Mushroom high-efficiency cutting machine

A foot-cutting machine, high-efficiency technology, applied in applications, food science, food processing, etc., can solve problems such as bad taste, laborious, slow progress, etc., to improve structural integrity and service life, simplify power sources, and rational use effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0035] It should be understood that terms such as "having", "comprising" and "including" as used herein do not entail the presence or addition of one or more other elements or combinations thereof.

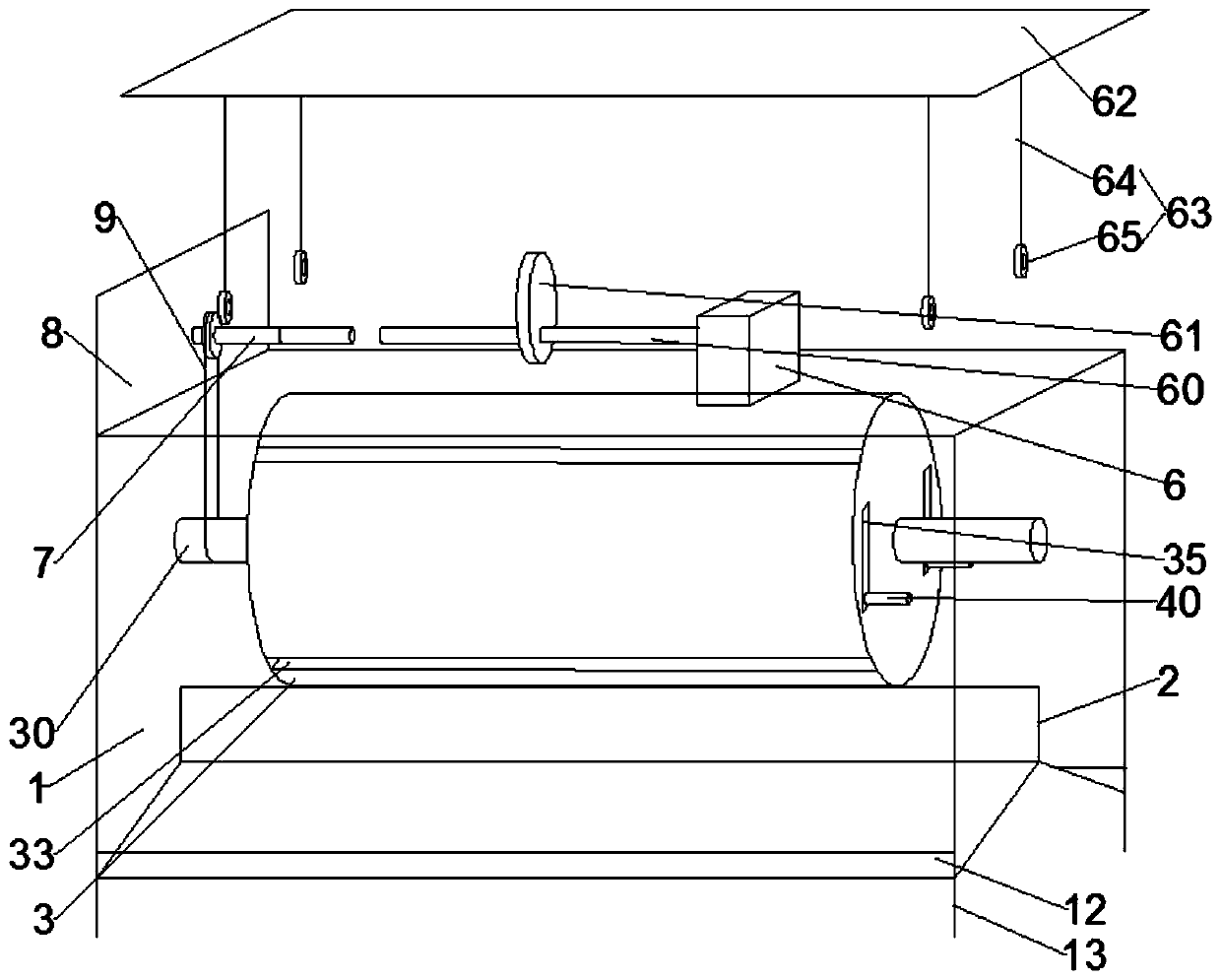

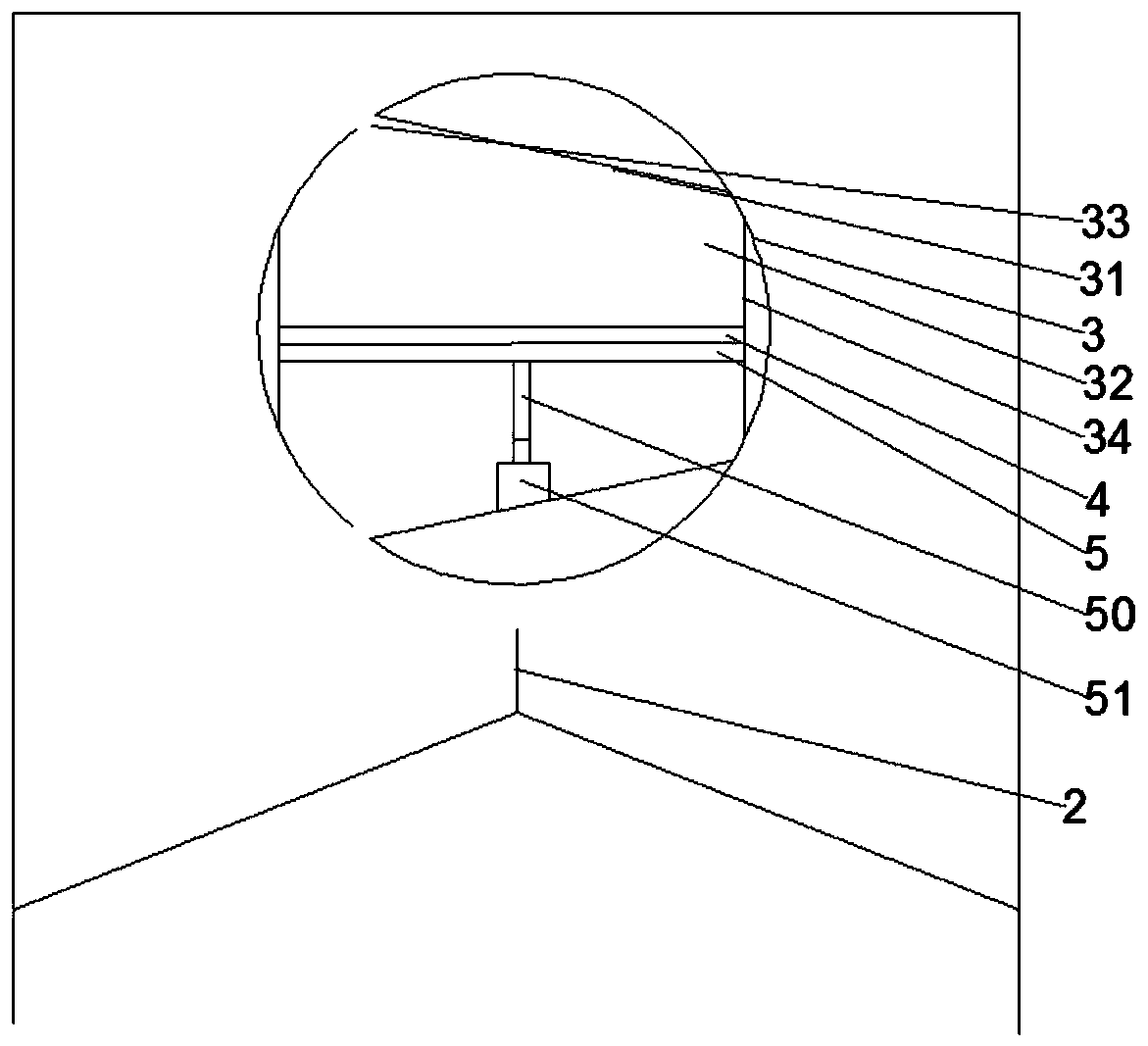

