Bud cutting device for humulus lupulus field management

A technology of hops and connecting rods, applied in the direction of harvesters, cutting tools, cutting equipment, etc., can solve the problems of slow speed and hard work, and achieve the effect of easy use and lightening the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

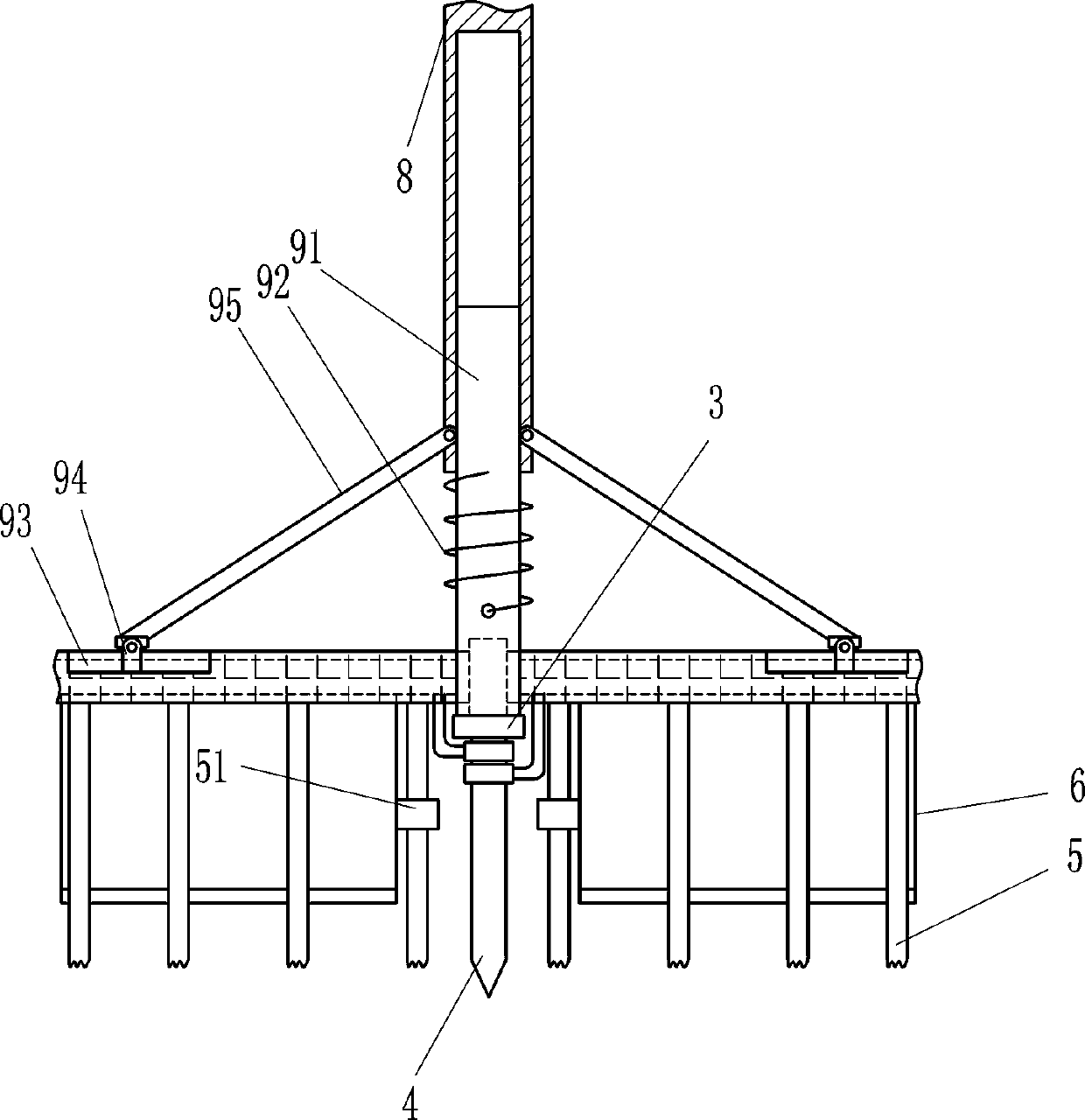

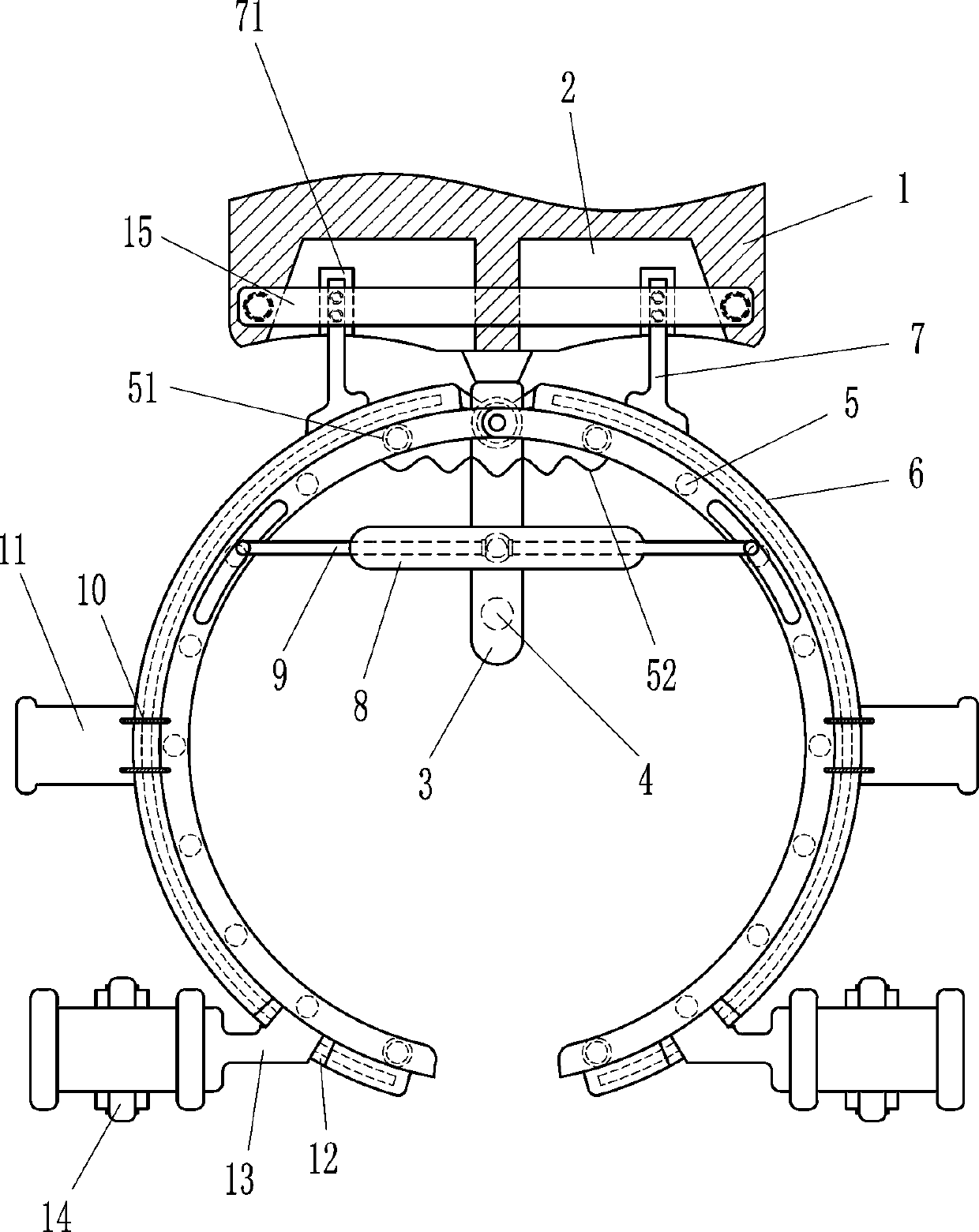

[0017] A bud cutting device for field management of hops, such as Figure 1-2 Shown, comprise the first connecting plate 1, the first connecting rod 3, the inserting rod 4, clear soil bud cutting mechanism, the second connecting rod 7, elevating rod 8, stretching device 9, elastic cord 10 and pedal 11, so The left and right sides of the bottom of the first connecting plate 1 are provided with first transverse grooves 2, the middle of the bottom of the first connecting plate 1 is provided with a first connecting rod 3, and the rear side of the first connecting rod 3 is provided with two A root insertion rod 4, the insertion rod 4 is provided with a soil removal and bud removal mechanism for clearing soil by rotation and cutting buds by vertical movement, and the first connecting rod 3 is provided with a soil removal and bud removal mechanism The stretching device 9 is connected with a lifting rod 8 on the stretching device 9, and at least two elastic ropes 10 are arranged on th...

