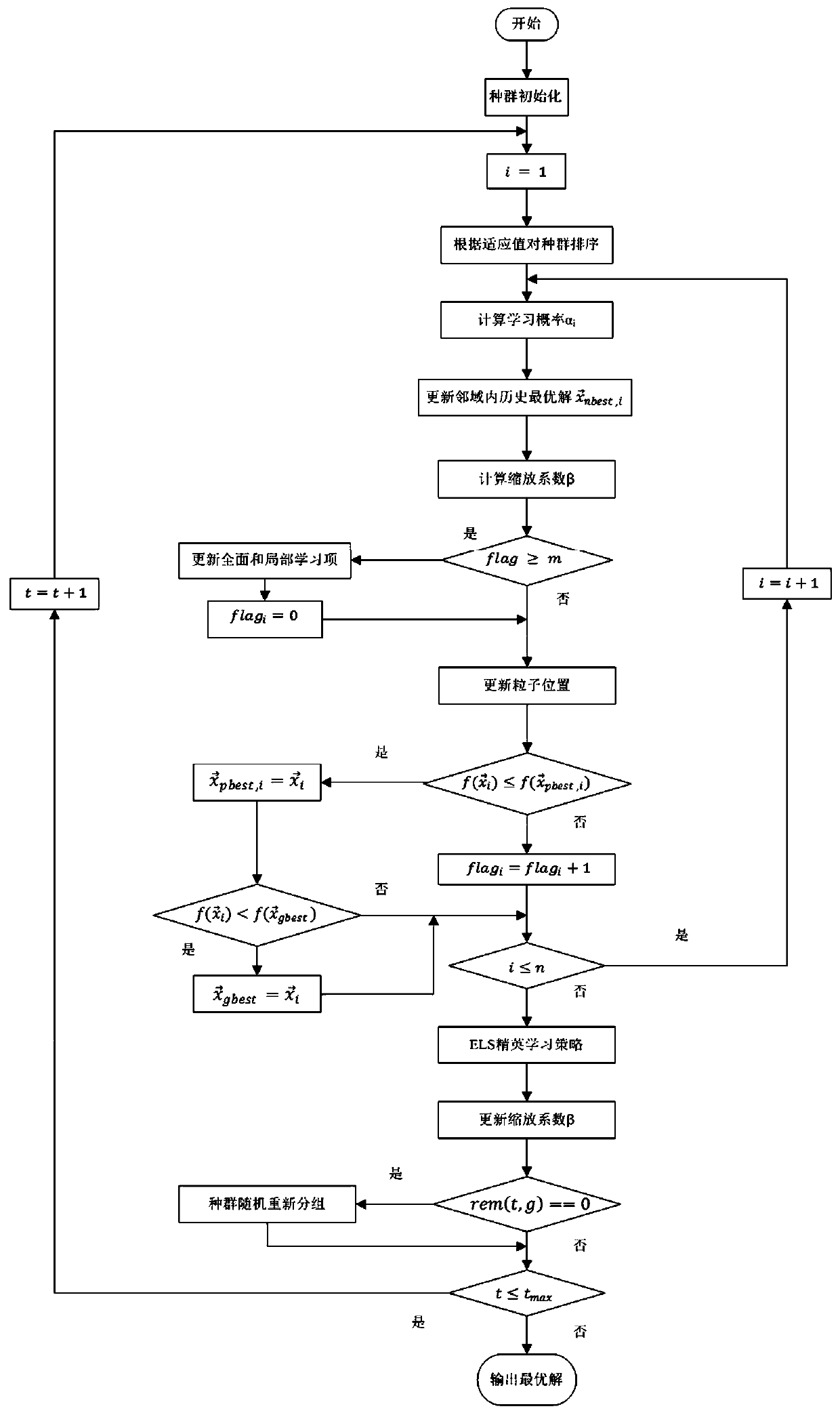

Method used

Image

Examples

Embodiment

[0136] The method of the present invention is used for the dispatching of workpiece processing order below, can be the similar workpieces such as bearing, assume that its processing time is as shown in the table below:

[0137]

[0138]

[0139] The method of discrete unified particle swarm optimization based on dynamic neighborhood and comprehensive learning for this pipeline scheduling problem is as follows:

[0140] 1. Read in the operation time of mechanical parts processing;

[0141] 2. Initialize the population, including setting the maximum number of iterations G max =50, the population size of the particle swarm N=20, the population reorganization threshold g=5, the learning item reorganization threshold m=3, the range of particles constituting the global learning item p=0.2; use the NEH method to initialize the position x of each particle i ;Set the initial individual historical optimal solution as the initial position; clear the stagnation count flag of partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com