Metal strip material, slitting method, and measuring method for strip material meandering

A measurement method and technology of metal materials, applied in metal processing equipment, mechanical counters/curvature measurement, shearing devices, etc., can solve problems such as product yield reduction, and achieve the effect of suppressing abnormalities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0060] Examples of the present invention are shown below, and the examples are provided for better understanding of the present invention and its advantages, and are not intended to limit the invention.

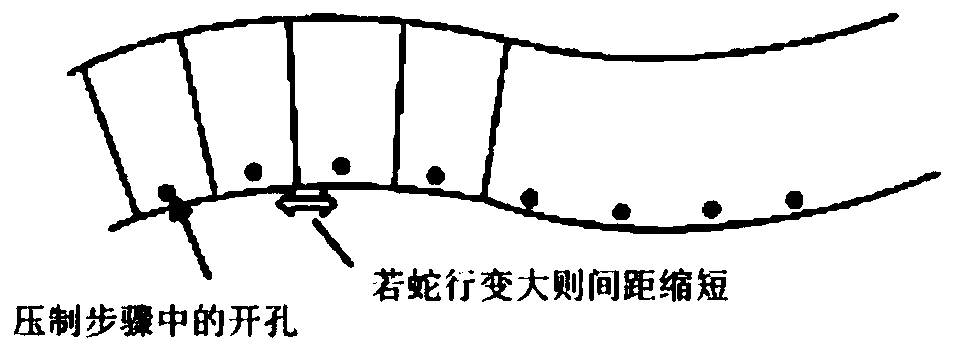

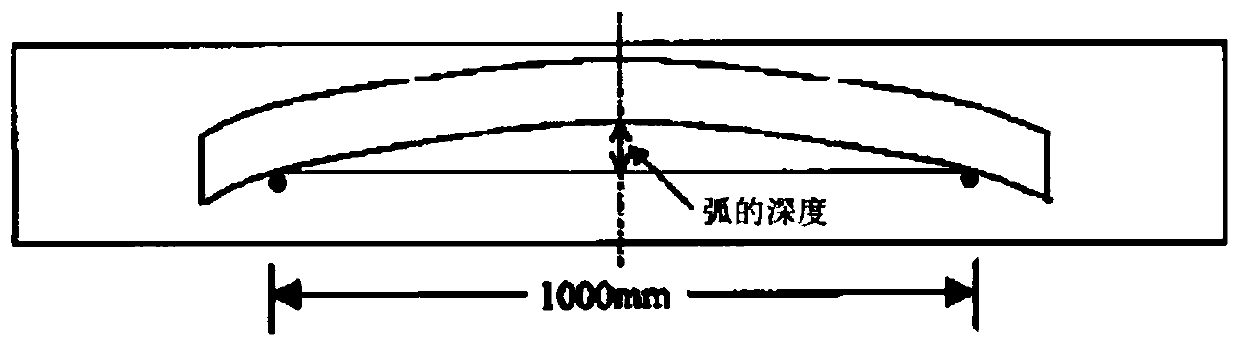

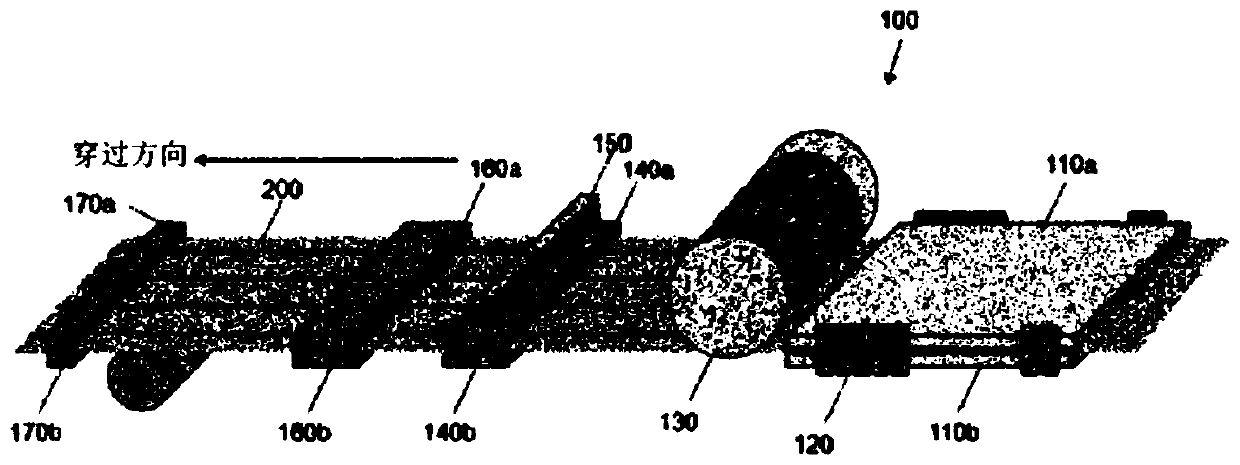

[0061] For the Cason copper alloy (2-4 mass% Ni-0.4-1.0 mass% Si-Cu) having the tensile strength, Vickers hardness, plate thickness and plate width shown in Table 1, using image 3 The slitting machine equipment with the structure shown is used for slitting processing of metal raw materials. Regarding each embodiment and invention example, the length (110a, 110b) of the meandering prevention plate at the front stage of the slitter, the presence or absence of the meandering prevention plate (140a, 140b, 160a, 160b, 170a, 170b) at the rear stage of the slitter, the longitudinal The width of the strip-shaped metal material after cutting is also adjusted as described in Table 1.

[0062] The operating conditions of the slitting machine equipment are as follows.

[0063] Guide r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com