Embodiment 2

[0024] Such as figure 1 As shown, in order to improve the stability of the equipment work, it also includes a second connecting plate 13 and a sliding wheel 14. The lower part of the front side of the arc blade 6 is provided with a second groove 12, and the arc rake 5 has two left and right sides. A second connecting plate 13 passing through the second groove 12 is fixed to the lower part of the side by bolts, and sliding wheels 14 are fixed to the bottom of the second connecting plates 13 by bolts.

[0025] When the arc-shaped nail rake 5 rotated to the outside, the sliding wheel 14 would be in contact with the ground, so that the arc-shaped nail rake 5 rotating type would be more stable and labor-saving.

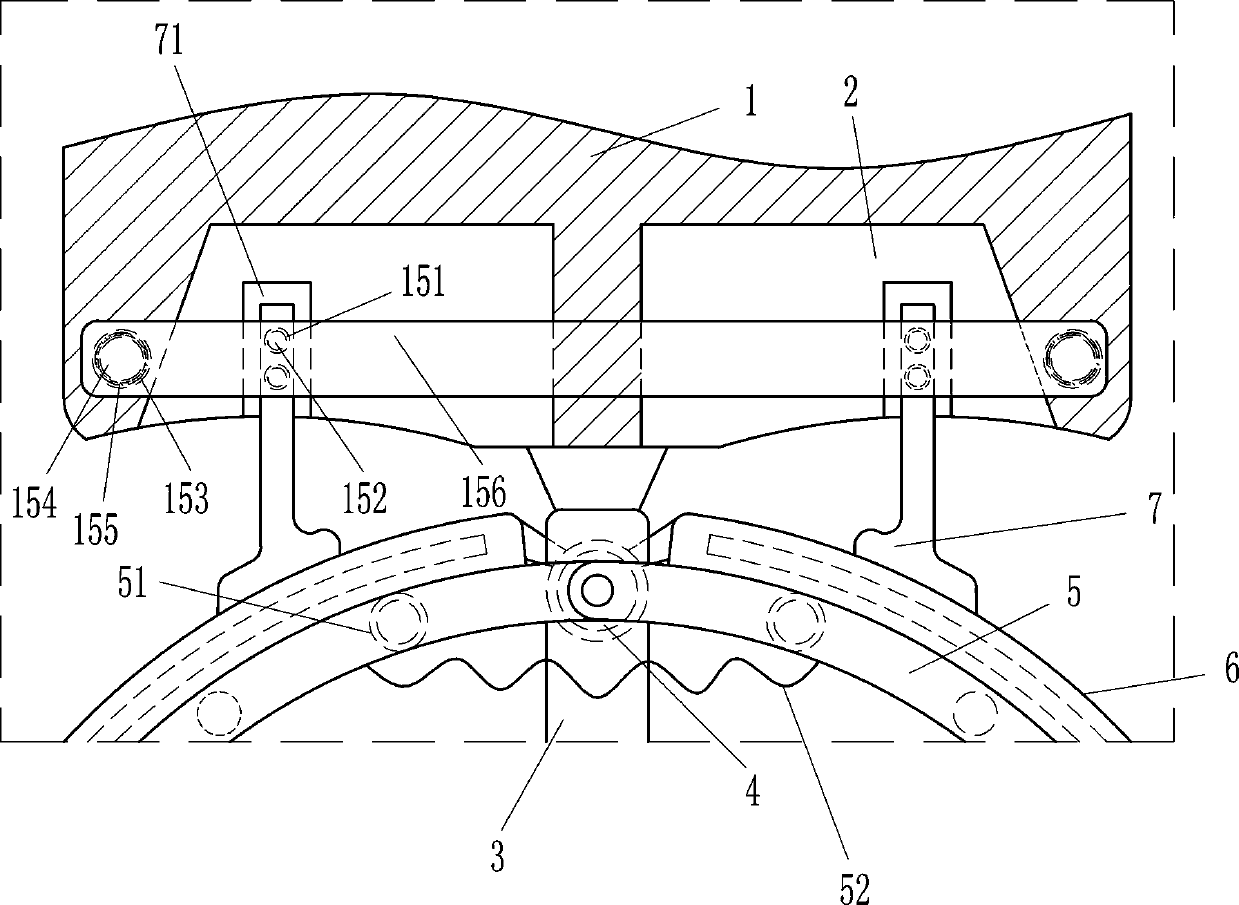

[0026] Such as image 3 As shown, in order to improve the convenience of equipment use, it also includes a pressing device 15. The first connecting plate 1 is provided with a pressing device 15 that moves the arc-shaped blade 6 vertically. The pressing device 15 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com