Single-drive double-component fixed-proportion mixing, metering and conveying single-screw pump set, method and application thereof

A single-screw pump, single-drive technology, applied in chemical instruments and methods, mixers, fluid mixers, etc., can solve the problems of complex control system design, high cost and price, and achieve simple control system, no power supply, drive Some simple and reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

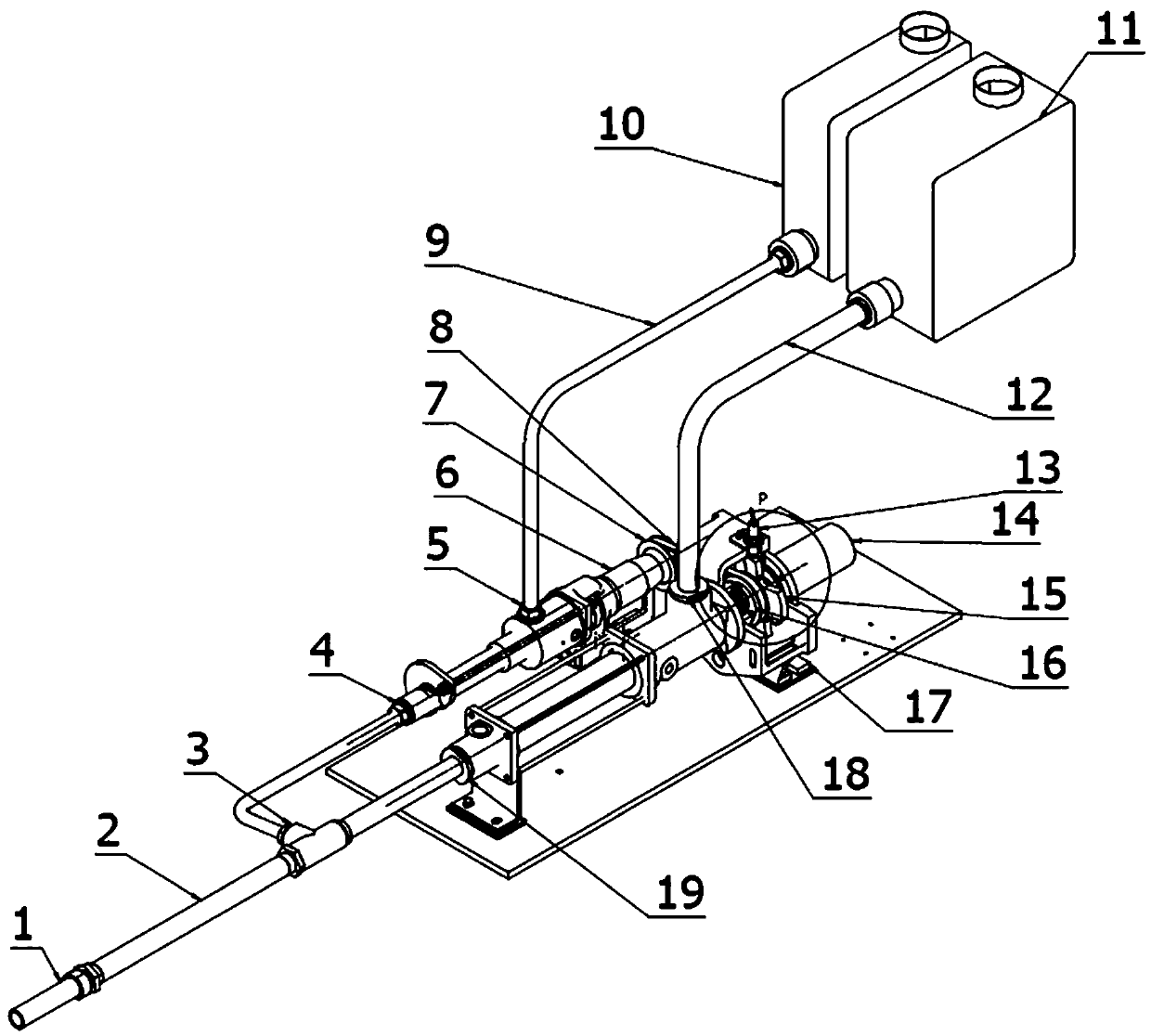

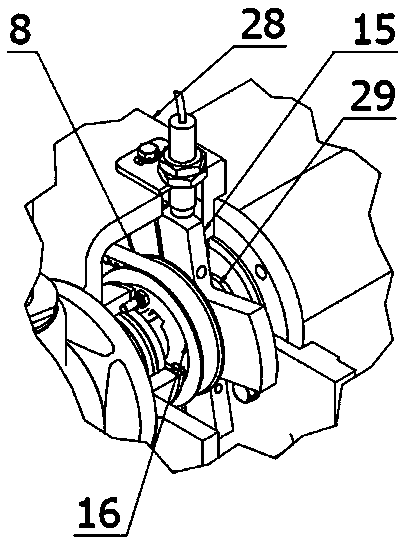

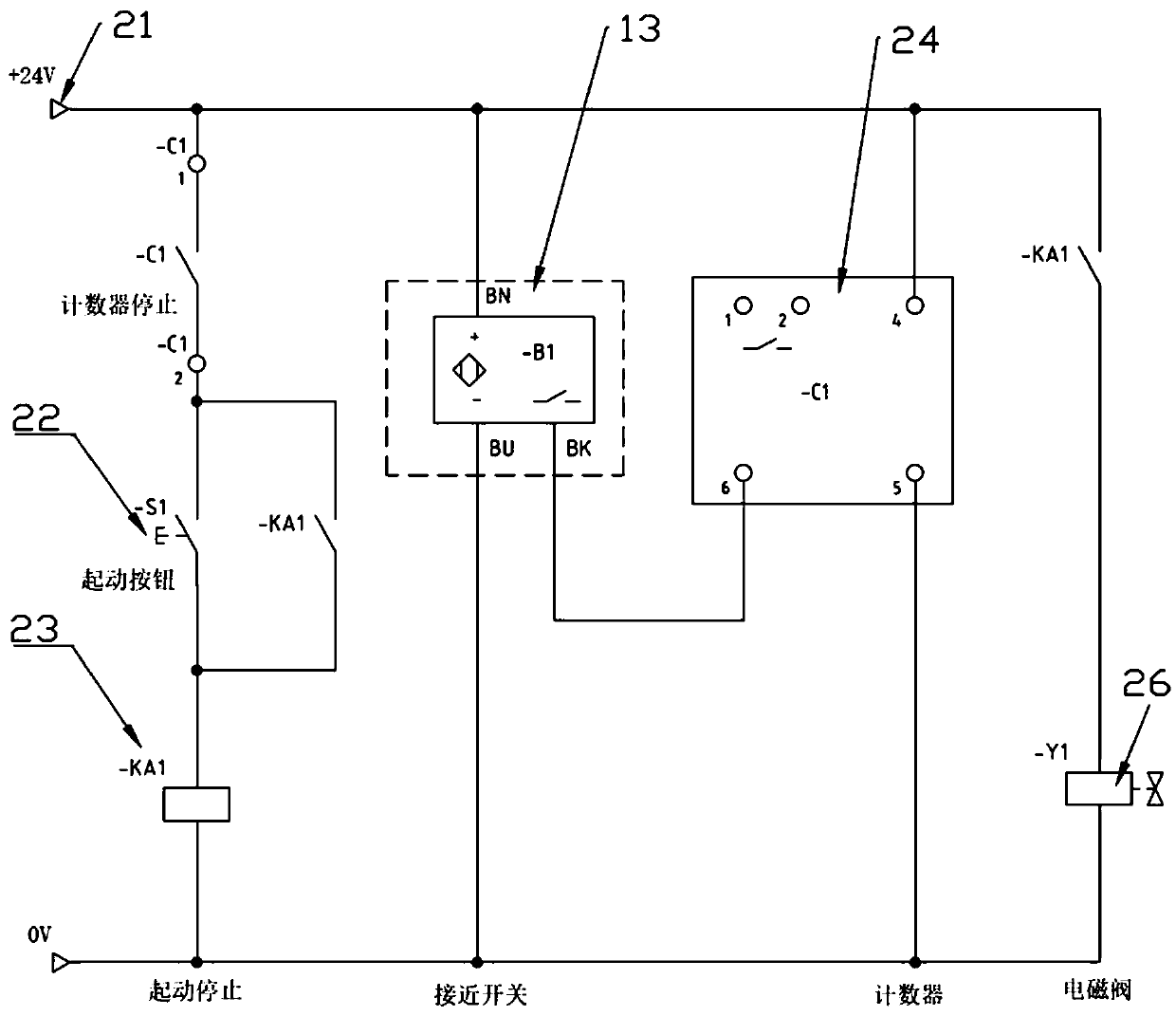

[0033] The entire control system has fewer components, such as figure 1 As shown, the direct coupling frame 28 is used to support the second pump 17, and simultaneously connects the fixed air motor 14 and the extension shaft 29, and the extension shaft is connected with the rotor in the second pump body. Second pump synchronous pulley 16 and gear plate 15 are installed on the extension shaft 29, coaxially rotated, drive first pump 6 by installing synchronous belt 8 between second pump synchronous pulley 16 and first pump synchronous pulley 7, second pump synchronous pulley 16 and first pump The pump timing pulley 7 is in the same plane. The material tank 10 of group A and the material tank 11 of group B are installed on the top of pump A 6 and pump B 17, and the liquid flows into the corresponding pump through the feed pipeline 9 of pump A and the feed pipeline 12 of pump B by its own weight. Part A is delivered to outlet 4 of pump A through pump A, component B is delivered t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com