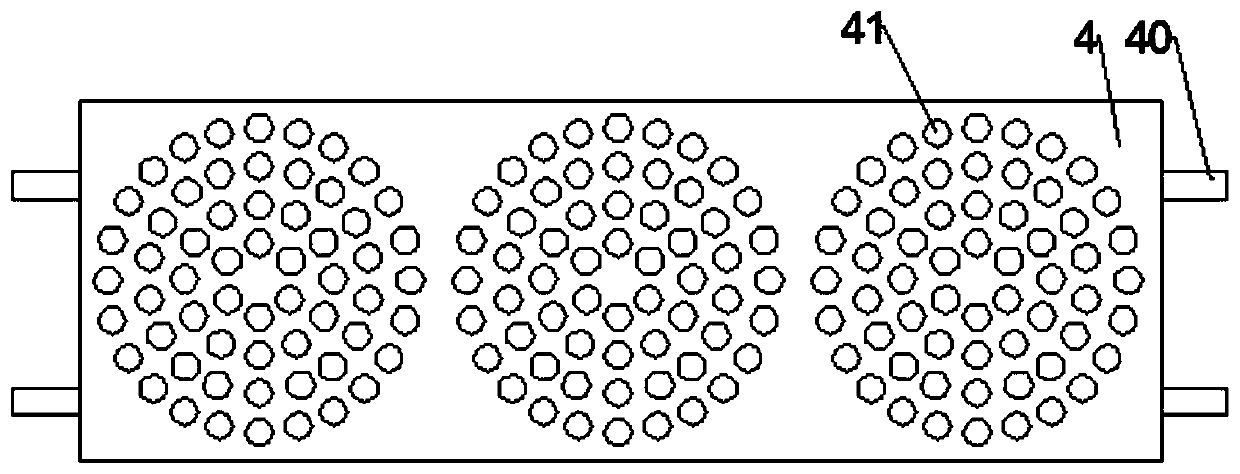

[0036] Such as Figure 1-8 As shown, the invention provides a kind of shiitake mushroom high-efficiency clipping machine, comprising:

[0037] Housing 1, which is in the shape of a cuboid, the bottom surface of the housing 1 is vertically provided with a partition 2, the partition 2 is arranged along the length direction of the bottom surface of the housing 1, and the bottom surface of the housing 1 is arranged along the width The direction is equally divided, and the lowest ends of the opposite sides of the housing 1 and the partition 2 are provided with discharge ports 12;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com